Patents

Literature

35results about How to "Improve threshing speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

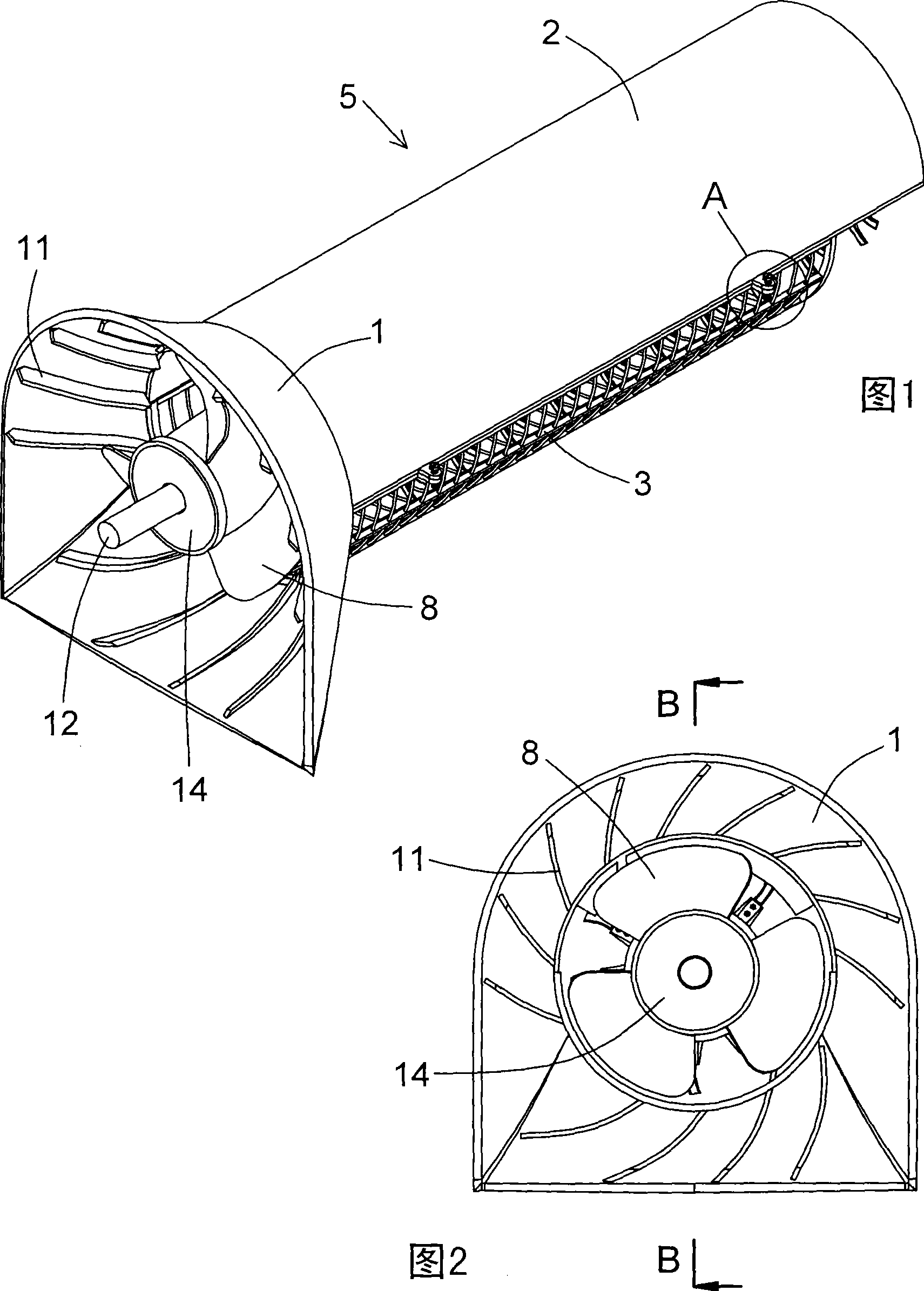

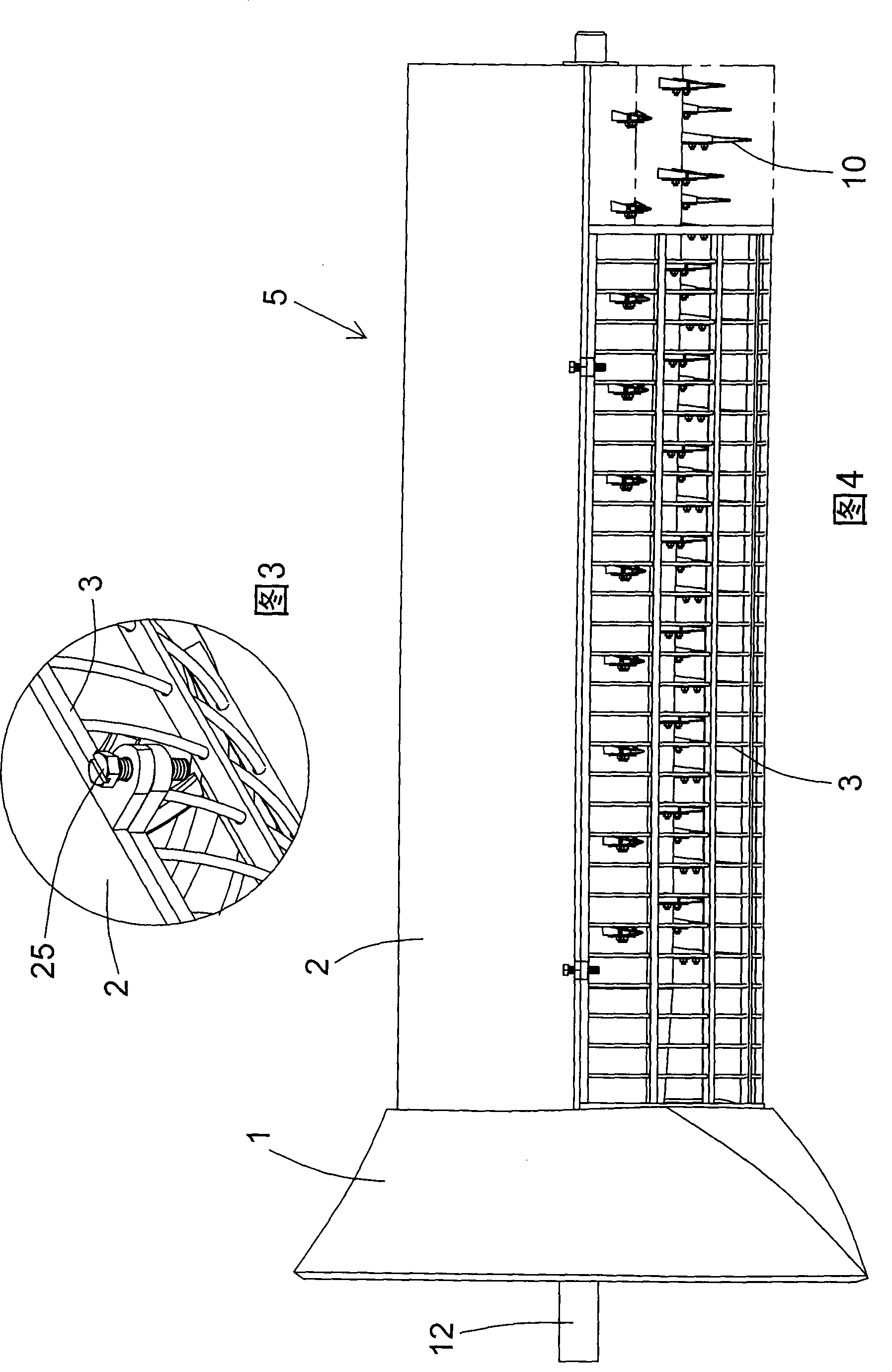

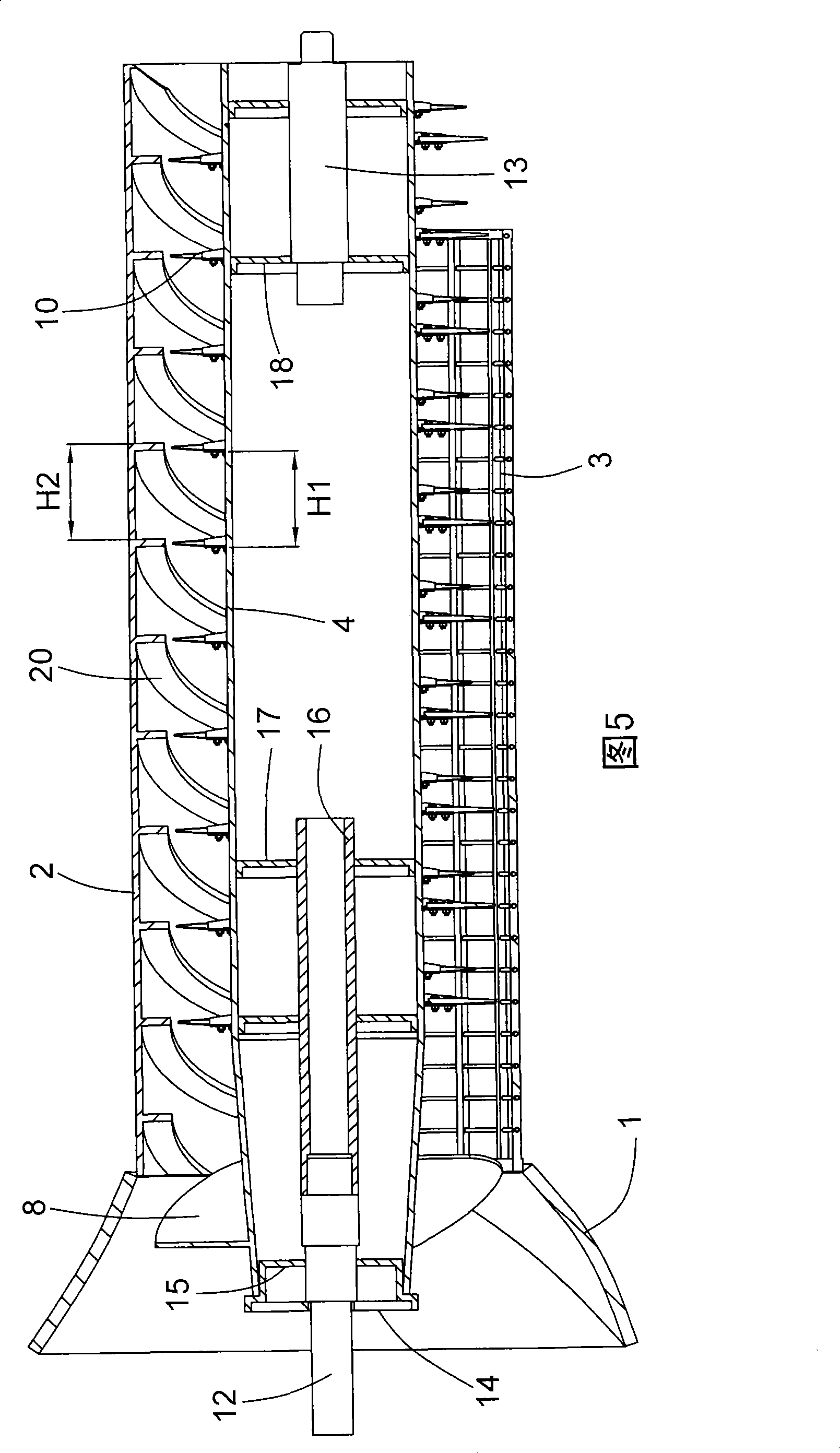

