Caffeine production wastewater treatment method

A treatment method and technology for producing wastewater, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. The effect of reducing operation and management cost, improving processing effect and reducing operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

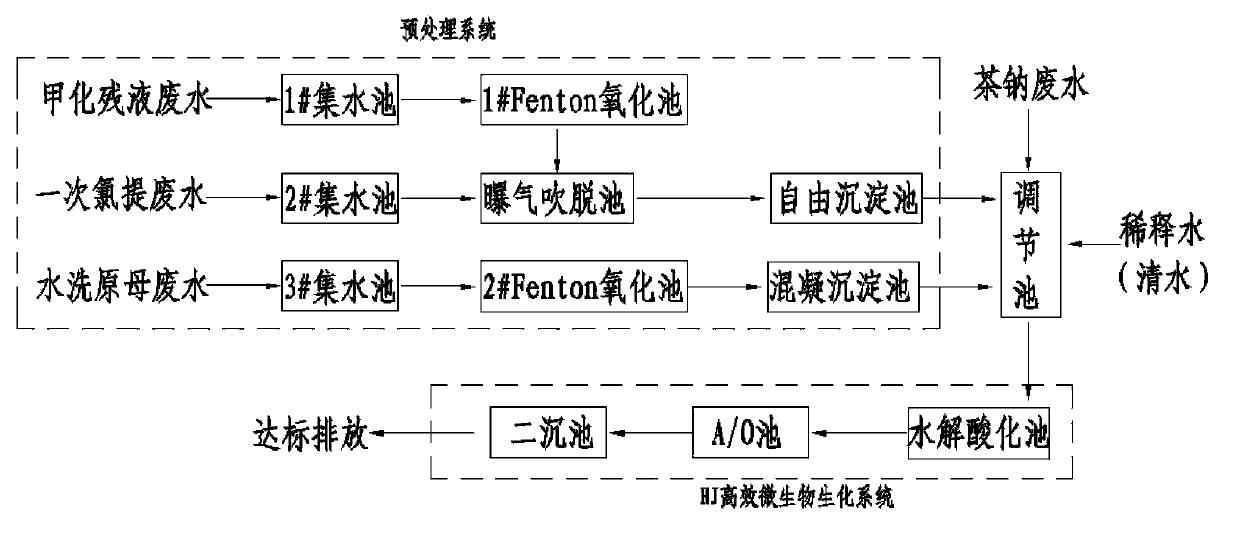

[0031] Example 1, see figure 1 , respectively collect the methylated raffinate wastewater, primary chlorination wastewater and water washing wastewater into the 1# sump, 2# sump and 3# sump, and raise the formazan raffinate wastewater in the 1# sump to In the 1#Fenton oxidation tank, adjust the pH to 2, add 5~20kg of ferrous sulfate aqueous solution with a mass fraction of 5~50% and 2~20L of hydrogen peroxide with a mass fraction of 30% in each cubic meter of methylated raffinate wastewater, Carry out the Fenton oxidation reaction; at the same time, discharge the primary chlorination wastewater in the 2# sump into the aeration stripping tank, control the temperature of the wastewater in the reaction tank to 30 ° C, adjust the pH to 6, and drain the 1# oxidation tank through The oxidized methylated raffinate waste water is brought into the aeration and stripping tank, mixed with the primary chlorination waste water and aerated and stripped for 0.5h, and then discharged into the...

Embodiment 2

[0033] Embodiment 2, respectively collect the methylated raffinate wastewater, primary chlorination wastewater and water washing former mother wastewater into 1# sump, 2# sump and 3# sump, and the methylated raffinate in the 1# sump Lift the wastewater into the 1#Fenton oxidation pond, adjust the pH to 6, and add 5~20kg of ferrous sulfate aqueous solution with a mass fraction of 5~50% and 2~20L with a mass fraction of 30% for each cubic meter of methylated raffinate wastewater Hydrogen peroxide, carry out the Fenton oxidation reaction; at the same time, discharge the primary chlorination wastewater in the 2# sump into the aeration stripping tank, control the temperature of the wastewater in the reaction tank to 80°C, adjust the pH to 14, and oxidize the 1# The oxidized first formaldehyde waste water in the pool is poured into the aeration and stripping tank, mixed with the primary chlorination wastewater and aerated and stripped for 5 hours, and then discharged into the free se...

Embodiment 3

[0035] Embodiment 3, respectively collect first formazan raffinate waste water, primary chlorination waste water and water washing former mother waste water in 1# sump, 2# sump and 3# sump, and the formazan raffinate in 1# sump Lift the wastewater into the 1#Fenton oxidation pond, adjust the pH to 3, and add 5~20kg of ferrous sulfate aqueous solution with a mass fraction of 5~50% and 2~20L with a mass fraction of 30% for each cubic meter of methylated raffinate wastewater Hydrogen peroxide, carry out the Fenton oxidation reaction; at the same time, discharge the primary chlorination wastewater in the 2# sump into the aeration stripping tank, control the temperature of the wastewater in the reaction tank to 40°C, adjust the pH to 7, and oxidize the 1# The oxidized first-formation raffinate wastewater in the pool is poured into the aeration blow-off tank, mixed with the primary chlorination wastewater for aeration and blow-off for 1 hour, and then discharged into the free sedimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com