High-quality tool steel heat treatment steel strip and production method and application thereof

A heat treatment steel and production method technology, applied in the field of steel manufacturing, can solve the problems of increasing the grinding depth of semi-finished products, oxidation of the steel plate surface, and low airtightness, and achieve the effects of high flatness, saving production costs, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

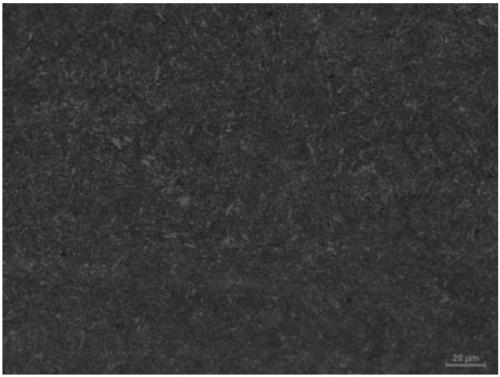

[0050] The 75Cr1 cold-rolled tool steel strip is used as the raw material, loaded into the uncoiler, welded with the leader belt, and threaded into the continuous salt bath quenching-tempering line. The moving speed of the 75Cr1 cold-rolled tool steel strip is 1.0m / min. The temperature of the austenitizing heating furnace is 940°C, and the temperature of the salt bath is 280°C. After the 75Cr1 cold-rolled tool steel is taken out of the salt bath, it is blown to cool to 20-35°C. The 75Cr1 cold-rolled tool steel strip is heat-leveled at 450°C, and then enters the tempering furnace for tempering. Coils, high-quality tool steel heat-treated steel strips are obtained.

[0051] The specifications of the high-quality tool steel heat-treated steel strip are thickness 1.5mm×width 500mm, chemical composition and mass percentage content thereof are: C 0.772%, Si 0.235%, Mn 0.755%, P 0.014%, S 0.0037%, Alt. .0203%, Ca 0.0014%, and the rest are Fe and unavoidable impurities.

Embodiment 2

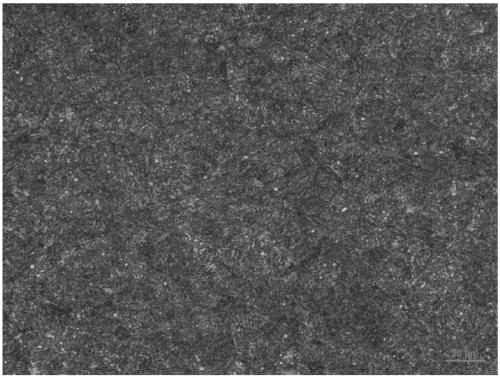

[0053] The SK4 cold-rolled tool steel strip is used as the raw material, loaded into the uncoiler, welded and combined with the leader belt, and threaded into the continuous salt bath quenching-tempering line. The moving speed of the SK4 cold-rolled tool steel strip is 1.4m / min. The temperature of the austenitizing heating furnace is 910°C, and the temperature of the salt bath is 290°C. After the 75Cr1 cold-rolled tool steel is taken out of the salt bath, it is blown to cool to 20-35°C. The SK4 cold-rolled tool steel strip is heat-leveled at 450°C, and then enters the tempering furnace for tempering. The tempering temperature is 480°C. After tempering, it is air-cooled to 20-35°C, wound and straightened on S rolls, Then it is coiled to obtain a high-quality tool steel heat-treated steel strip.

[0054] The specifications of the high-quality tool steel heat-treated steel strip are thickness 1.0mm×width 300mm, and the chemical composition and mass percentage thereof are: C 0.9...

Embodiment 3

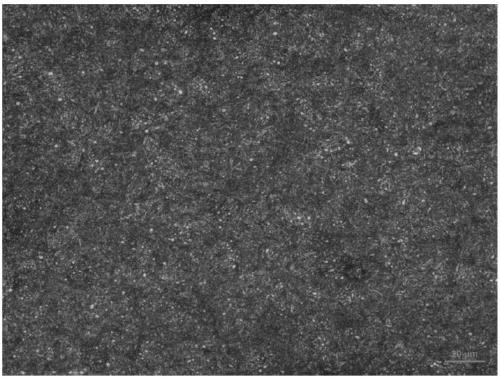

[0056] The T8 cold-rolled tool steel strip is used as raw material, loaded into the uncoiler, welded and combined with the leader belt, threaded into the continuous salt bath quenching-tempering line, and the moving speed of the T8 cold-rolled tool steel strip is 0.8m / min. The temperature of the austenitizing heating furnace is 940°C, and the temperature of the salt bath is 280°C. After the 75Cr1 cold-rolled tool steel is taken out of the salt bath, it is blown to cool to 20-35°C. The T8 cold-rolled tool steel strip is heat-leveled at 450°C, and then enters a tempering furnace for tempering at a temperature of 480°C. After tempering, it is air-cooled to 20-35°C, wound and straightened on S rolls, Then it is coiled to obtain a high-quality tool steel heat-treated steel strip.

[0057] The specifications of the high-quality tool steel heat-treated steel strip are thickness 3.0mm×width 400mm, and the chemical composition and mass percentage thereof are: C 0.805%, Si 0.188%, Mn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com