Preparation method of fluorine-doped lithium-rich manganese-based positive electrode material

A lithium-rich manganese-based, cathode material technology, used in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems that products are difficult to reach the atomic level, difficult to achieve industrial application, poor mixing uniformity, etc., and achieve cycle performance. The effect of lifting, mild and controllable conditions, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

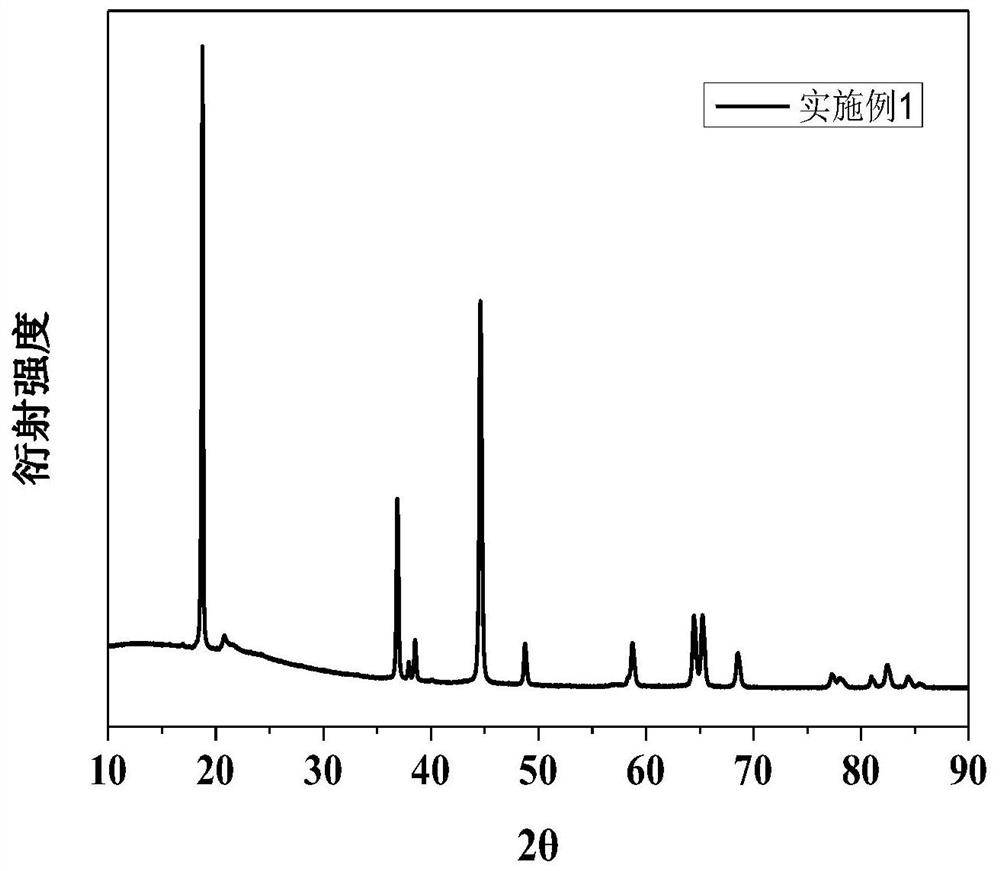

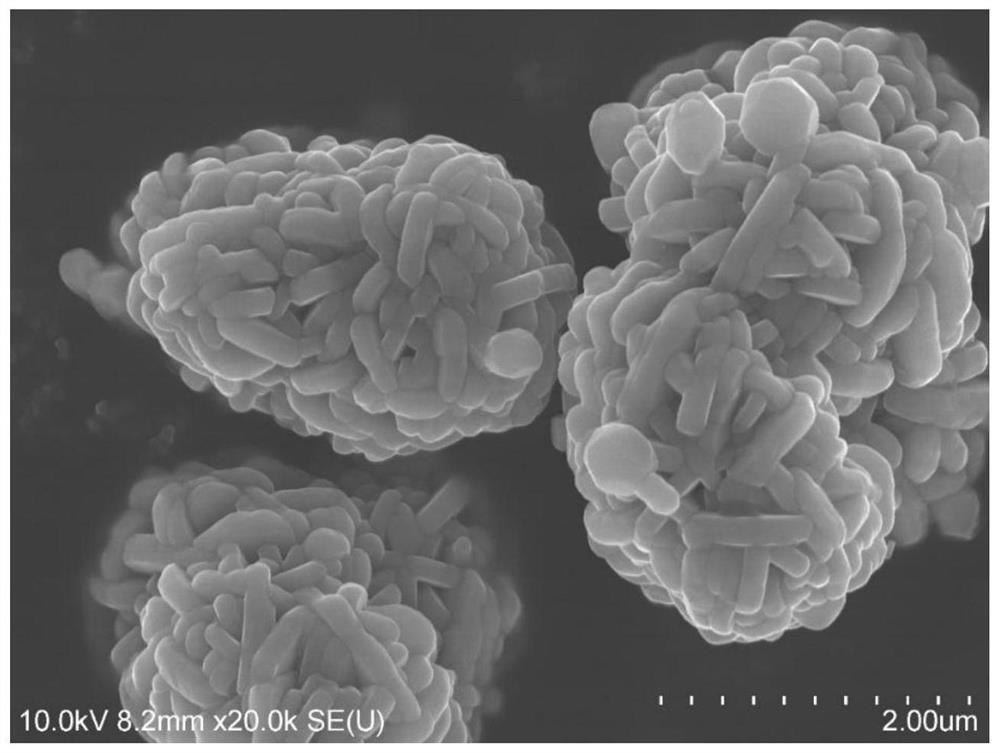

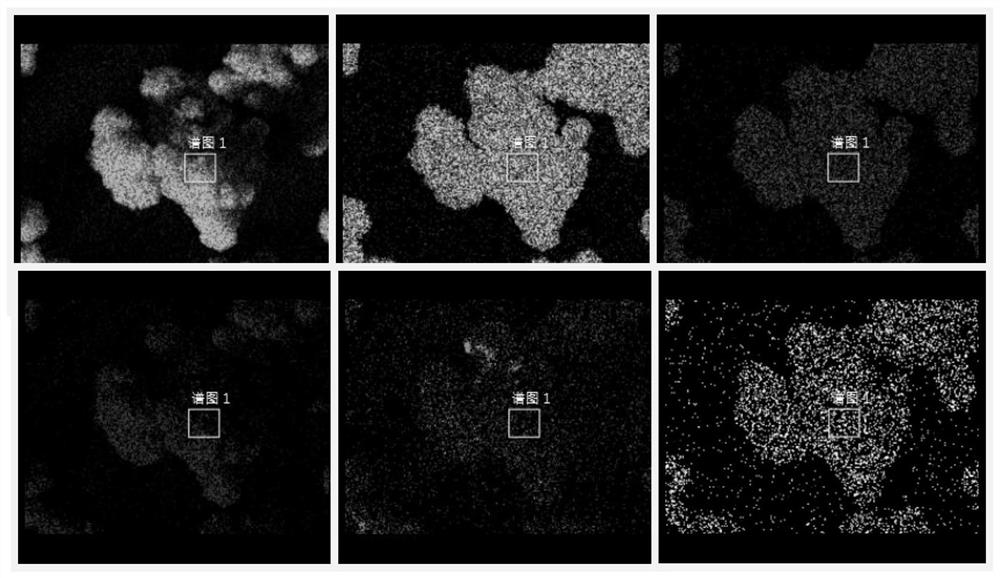

[0043] Weigh manganese sulfate monohydrate, nickel sulfate hexahydrate and cobalt sulfate heptahydrate according to the molar ratio of 8:4:1, dissolve them in deionized water to prepare 2mol / L metal salt solution A; dissolve sodium carbonate in water to prepare 2mol / L Precipitating agent solution B, then add ammonium fluoride, and stir until completely dissolved to obtain solution C, wherein the molar ratio of ammonium fluoride to sodium carbonate is controlled to be 5:100; under the stirring condition of 500rpm / min, the solution A and C are slowly added dropwise to deionized water, the pH of the reaction system is controlled to be 8, and the temperature of the system is 55°C. After 20 hours of reaction, the obtained precipitate is washed, filtered and dried to obtain a fluorine-doped lithium-rich manganese base Precursor (Mn 8 / 13 Ni 4 / 13 co 1 / 13 f 0.01 )CO 3 ;

[0044] The fluorine-doped lithium-rich manganese-based precursor was mixed with lithium carbonate at a molar r...

Embodiment 2

