Harmless disposal and resource utilization method for electroplating sludge

A technology for electroplating sludge and recycling, applied in the direction of improving process efficiency, etc., can solve the problems of difficulty in recycling leaching slag and secondary sedimentation slag, incomplete metal separation, and difficulty in large-scale production, so as to improve quality and additional Value, thorough detoxification, and strong adaptability to environmental factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

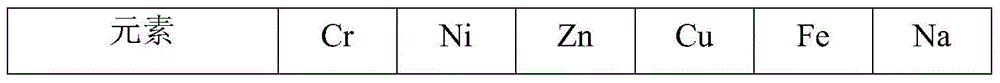

[0032] The raw material used is electroplating sludge produced by a wastewater treatment plant in an electroplating park in Guangdong, and its chemical composition is shown in Table 1.

[0033] Table 1 Example 1 dry base electroplating sludge main chemical composition

[0034] the element

Cr

Ni

Zn

Cu

Fe

Na

Content %

2.83

7.28

0.29

1.70

0.89

0.404

[0035] A process for harmless disposal and resource utilization of electroplating sludge containing chromium, iron, nickel, copper and zinc, comprising the following steps:

[0036] (1) The microorganisms used for leaching are Ferroplasma acidiphilum, Acidithiobacillus ferrivorans, Acidithiobacillus ferrooxidans, Leptospirilum ferriphilum, acidophilus Sulfobacillus acidophilus and Ferroplasmathermophilum are mixed cultures obtained by domestication in the corresponding electroplating sludge system at 30°C.

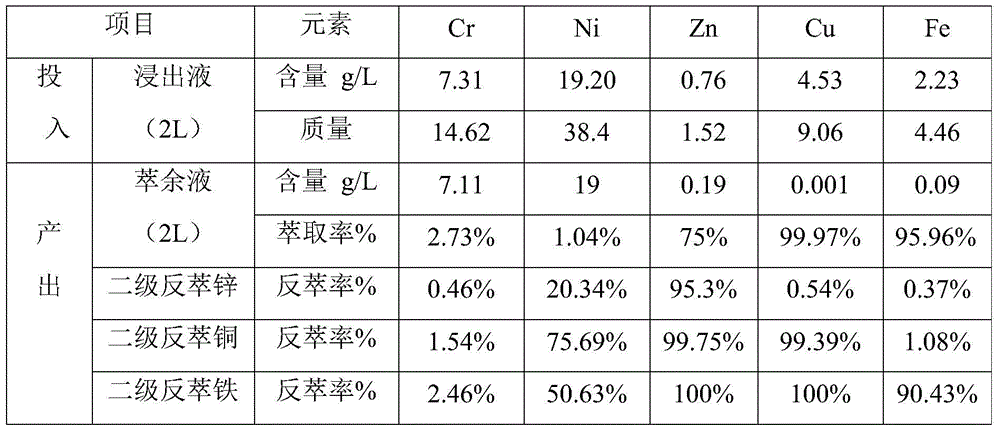

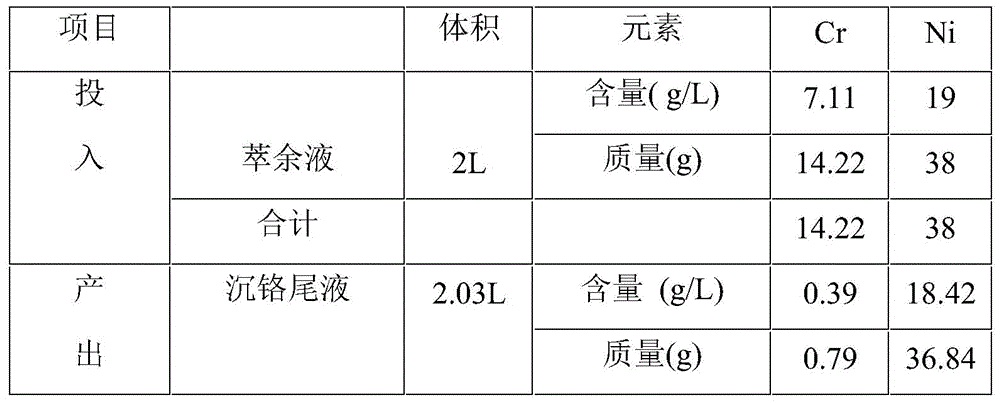

[0037] (2) The bioleaching process is carried out in a 1...

Embodiment 2

[0051] The raw material used is electroplating sludge discharged from an electroplating factory in Shenzhen, and its chemical composition is shown in Table 5.

[0052] Table 5 Example 2 The main chemical components of dry base electroplating sludge

[0053] the element

Cr

Ni

Zn

Cu

Fe

Na

Content %

3.26

2.45

1.75

2.95

7.73

0.11

[0054] A process for harmless disposal and resource utilization of electroplating sludge containing chromium, iron, nickel, copper and zinc, comprising the following steps:

[0055] (1) The microorganisms used for leaching are Ferroplasmaacidiphilum, Leptospirillum ferriphilum, Sulfobacillusacidophilus, and Ferroplasmathermophilum, which were passed through 45 The mixed culture acclimatized in the corresponding electroplating sludge system under the condition of ℃.

[0056] (2) The bioleaching process is carried out in an 800L stirred reactor with temperature control, 227.3kg of sludg...

Embodiment 3

[0070] The raw material used is electroplating sludge discharged from an electroplating factory in Xiangtan City, Hunan Province, and its chemical composition is shown in Table 9.

[0071] Table 9 Example 3 dry base electroplating sludge main chemical composition

[0072] the element

Cr

Ni

Zn

Cu

Fe

Na

Content %

0.92

0.38

10.42

1.56

10.40

0.65

[0073] A process for harmless disposal and resource utilization of electroplating sludge containing chromium, iron, nickel, copper and zinc, comprising the following steps:

[0074] (1) The microorganisms used for leaching, Ferroplasmaacidiphilum, Leptospirillum ferriphilum and Ferroplasmathermophilum, are passed through the corresponding electroplating sludge system at 50°C Mixed cultures acclimated in .

[0075] (2) The bioleaching process is carried out in a 500L stirred reactor with temperature control, 151.5kg of sludge is added, the moisture content of the sludg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com