Scraper with wear-resistant layer at knife edge and production process of scraper

A production process and wear-resistant layer technology, which is applied in the field of scraper and its production process, can solve the problems of low smoothness of wear-resistant layer, low hardness of wear-resistant layer, and low density of scraper, so as to improve hardness and wear resistance , The effect of saving production cycle and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

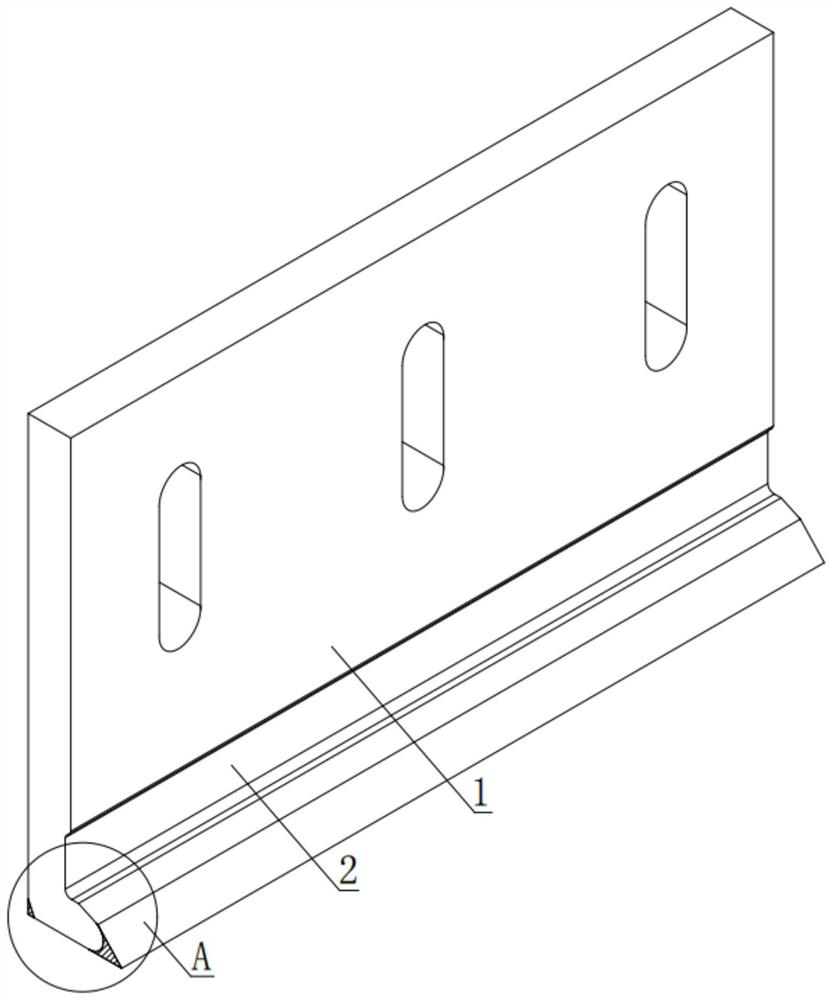

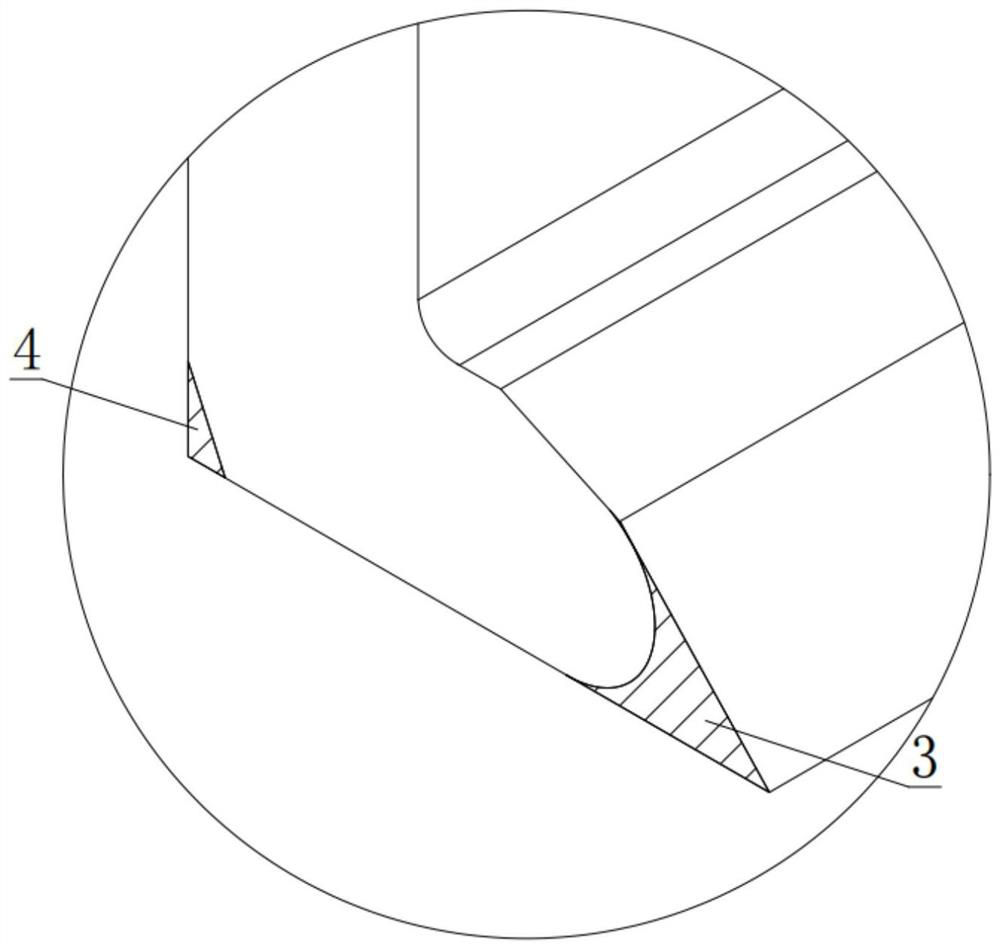

[0030] see Figure 1 to Figure 2 , a scraper with a knife edge with a wear-resistant layer, including a knife body 1, a guide groove 2, a wear-resistant layer 1 3 and a wear-resistant layer 2 4, the lower end of the knife body 1 extends forward at the knife edge, and the end of the extended part It is covered with a wear-resistant layer 3, and a guide groove 2 is opened above the knife edge. The guide groove 2 is used to guide the scraped material to both sides of the scraper. A wear-resistant layer 2 4 is provided, and the wear-resistant layer 1 3 and the wear-resistant layer 2 4 are composed of the following components by mass percentage: 60% of emery, 20% of silicon micropowder, and 20% of high-manganese steel solder.

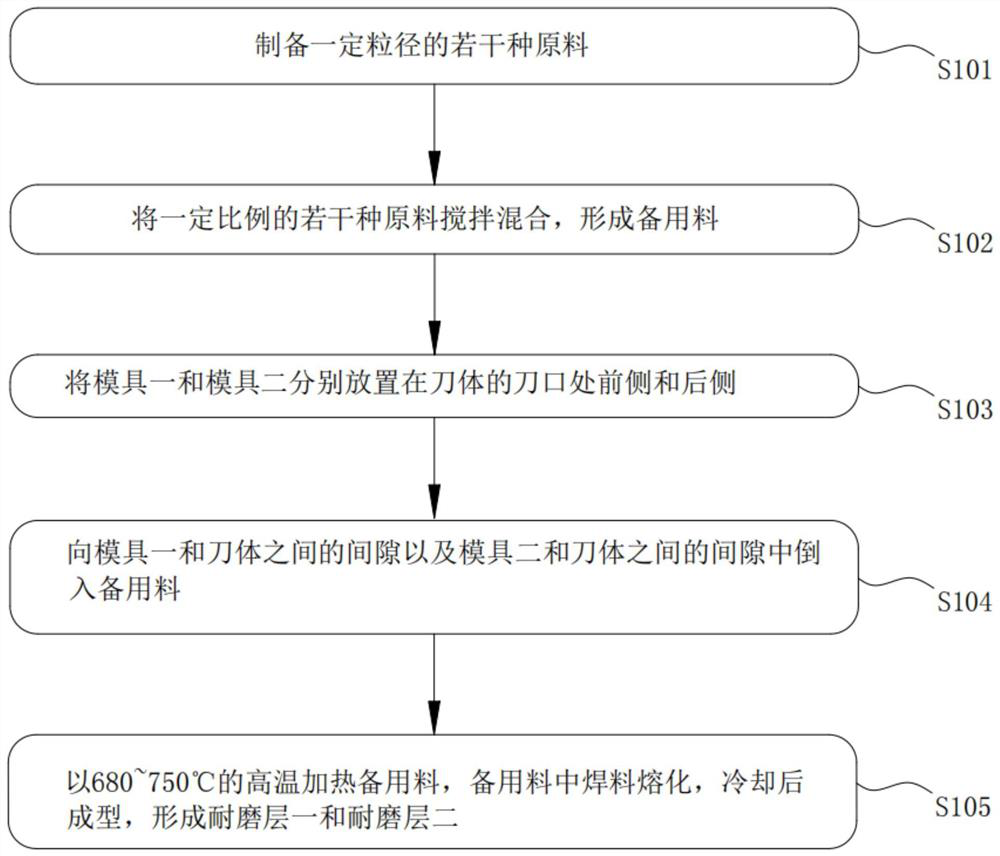

[0031] see image 3 , in order to better show the production process of the scraper with a wear-resistant layer on the knife edge, the present embodiment now proposes a production process of the scraper with a wear-resistant layer on the knife edge, includi...

Embodiment 2

[0038] The only difference between this embodiment and the first embodiment is that the constituent components of the wear-resistant layer 1 3 and the wear-resistant layer 2 4 in this embodiment are different;