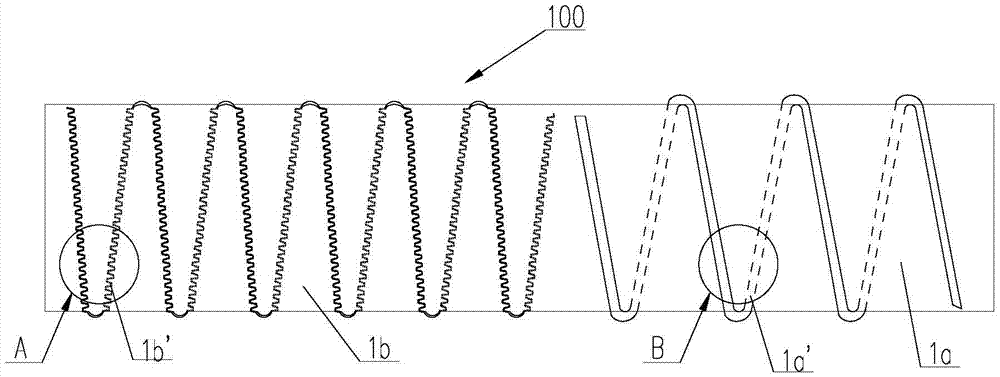

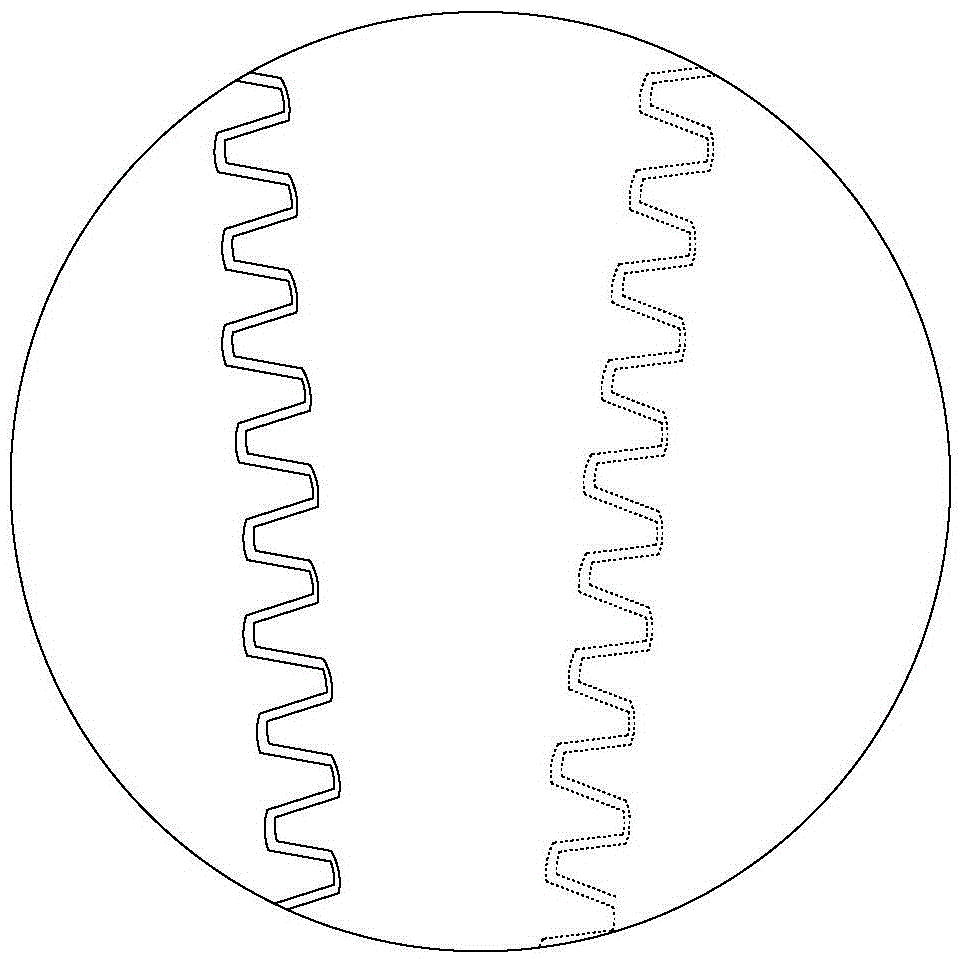

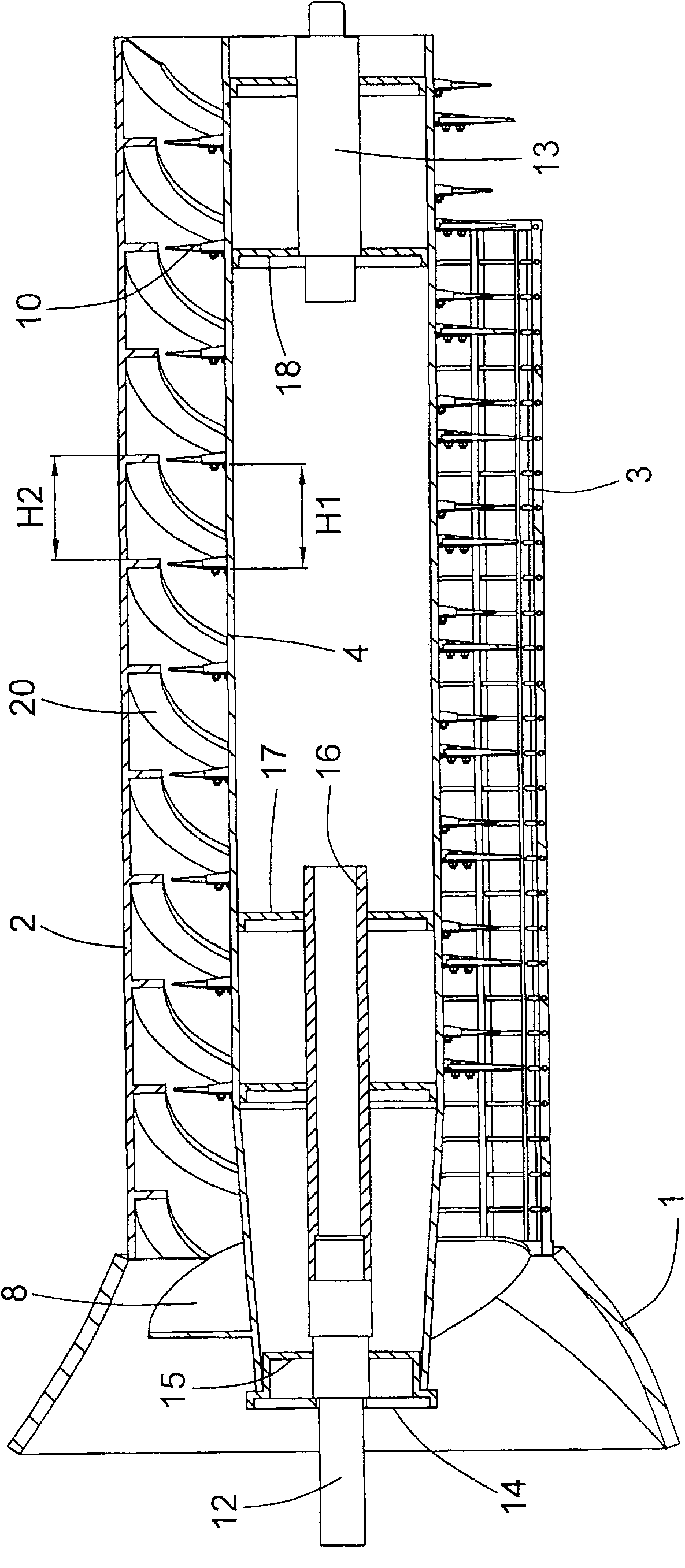

