Ultrasonic synergetic crystal growing fruit juice freezing and concentrating method and equipment thereof

A technology of freeze concentration and fruit juice, which is applied in the direction of food science, etc., to achieve the effect of less entrainment loss, less investment in equipment, and increased growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

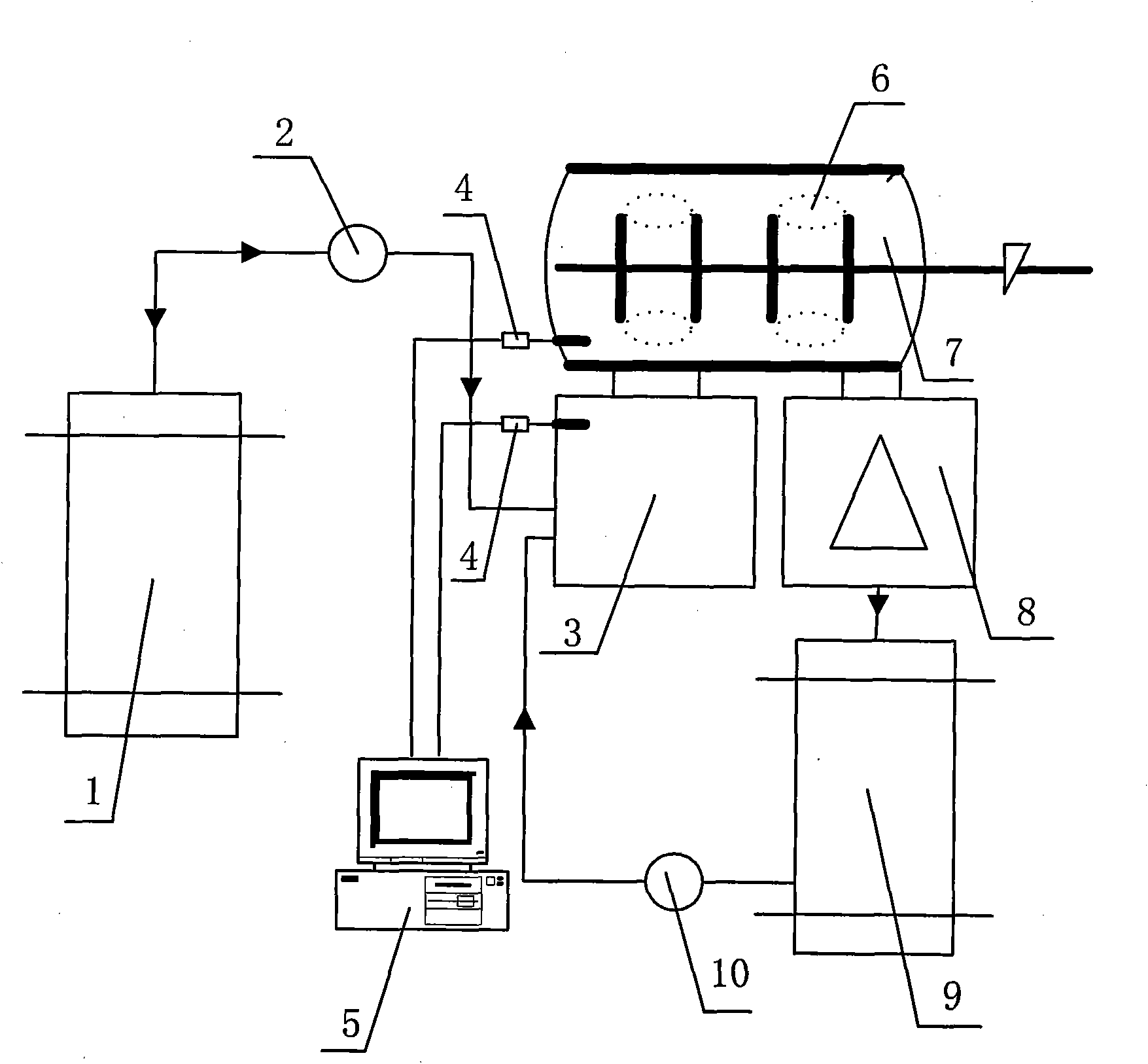

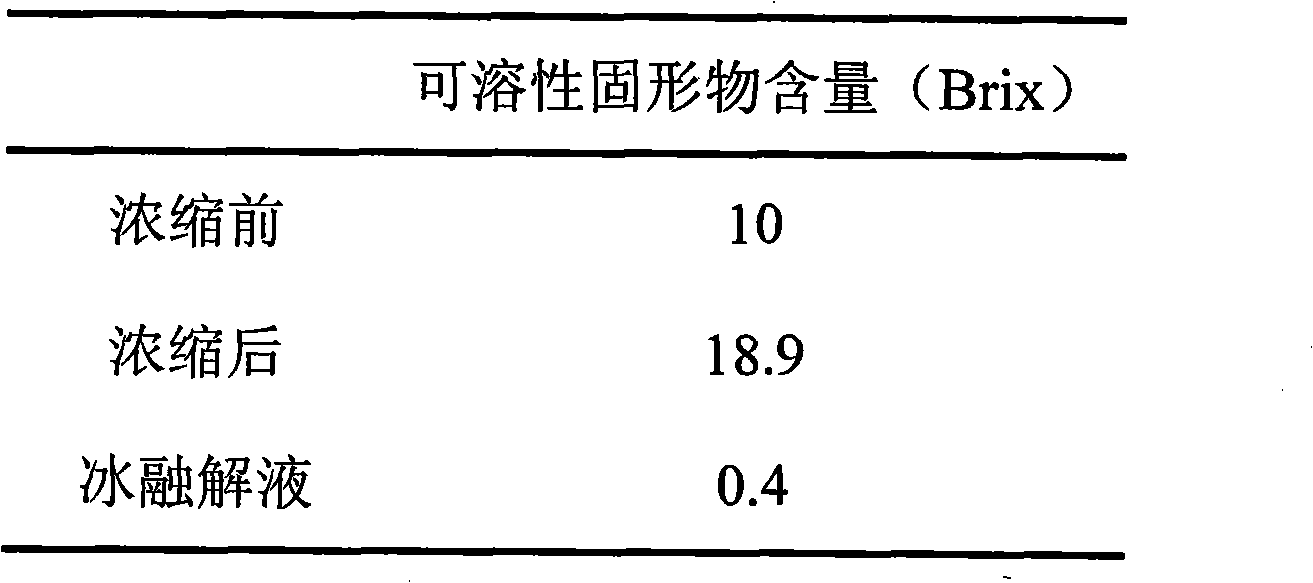

Embodiment 1

[0030] Using lychee juice as raw material, centrifuge at 3000r / min for 10min to obtain clarified juice: soluble solids content = 10°Brix; μ = 3.6mpas; turbidity = 6.4NTU. equipment connection such as figure 1 shown. The fruit juice to be treated is pumped from the fruit juice storage 1 into the scraped surface heat exchanger 3 through the centrifugal pump 2, and then enters the crystal growth tank 7 through the channel connected to the lower end of the crystal growth tank. The total volume of the crystal growth tank is 30L. In order to prevent the volume from expanding after the water forms ice crystals, the volume of the working fluid is 25L. After 25L of working fluid is completely pumped in, the scraper heat exchanger 3 is turned on for pre-cooling, the scraper speed is 30rpm, and the cooling power is 1kW. The probe built in the heat exchanger displays the temperature change of the fruit juice on the computer 5 through the temperature recorder 4 . When the temperature dr...

Embodiment 2

[0034] Using apple juice as raw material, centrifuge at 4000r / min for 10min to obtain clarified juice: soluble solids content = 20°Brix; μ = 4.4mpas; turbidity = 11NTU. The equipment and operation process are the same as in Example 1. The total volume of the crystal growth tank is 30L. In