[0039] The wear-resistant layer 1 3 and the wear-resistant layer 2 4 are composed of the following components by mass percentage: 20% of cemented carbide particles, 40% of emery, 20% of silicon micropowder, and 20% of high-manganese steel solder.

[0040] In order to better show the production process of the scraper with a wear-resistant layer on the knife edge, the present embodiment now proposes a production process of the scraper with a wear-resistant layer on the knife edge, including the following steps:

[0041] S101: prepare several kinds of raw materials with a certain particle size, including cemented carbide particles, emery, silicon micropowder and high-manganese steel solder, wherein the particle size of cemented carbide particles is larger than the particle...

Embodiment 3

[0047] The only difference between this embodiment and the first embodiment is that the constituent components of the wear-resistant layer 1 3 and the wear-resistant layer 2 4 in this embodiment are different;

[0048] The wear-resistant layer 1 3 and the wear-resistant layer 2 4 are composed of the following components by mass percentage: 20% of cemented carbide particles, 15% of emery, 25% of ceramic particles, 20% of silicon micropowder, and 20% of high-manganese steel solder.

[0049] In order to better show the production process of the scraper with a wear-resistant layer on the knife edge, the present embodiment now proposes a production process of the scraper with a wear-resistant layer on the knife edge, including the following steps:

[0050] S101: Prepare several kinds of raw materials with a certain particle size, including cemented carbide particles, emery, ceramic particles, silicon micropowder and high-manganese steel solder, wherein the particle size of cemented ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com