Process for reclaiming and treating phosphorization sewage

A treatment method and sewage recycling technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, etc., can solve the waste of water resources, increase operating costs, and increase process flow , operation difficulty and other issues, to achieve the effect of reducing treatment cost, convenient operation, and solving the problem of sewage discharge not up to standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

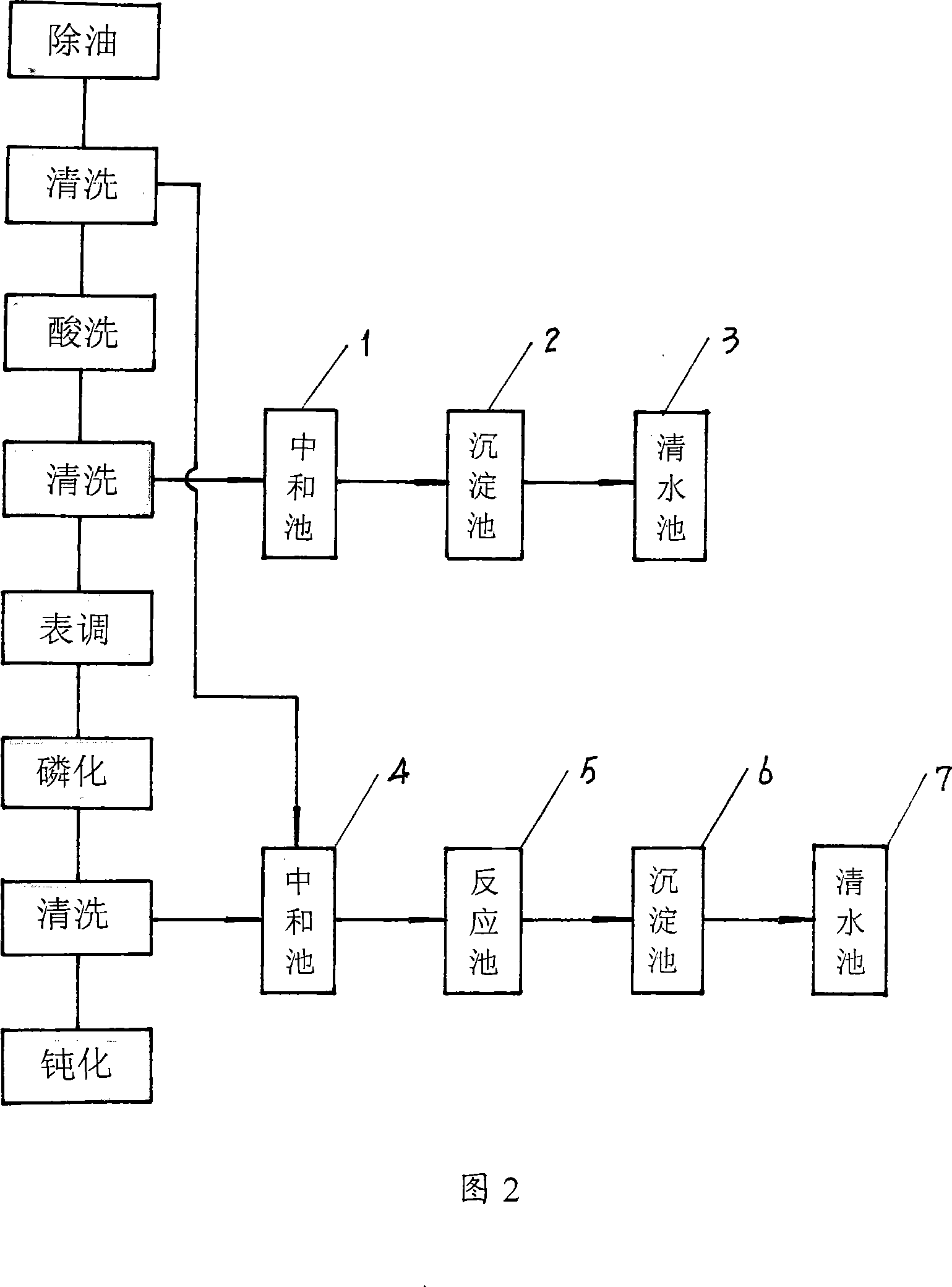

[0018] Shown in Fig. 2, be the specific embodiment of phosphating sewage recovery treatment method of the present invention, it comprises the steps:

[0019] 1) Add caustic soda or sulfuric acid to the neutralization tank 4 to neutralize the sewage produced in the degreasing process and the phosphating process, so that the pH value of the sewage in the neutralization tank 4 is controlled at 7-9 ;

[0020] 2) The neutralized treated water enters the reaction tank 5, and coagulants such as polyphosphoric acid, ferric chloride and polyaluminum chloride are added in an amount of 3-8.0 mg / L respectively, and rapid stirring is carried out for 1-2 minutes , so that the coagulant is evenly distributed, and then stirred at a slow speed for 15 to 30 minutes, which is conducive to coagulation. The treated water and oil in the reaction tank 5 are controlled at ≤1.0mg, the total phosphorus is controlled at ≤1.0mg, and the zinc is controlled at ≤3.2 mg;

[0021] 3), the treated water afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com