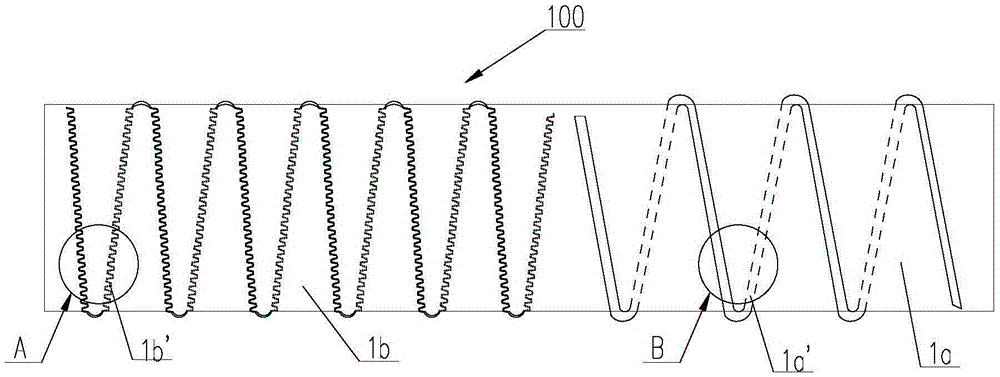

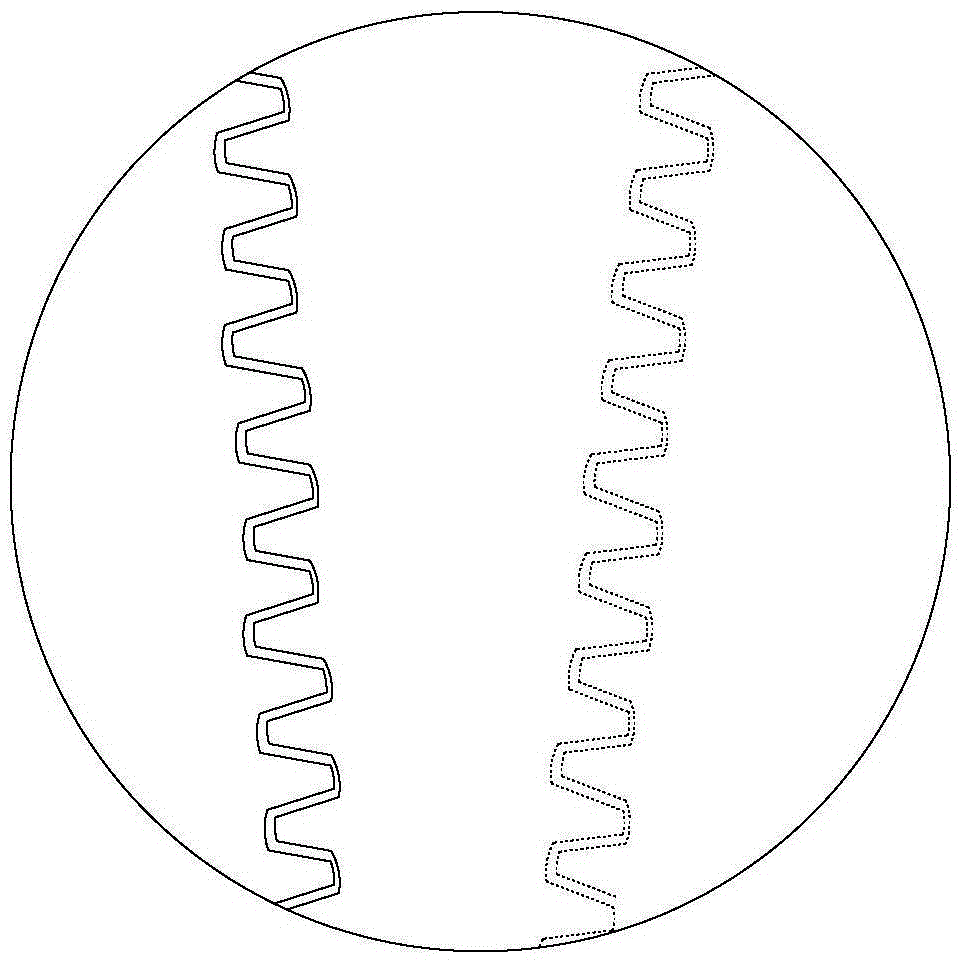

Grain threshing separation device