order to prevent the volume from expanding after the water forms ice crystals, the volume of the working fluid is 25L. The fruit juice to be treated is pumped from the fruit juice storage 1 into the scraped surface heat exchanger 3 through the centrifugal pump 2, and then enters the crystal growth tank 7 through the channel connected to the lower end of the crystal growth tank. After 25L of working fluid is completely pumped in, the scraper heat exchanger 3 is turned on for pre-cooling, the scraper speed is 40rpm, and the cooling power is 1.5kW. Pre-cool to the freezing point temperature of the fruit juice -2°C, turn on the crystal growth tank stirring device and the ultrasonic field generati...

Embodiment 3

[0038] Using high-concentration orange juice as raw material, centrifuge at 5000r / min for 15min to obtain clarified juice: soluble solid content = 40°Brix; μ = 10mpas; turbidity = 15NTU. The equipment and operation process are the same as above. The total volume of the crystal growth tank is 30L. In order to prevent the volume from expanding after the water forms ice crystals, the volume of the working fluid is 25L. The fruit juice to be treated is pumped from the fruit juice storage 1 into the scraped surface heat exchanger 3 through the centrifugal pump 2, and then enters the crystal growth tank 7 through the channel connected to the lower end of the crystal growth tank. After 25L of working fluid is completely pumped in, the scraper heat exchanger 3 is turned on for pre-cooling, the scraper speed is 50rpm, and the cooling power is 2kW. Pre-cool to the freezing point temperature of the fruit juice -8.9°C, turn on the crystal growth tank stirring device and the ultrasonic fie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com