Flanging arrangement for wall hole of thin metal pipe

A technology of metal pipe and outer flanging, which is applied in the field of mechanical processing equipment, can solve the problems of increasing the load of heat pumps, difficulty in improving production efficiency, and unsmooth water flow channels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

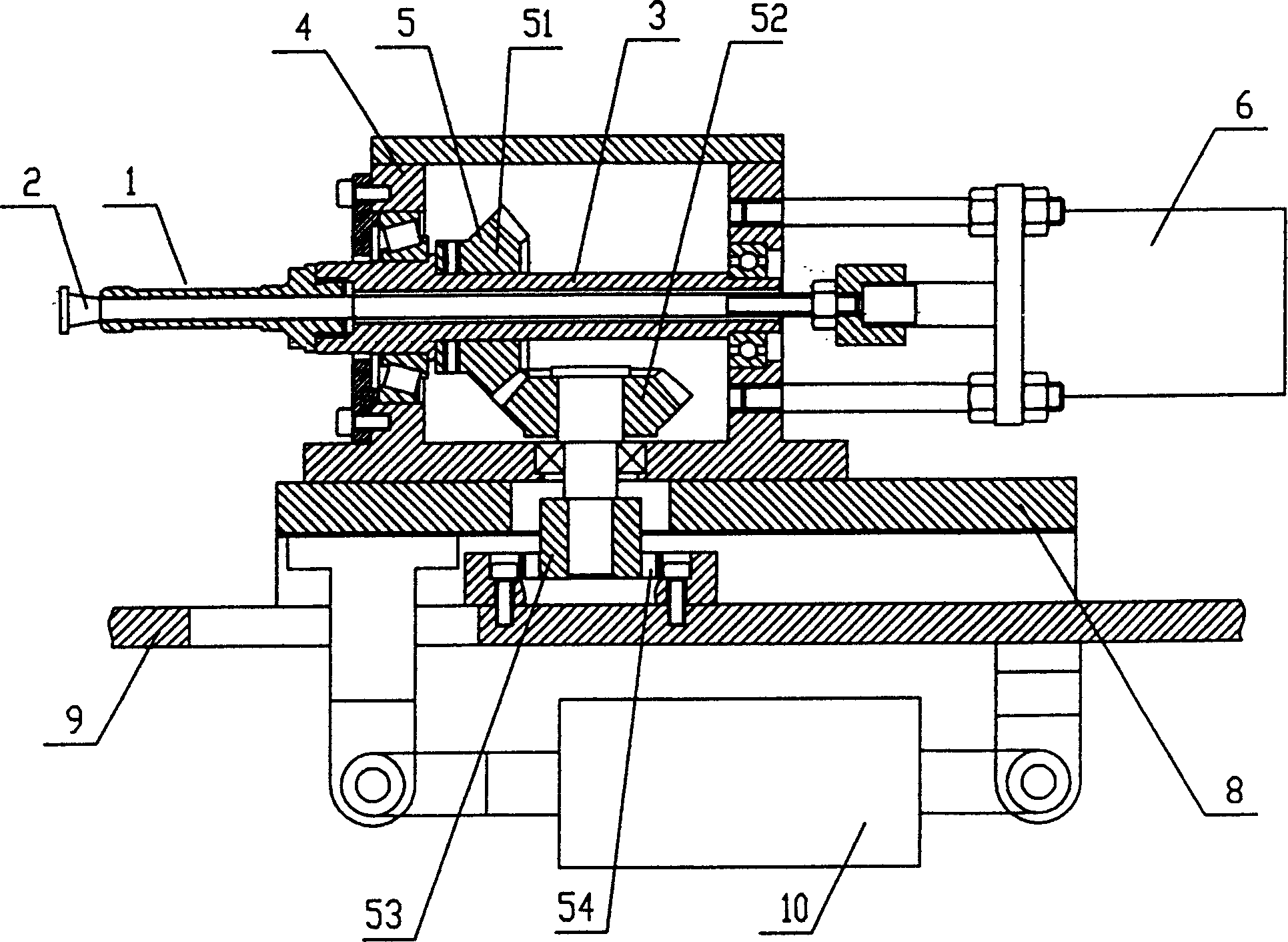

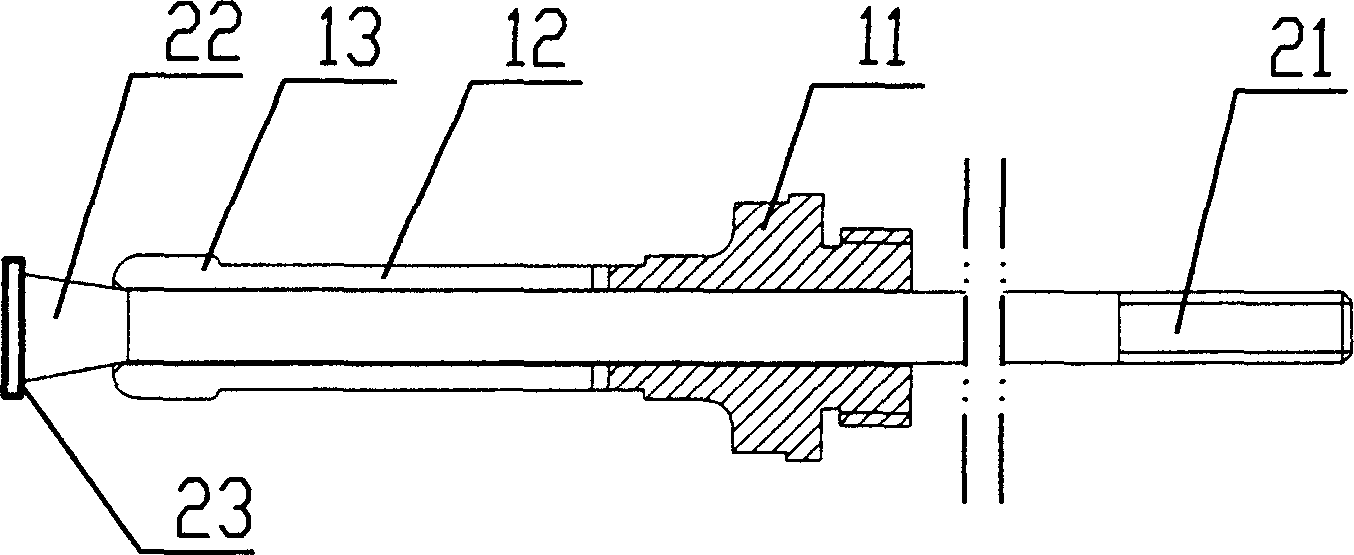

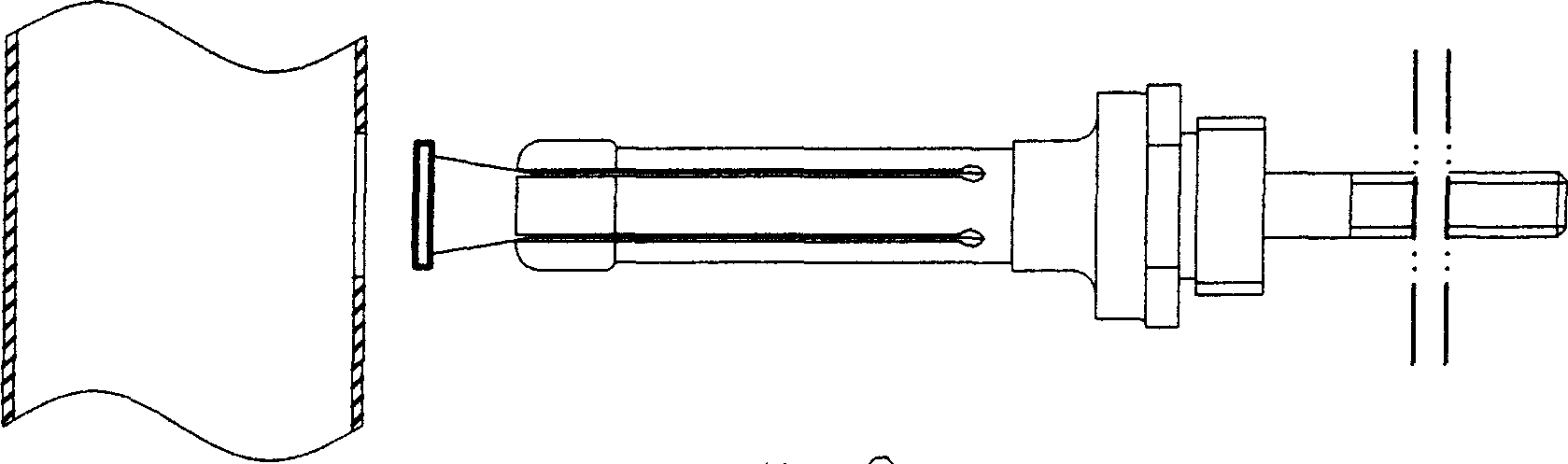

[0015] Such as figure 1 , figure 2 As shown, the flanging device for the wall hole of a thin-walled metal pipe includes a flanging tool 1 and a driving device, wherein:

[0016] The flanging cutter 1 comprises a handle 11, the front end of the handle 11 is provided with a cutter head, the cutter heads are multiple and evenly distributed along the axis of the handle 11, the cutter heads are divided into The elastic portion 12 fixedly connected to the handle 11 and the flanging edge 13 arranged at the end of the elastic portion 12, the outer edge of the flanging edge 13 is located on a common circumference and the diameter of the circumference is smaller than the diameter of the hole to be flanging, said The tool body formed by the handle 11 and some cutter heads is provided with a pull rod hole along the axis, and the pull rod 2 that can open the flanging edge 13 along the elastic part 12 is installed in the pull rod hole. After the flanging edge 13 is opened The outer edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com