Short-flow preparation method of TA5 titanium alloy medium-thickness plate for ship

A titanium alloy and short-process technology, which is applied in the field of short-process preparation of TA5 titanium alloy medium-thick plates for ships, can solve problems such as difficult control, high energy consumption, and long cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

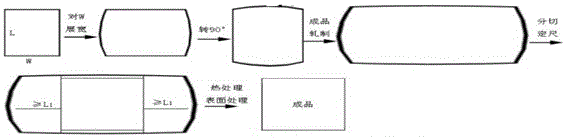

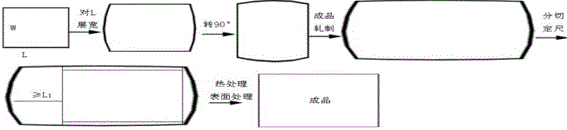

[0049] A short-process preparation method for TA5 titanium alloy medium-thick plates for ships, comprising the following steps:

[0050] Step 1, slab selection: take the TA5 titanium alloy slab, and define the length of the TA5 titanium alloy slab as , the width of the TA5 titanium alloy slab is , the thickness of TA5 titanium alloy slab is , the size of TA5 titanium alloy slab meets the following standards:

[0051] (1)

[0052] (2)

[0053] Among them, mm in the formula (1) is the length unit millimeter, and in the formula (2) is the thickness of the finished TA5 titanium alloy plate;

[0054] Step 2. Inspection slab: inspect the TA5 titanium alloy slab obtained in step 1: define the bad margin of the finished TA5 titanium alloy sheet as ;

[0055] (3)

[0056] In formula (3) are respectively the thickness, width and length dimensions of the TA5 titanium alloy slab determined in step 1, are the thickness, width and length of the finished TA5 titaniu...

example 1

[0087] First, check and select the slab: according to the finished product specification (20*1000*3000 / 1) and the requirement of the expansion deformation, the expansion deformation is selected as 15%, and the slab is selected as 130*900 according to the formula required for the selection of the slab *1030 specification slab, and widen the width of the slab (900).

[0088] Continuing from the previous step, widening and reversing rolling: ℃, rolling temperature Set to 1020°C. The widening passes are completed in two passes, and the deformation rates of the passes are 7.0% and 8.0% respectively. Then turn the billet 90° and carry out reversing rolling. After the reversing, the rolling is divided into 8 passes, and the pass deformation rates are respectively 17.1%, 18.4%, 17.3%, 19.3%, 20.0%, 20.0%, 20.3% , 19.6%. The total deformation rate of broadening and reversing rolling is 85%, and the final rolling temperature is 910°C.

[0089] Continue to the previous step, cutti...

example 2

[0093] First, check and select the slab: According to the finished product specification (22*1000*3000 / 1) and the requirement of the expansion deformation, the expansion deformation is selected as 10%, and the slab 130*800 is selected according to the formula required for the selection of the slab *960 specification slab, and widen the length of the slab (960).

[0094] Continuing from the previous step, widening and reversing rolling: ℃, rolling temperature Set to 980°C. The widening passes are completed in two passes, and the deformation rates of the passes are 4.0% and 6.0%, respectively. Then turn the billet 90° and carry out reversing rolling. After the reversing, the rolling is divided into 8 passes, and the pass deformation rates are respectively 17.1%, 20.4%, 20.3%, 20.3%, 19.0%, 19.0%, 18.3% , 17.6%. The total deformation rate of broadening and reversing rolling is 83%, and the final rolling temperature is 780°C.

[0095] Continue to the previous step, cutting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com