Process and device for treating high-hardness and high-alkalinity strong brine from iron and steel plants

A treatment process, high alkalinity technology, applied in water/sewage treatment, metallurgical wastewater treatment, water treatment parameter control, etc., can solve the problems of poor pretreatment water quality, large floor area, reverse osmosis fouling, etc., to achieve Effects of avoiding pollution, reducing facility footprint, and small concentrated water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

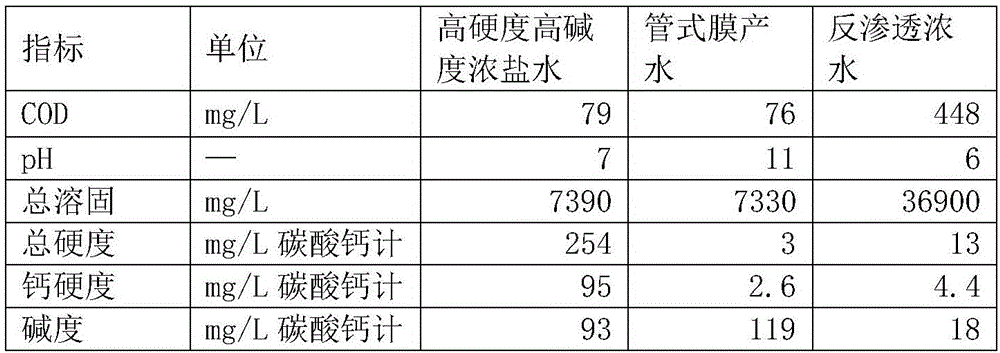

[0031] See the table below for relevant water quality.

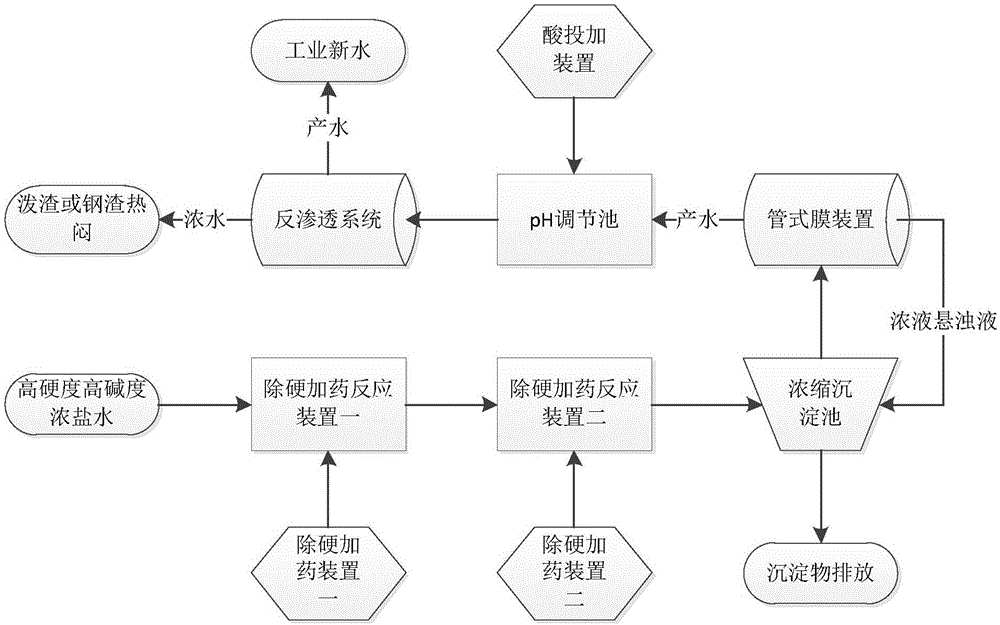

[0032] (1) Concentrated salt water with high hardness and high alkalinity first enters the dosing and removing hardness reaction device for two-stage dosing. The first stage adds 100mg / L calcium hydroxide, and the reaction is mixed for 1 minute to keep the pH in the pool above 9.8; Add 100mg / L sodium hydroxide in the second stage, mix and react for 1 minute, and keep the pH in the pool at about 11; (2) The high-hardness and high-alkalinity concentrated brine that has been mixed with the drug enters the concentrated sedimentation tank, and the residence time of the concentrated sedimentation tank is 2 minutes, control the solid content at 0.1%; (3) The mixed solution formed by the high hardness and high alkalinity concentrated brine and the sediment in the concentrated sedimentation tank enters the tubular microfiltration membrane for circulation filtration, and the water after hardness removal enters the pH adjustment (4...

Embodiment 2

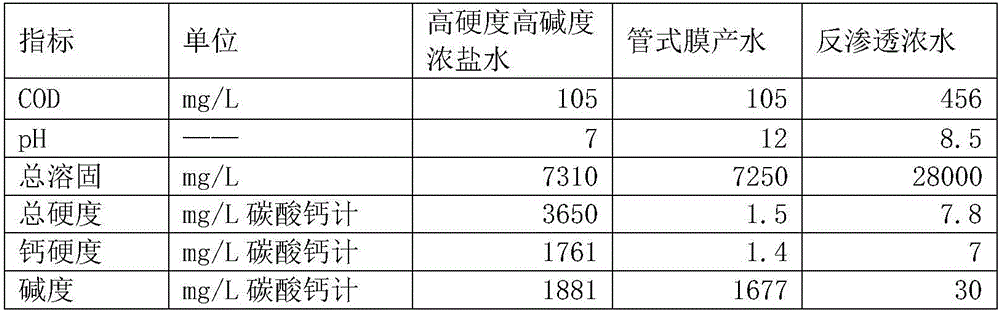

[0036] See the table below for relevant water quality.

[0037] (1) Concentrated salt water with high hardness and high alkalinity first enters the dosing and removing hardness reaction device for two-stage dosing. The first stage is to add 2000mg / L sodium hydroxide, and the reaction is mixed for 60 minutes to keep the pH in the pool at about 10.8; Add 2000mg / L sodium hydroxide in the second stage, mix and react for 60 minutes, and keep the pH in the pool at about 12; (2) The high-hardness and high-alkalinity concentrated brine that has been mixed with the drug enters the concentrated sedimentation tank, and the residence time of the concentrated sedimentation tank is 120 minutes, control the solid content at 10%; (3) The mixed solution formed by the high hardness and high alkalinity concentrated brine and the sediment in the concentrated sedimentation tank enters the tubular microfiltration membrane for circulation filtration, and the water after hardness removal enters the pH...

Embodiment 3

[0041] See the table below for relevant water quality.

[0042] (1) Concentrated salt water with high hardness and high alkalinity first enters the dosing and removing hardness reaction device for two-stage dosing. The first stage is to add 810mg / L sodium hydroxide, and the reaction is mixed for 15 minutes to keep the pH in the pool at about 10.3; Add 442mg / L sodium hydroxide in the second stage, mix and react for 15 minutes, and keep the pH in the pool at about 11.3; (2) The high-hardness and high-alkalinity concentrated brine that has been mixed with the drug enters the concentrated sedimentation tank, and the residence time of the concentrated sedimentation tank is For 30 minutes, control the solid content between 4% and 5%; (3) The mixed solution formed by the high hardness and high alkalinity concentrated brine and the sediment in the concentrated sedimentation tank enters the tubular microfiltration membrane for circulation filtration, and passes through the hardness remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com