Method for preparing ethyl silicate and magnesium fluoride from silicon tetrafluoride, ethanol and magnesium

A silicon tetrafluoride, ethyl silicate technology, applied in magnesium fluoride, magnesium halide, silicon organic compounds and other directions, can solve problems such as unreasonable utilization of silicon tetrafluoride, achieve novel process route, extend industrial chain, simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

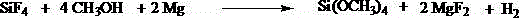

Image

Examples

Embodiment 1

[0022] Add 100 mL of ethanol and 3.0 g of 38-micron magnesium powder into the reaction kettle, stir at 78°C for 2 h, then add 29.6 g of silicon tetrafluoride ethanol solution with a mass fraction of 22% into the reaction kettle until the reaction The system is neutral. After stirring for about 2 hours, filter the reaction system, wash the filter cake with ethanol and dry to obtain magnesium fluoride. The washing solution and filtrate are combined to remove unreacted ethanol under reduced pressure to obtain ethyl silicate .

Embodiment 2

[0024] Add 100 mL of ethanol and 3.0 g of 38-micron magnesium powder into the reaction kettle, stir at 78°C for 1.5 h, then add 29.6 g of silicon tetrafluoride ethanol solution with a mass fraction of 22% into the reaction kettle until the reaction The system is neutral. After stirring for about 4 hours, filter the reaction system, wash the filter cake with ethanol and dry to obtain magnesium fluoride. The washing solution and filtrate are combined to remove unreacted ethanol under reduced pressure to obtain ethyl silicate .

Embodiment 3

[0026] Add 100 mL of ethanol and 3.0 g of magnesium powder with a size of 5 microns into the reaction kettle, and after stirring for 2 h at 40 °C, add 65.1 g of silicon tetrafluoride ethanol solution with a mass fraction of 10% into the reaction kettle until the reaction The system is neutral. After stirring for about 4 hours, filter the reaction system, wash the filter cake with ethanol and dry to obtain magnesium fluoride. The washing solution and filtrate are combined to remove unreacted ethanol under reduced pressure to obtain ethyl silicate .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com