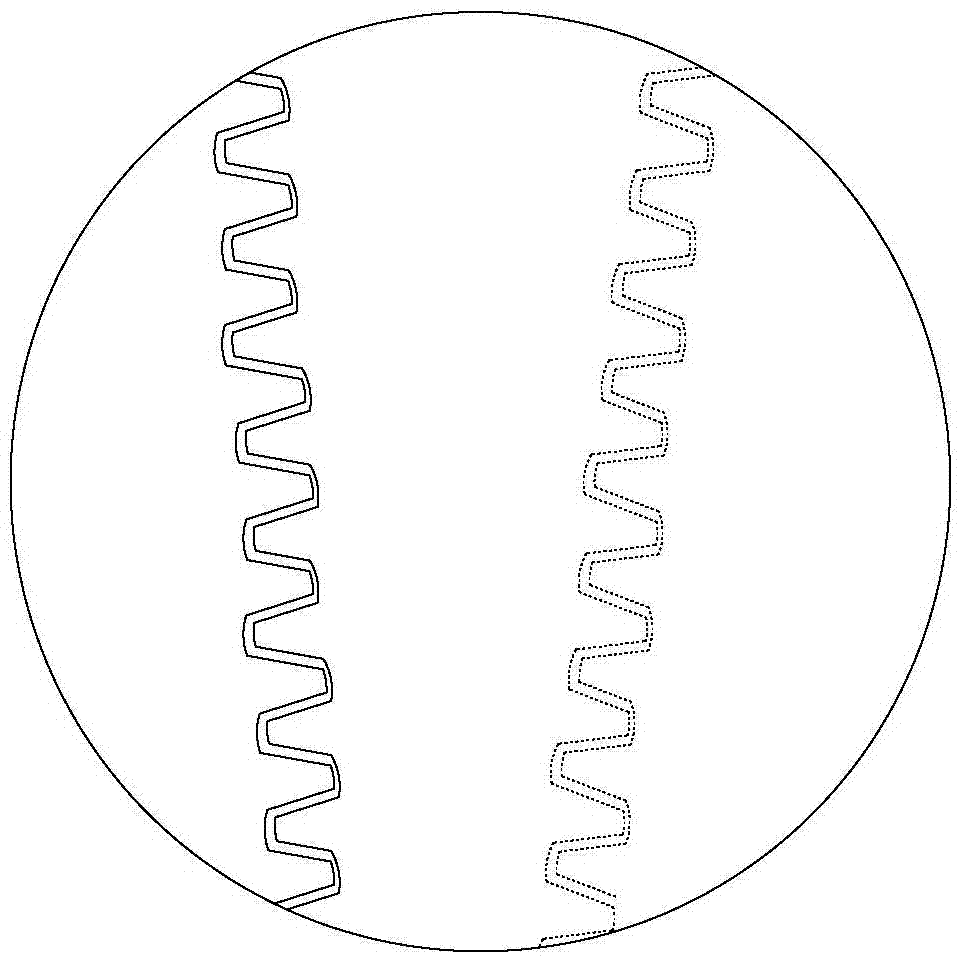

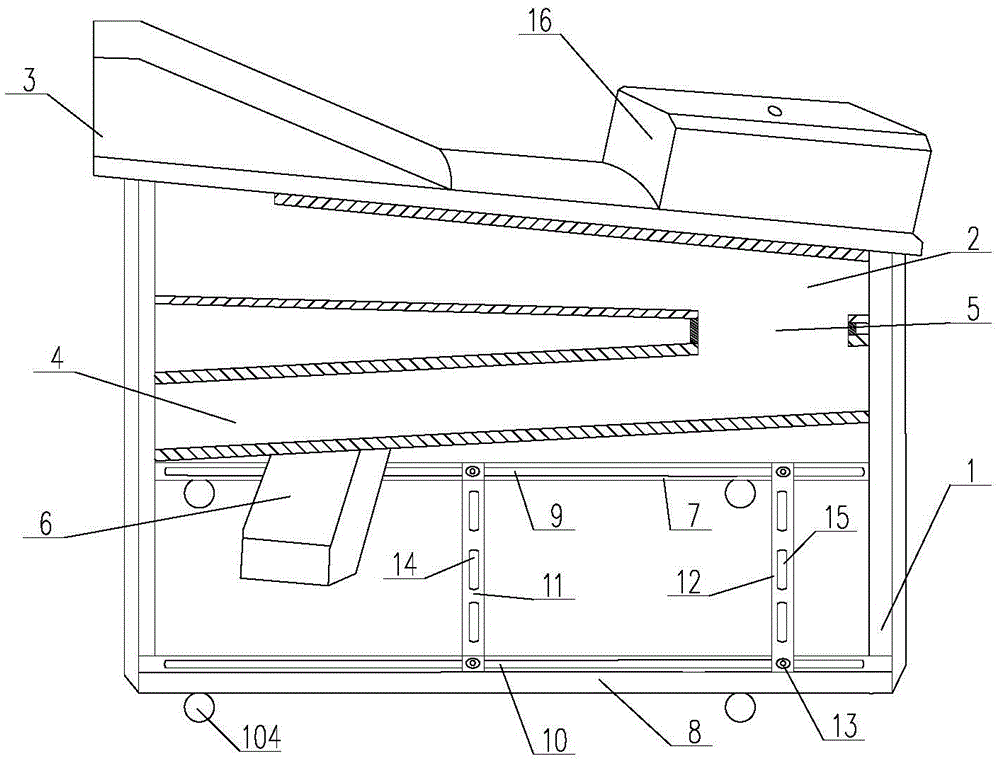

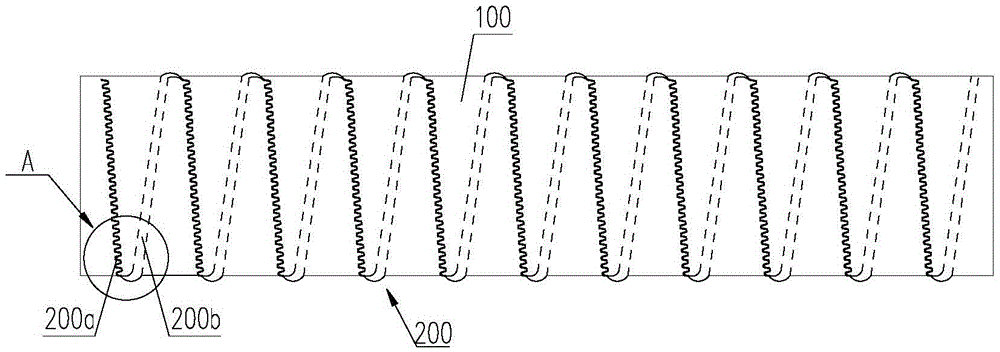

