Weak solvent or offset printing thermal transfer paper and production process thereof

A technology of offset printing and thermal transfer paper, applied in papermaking, paper coatings, adhesives, etc., can solve the problems of high labor cost, large number of personnel, low production efficiency, etc., to meet market demand, wide application range, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

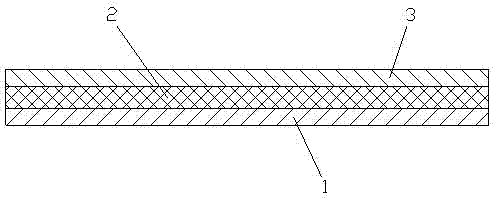

[0018] refer to figure 1 , a weak solvent or offset printing thermal transfer paper, the thermal transfer paper is sequentially provided with a paper base 1, a first thermal transfer adhesive layer 2 and a weak solvent or offset printing absorption medium layer 3 from bottom to top, The first thermal transfer adhesive layer 2 is composed of the following components by weight: 40-50% polycaprolactone polyurethane, 30-40% butadiene or styrene copolymer, 10-15% Copolyamide resin, 5~10% copolyester resin and 2~5% rosin pentaerythritol ester.

[0019] In this embodiment, the paper base 1 uses PET (polyester film), glassine paper, CCK paper (Clay Coated Craft Paper) or double-sided PEK paper (coated release paper), and the paper base 1 The peel strength is 250~650g / inch.

[0020] In this embodiment, the weak solvent or offset printing absorption medium la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com