Method for removing heat-stable salt in flue gas desulfurization solution by normal-pressure ion exchanger

An ion exchanger, a technology of thermally stable salts, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., to achieve high desalination efficiency, low entrainment loss, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, the method for removing thermally stable salts in the flue gas desulfurization solution by the atmospheric pressure ion exchanger of the present invention will be described in conjunction with exemplary embodiments.

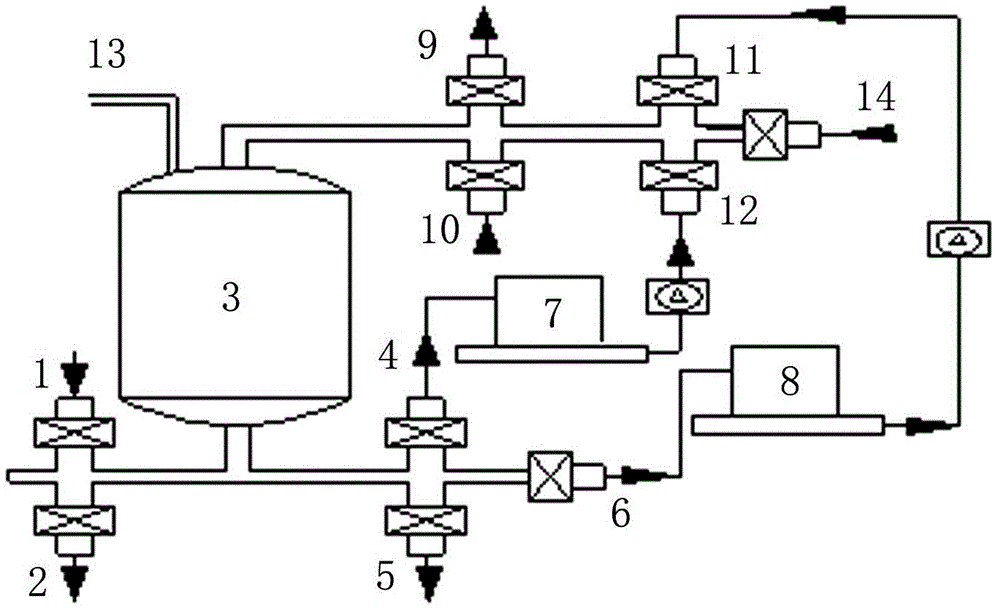

[0026] In an exemplary embodiment of the present invention, the flue gas desulfurization solution to be treated is produced by a flue gas desulfurization system comprising an absorption tower and a desorption tower containing SO 4 2- and Cl - The desulfurization solution, the method for removing thermally stable salts in the flue gas desulfurization solution by an atmospheric ion exchanger includes the following steps in sequence: A. Let the flue gas desulfurization solution pass through the ion exchanger in a manner of going in and out from the bottom to remove the flue gas SO in gas desulfurization solution 4 2- and Cl -Waiting for thermally stable salts to obtain a purified flue gas desulfurization solution; B. Venting the ion exchanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com