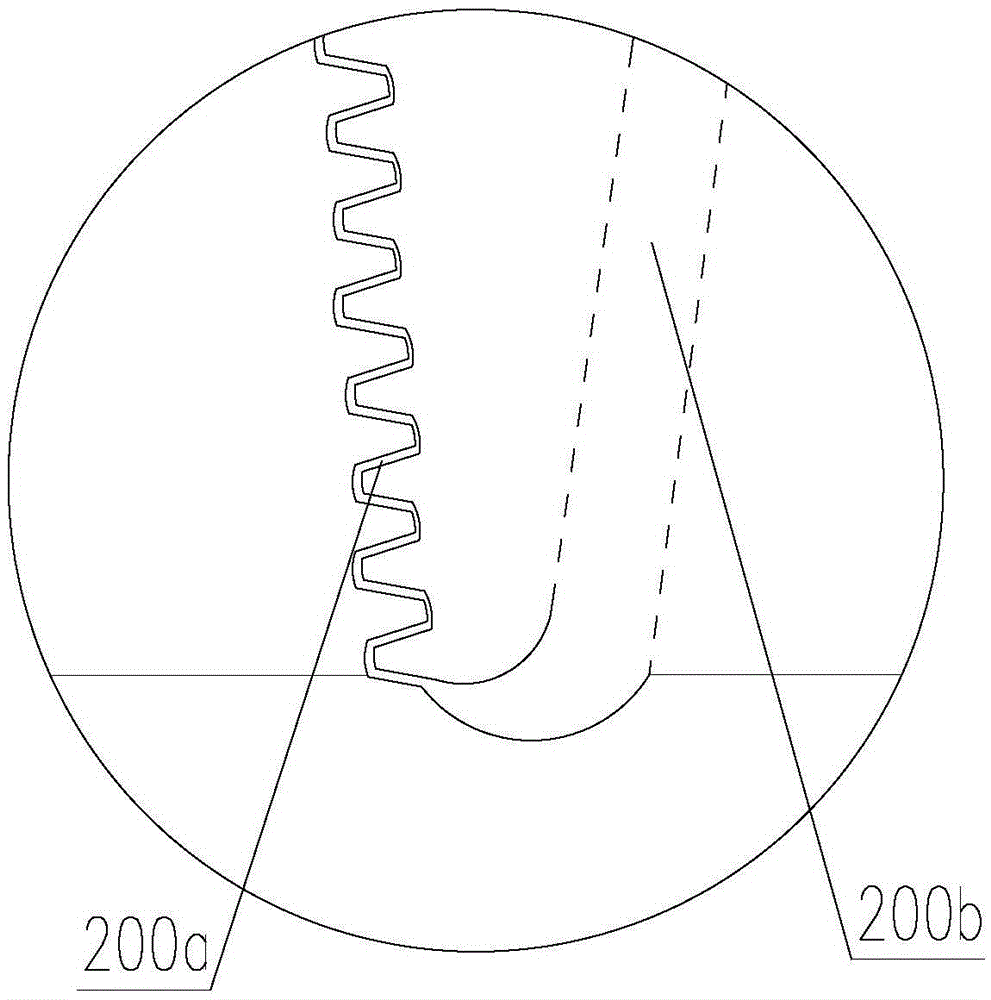

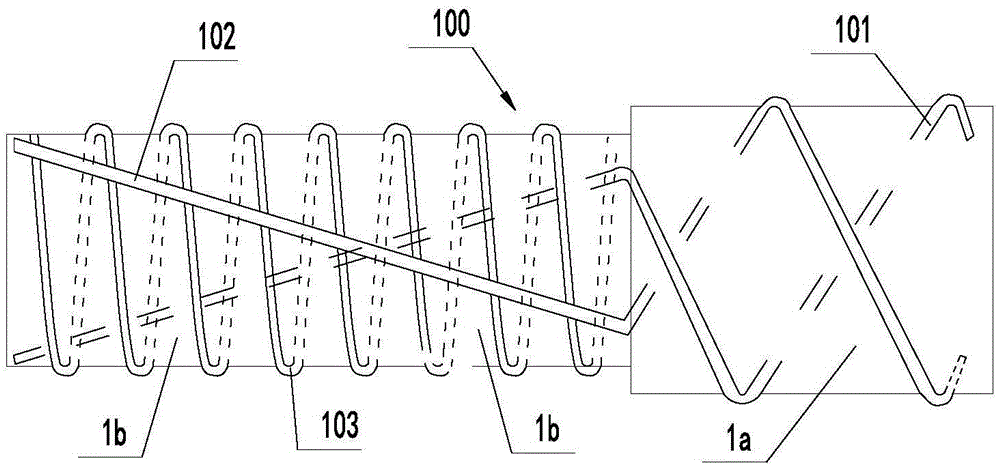

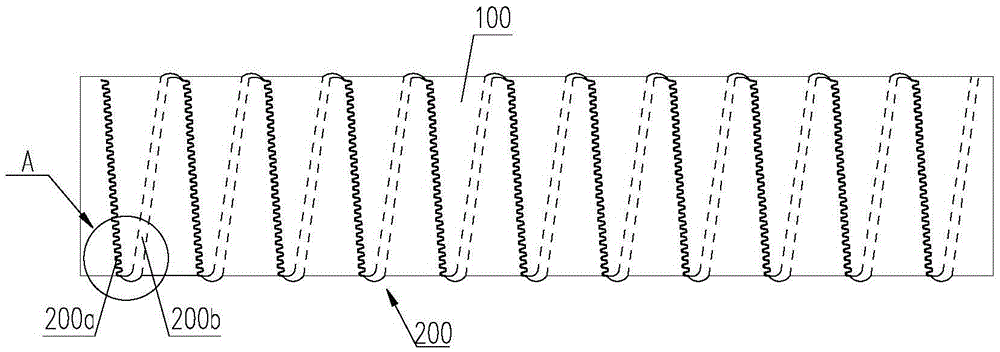