[0051] Weigh manganese sulfate monohydrate, nickel sulfate hexahydrate and cobalt sulfate heptahydrate according to the molar ratio of 8:4:1, dissolve in deionized water to prepare 2mol / L metal salt solution A; dissolve sodium carbonate in water to prepare 2mol / L Precipitating agent solution B, then add ammonium fluoride, and stir until completely dissolved to obtain solution C. Control the molar ratio of ammonium fluoride to sodium carbonate to be 10:100; under the stirring condition of 800rpm / min, mix solution A and C is slowly added dropwise to deionized water, the pH of the reaction system is controlled to be 8, and the temperature of the system is 55°C. After 20 hours of reaction, the obtained precipitate is washed, filtered and dried to obtain a fluorine-doped lithium-rich manganese-based precursor. (Mn 8 / 13 Ni 4 / 13 co 1 / 13 f 0.02 )CO 3 ;

[0052] The fluorine-doped lithium-rich manganese-based precursor was uniformly mixed with lithium carbonate at a molar ratio ...

Embodiment 3

[0055] Weigh manganese nitrate monohydrate, nickel nitrate hexahydrate and cobalt nitrate hexahydrate according to the molar ratio of 7.93:4.77:1, dissolve in deionized water to prepare 2mol / L metal salt solution A; dissolve potassium carbonate in water to prepare 2mol / L Precipitating agent solution B, then add potassium fluoride, stir until completely dissolved to obtain solution C, control the molar ratio of potassium fluoride to potassium carbonate to be 15:100; under 1000rpm / min stirring condition, mix solution A and C is slowly added dropwise to deionized water, the pH of the reaction system is controlled to be 7.5, and the temperature of the system is 50°C. After 15 hours of reaction, the obtained precipitate is washed, filtered and dried to obtain a fluorine-doped lithium-rich manganese-based precursor. (Mn 0.579 Ni 0.348 co 0.073 f 0.03 )CO 3 ;

[0056] Mix the fluorine-doped lithium-rich manganese-based precursor with lithium hydroxide at a molar ratio of 1:1.12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com