Method for stabilizing/curing soluble phosphorus and fluorine in phosphogypsum

A phosphogypsum, soluble technology, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of reducing the moisture content of phosphogypsum, the harmless treatment of phosphogypsum is not thorough enough, high energy consumption, etc. , the effect of reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for stabilizing / solidifying soluble phosphorus and fluorine in phosphogypsum, using treatment agents including calcium carbonate (CaCO 3 ), magnesium carbonate (MgCO 3 ), calcium hydroxide (Ca(OH) 2 ) and polydimethylsiloxane, is characterized in that, comprises the following steps:

[0039] 1) Put phosphogypsum in container A, add water to container A under stirring, then add mixture A, and obtain mixture B after stirring;

[0040] Said mixture A comprises calcium carbonate, magnesium carbonate and calcium hydroxide;

[0041] The water content of the phosphogypsum is 20% to 30%;

[0042] The weight ratio of the phosphogypsum to water is 1:2.5;

[0043] The weight ratio of described calcium carbonate, magnesium carbonate and calcium hydroxide is 1: 1: 1;

[0044] The weight ratio of the mixture A to phosphogypsum is 0.5:100;

[0045] In the stirring state: the stirring rate is 100r / min.

[0046] 2) In a stirring state, add a hydrophobic surfactant to con...

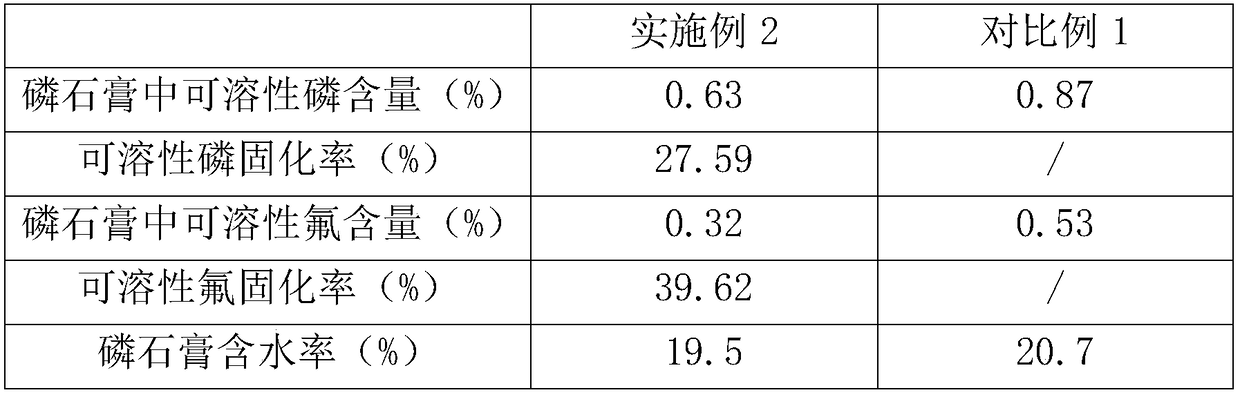

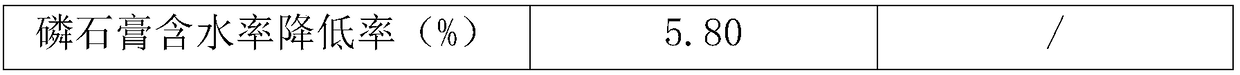

Embodiment 2

[0058] A method for stabilizing / solidifying soluble phosphorus and fluorine in phosphogypsum, using treatment agents including calcium carbonate (CaCO 3 ), magnesium carbonate (MgCO 3 ), calcium hydroxide (Ca(OH) 2 ) and polydimethylsiloxane, is characterized in that, comprises the following steps:

[0059] 1) Put phosphogypsum in container A, add water to container A under stirring, then add mixture A, and obtain mixture B after stirring;

[0060] Said mixture A comprises calcium carbonate, magnesium carbonate and calcium hydroxide;

[0061] The water content of the phosphogypsum is 20% to 30%;

[0062] The weight ratio of the phosphogypsum to water is 1:2.5;

[0063] The weight ratio of described calcium carbonate, magnesium carbonate and calcium hydroxide is 1: 1: 1;

[0064] The weight ratio of the mixture A to phosphogypsum is 0.5:100;

[0065] In the stirring state: the stirring rate is 100r / min.

[0066] 2) In a stirring state, add a hydrophobic surfactant to con...

Embodiment 3

[0079] A method for stabilizing / solidifying soluble phosphorus and fluorine in phosphogypsum, using treatment agents including calcium carbonate (CaCO 3 ), magnesium carbonate (MgCO 3 ), calcium hydroxide (Ca(OH) 2 ) and polydimethylsiloxane, is characterized in that, comprises the following steps:

[0080] 1) Put phosphogypsum in container A, add water to container A under stirring, then add mixture A, and obtain mixture B after stirring;

[0081] Said mixture A comprises calcium carbonate, magnesium carbonate and calcium hydroxide;

[0082] The water content of the phosphogypsum is 20% to 30%;

[0083] The weight ratio of the phosphogypsum to water is 1:2.5;

[0084] The weight ratio of described calcium carbonate, magnesium carbonate and calcium hydroxide is 1: 1: 1;

[0085] The weight ratio of the mixture A to phosphogypsum (0.5: 100;

[0086] In the stirring state: the stirring rate is 100r / min.

[0087] 2) In a stirring state, add a hydrophobic surfactant to cont...

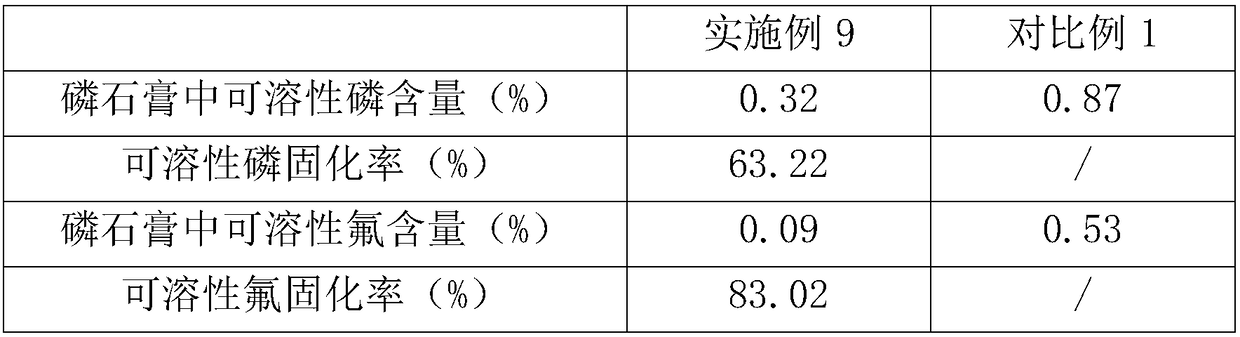

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com