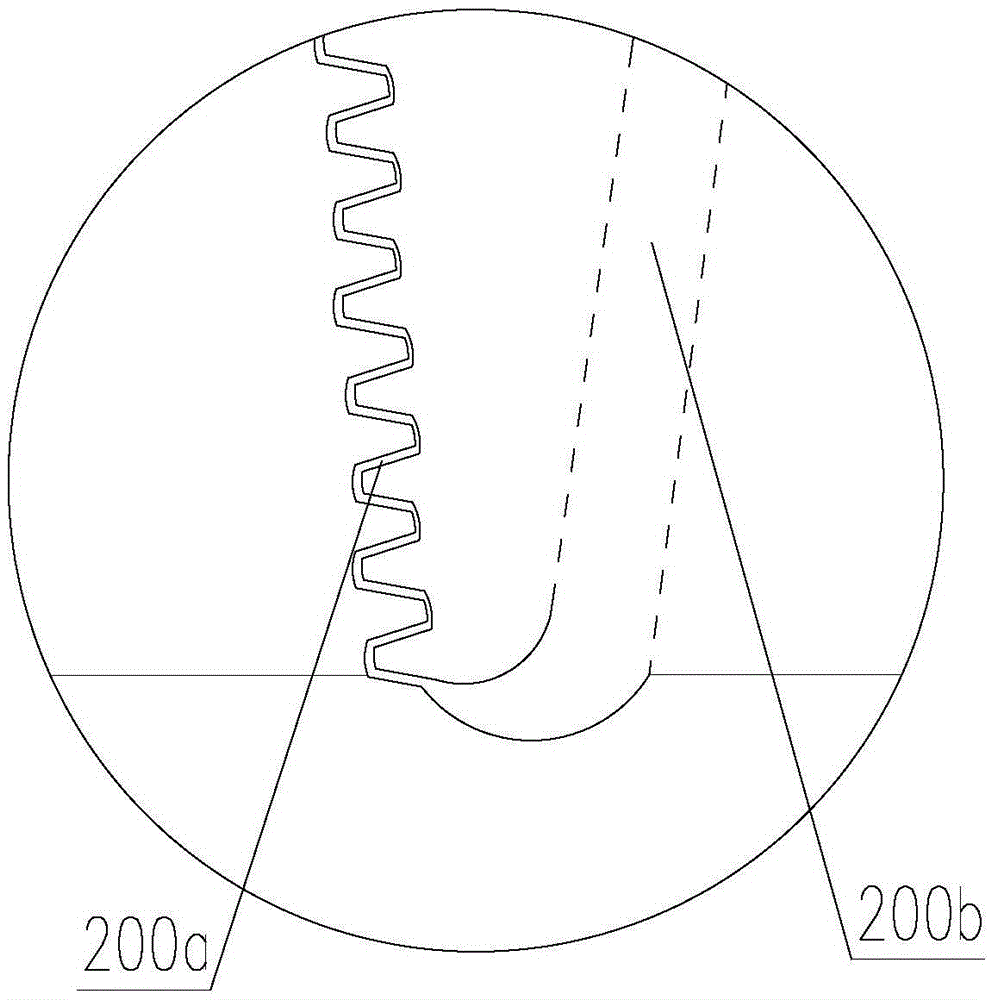

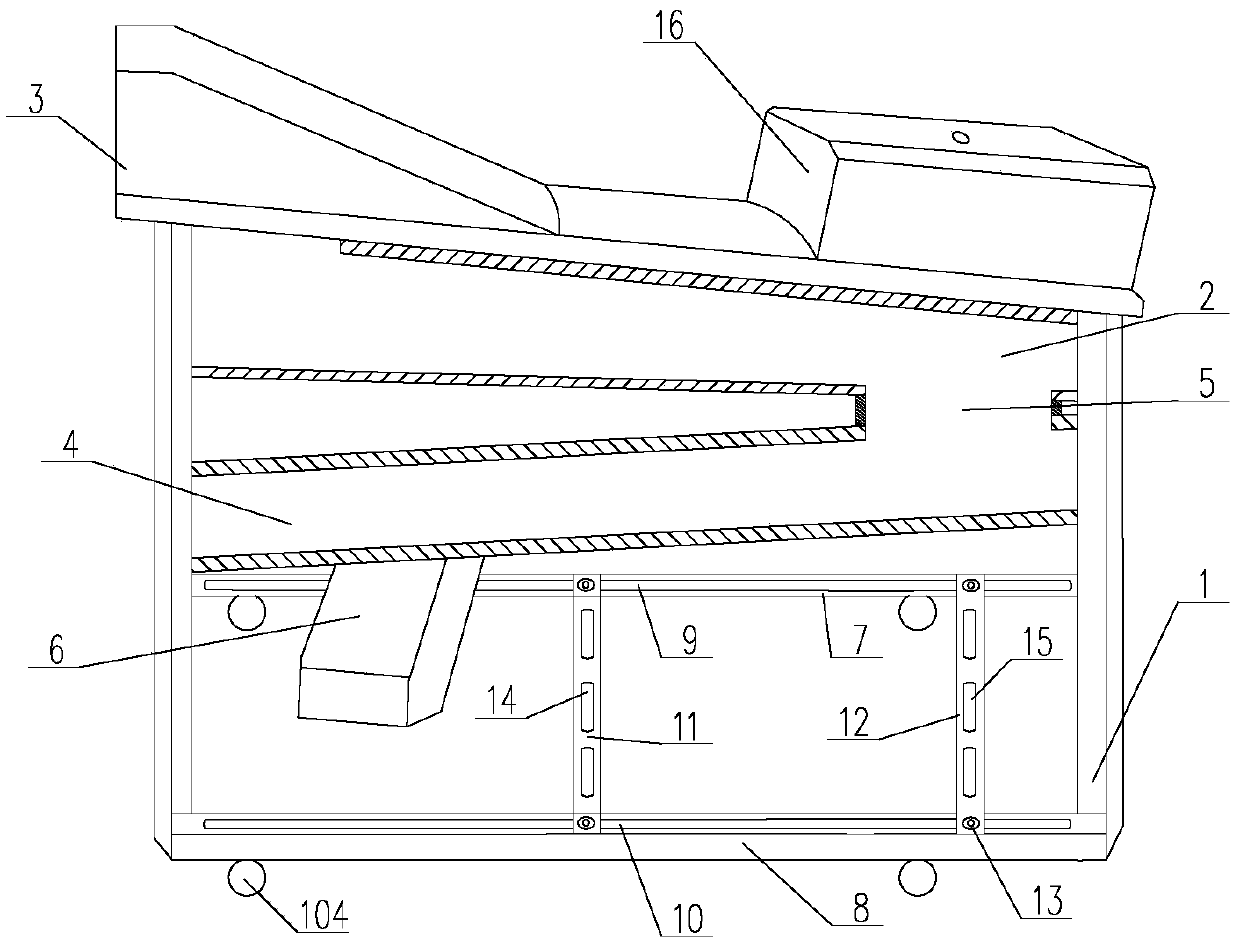

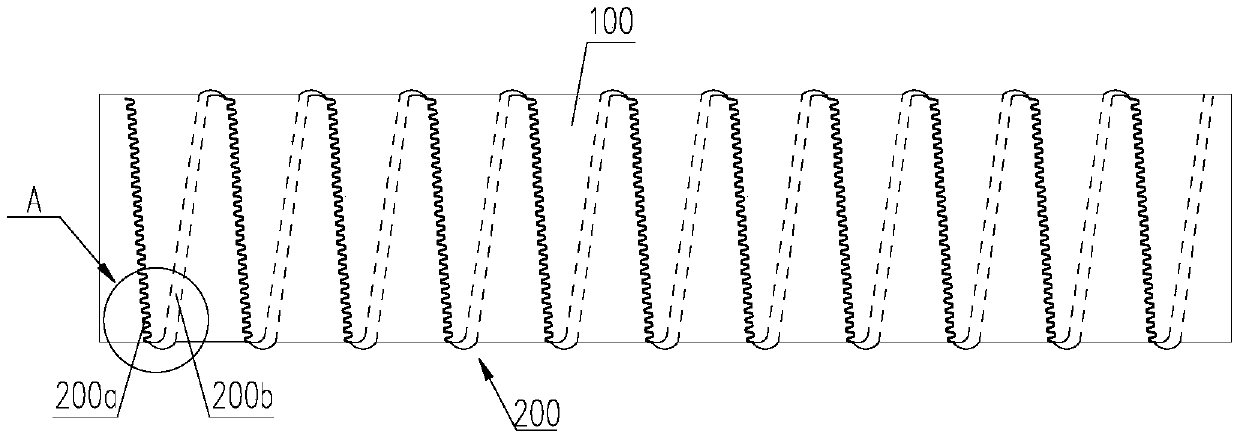

