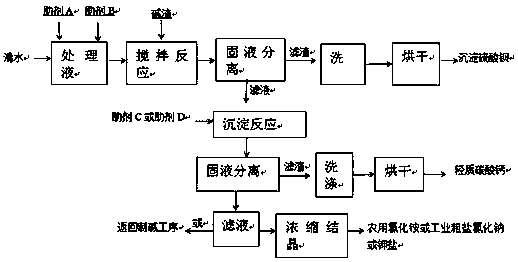

Comprehensive waste soda ash residue recycling method

A technology of waste slag and soda ash, applied in the fields of application, alkali metal chloride, nitrogen fertilizer, etc., can solve the problems of unsatisfactory recovery and treatment of alkali slag, achieve considerable benefits, reduce production costs, and simplify the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Measure 1000ml of water into the reaction mixing tank, weigh BaCO 3 84.2 g of barium carbonate with a content of 99% was added to the mixing tank while stirring. Measure 446ml of hydrochloric acid solution with an HCl content of 37%, and slowly add it into the mixing tank. After the barium carbonate is completely dissolved, weigh 500g of alkali residue from Guangdong Nanfang Soda Manufacturing Co., Ltd., and slowly add it into the mixing tank while stirring, and stir until the sample is collected. Stop stirring when it is detected that the precipitate does not contain calcium ions. Then use a centrifuge for solid-liquid separation, put the filtrate into a mixing tank, and wash the filter cake with water until the washing liquid has no Clˉions. And dried at 105 degrees centigrade to constant weight to obtain 98.5 g of precipitated barium sulfate powder.

[0036] 2. Weigh 240g of sodium carbonate powder, start the mixer and slowly add it into the mixing bucket while ...

Embodiment 2

[0039] 1. Measure 1000ml of clear water and put it into the reaction mixing bucket, weigh 84.2g of barium carbonate powder, add it into the mixing bucket while stirring, measure 446ml of 37% hydrochloric acid and slowly add it into the mixing bucket until the barium carbonate is completely dissolved Then weigh 500g of alkali slag from Guangdong Nanfang Soda Manufacturing Co., Ltd., slowly add it to the mixing tank while stirring, and stop stirring until the sediment is free of calcium ions after sampling. bucket, the filter cake is washed with clear water until the washing liquid does not contain Cl ˉ ions, put into an oven and dry at a temperature of 105 degrees Celsius to constant weight to obtain 98.5g of precipitated barium sulfate.

[0040] 2. Weigh 180g of ammonium bicarbonate powder, start the mixer and slowly add it into the mixing bucket while stirring, stop stirring until no bubbles are generated in the bucket, use a centrifuge for solid-liquid separation, add the fil...

Embodiment 3

[0043] With an annual output of 10,000 tons of soda ash waste residue, 1,970 tons of barium sulfate, 5,240 tons of light calcium carbonate, and 5,740 tons of ammonium chloride fertilizer can be recovered, saving 2,866 tons of raw materials for the country and reducing the amount of pollutant discharge. It avoids environmental pollution and protects the environment. It can also make multiple processes by itself or cooperate with other enterprises to make full use of barium sulfate, light calcium carbonate, and ammonium chloride fertilizers recovered from soda ash waste residue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com