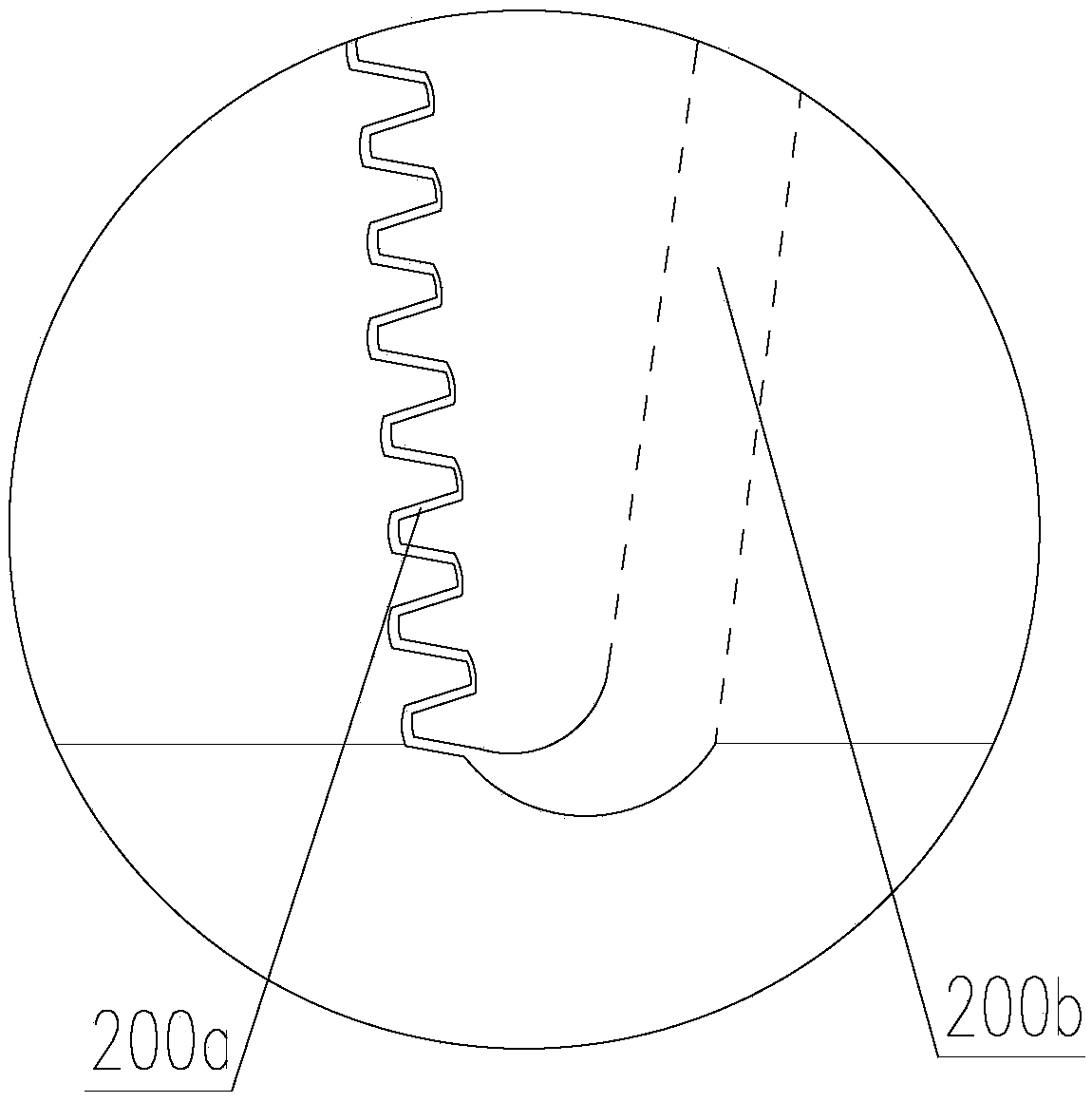

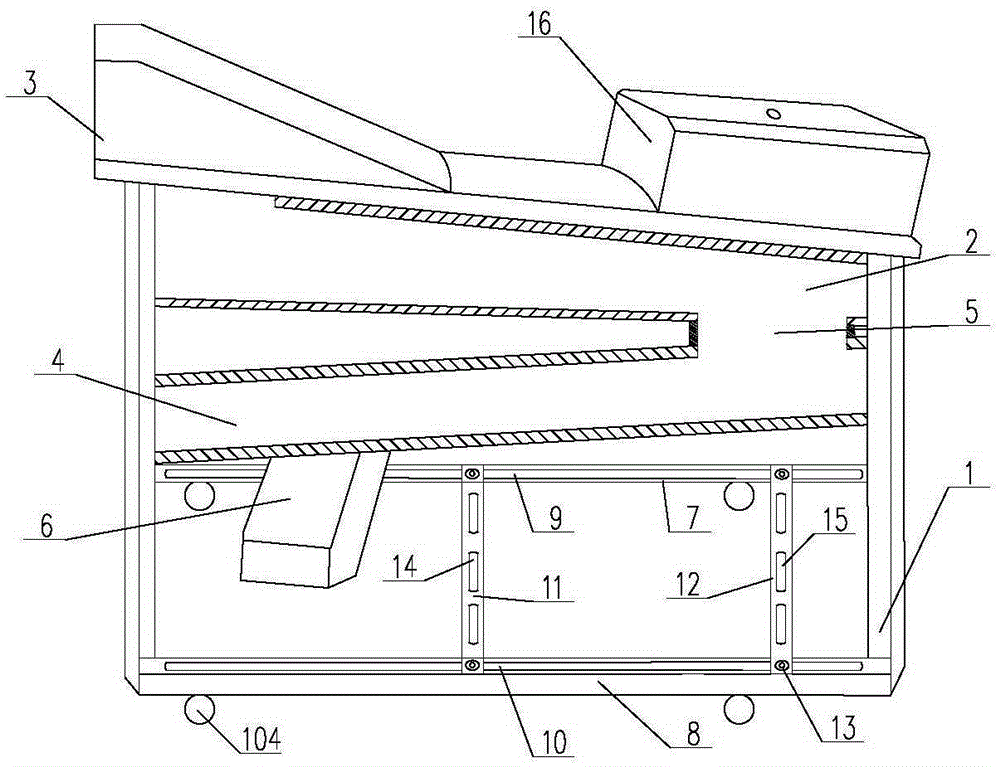

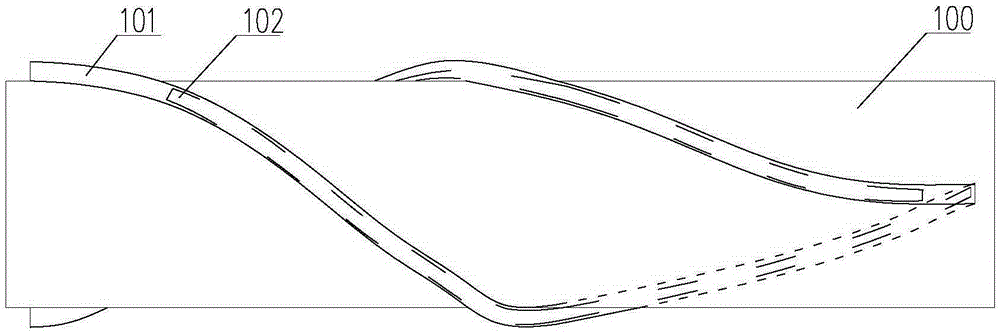

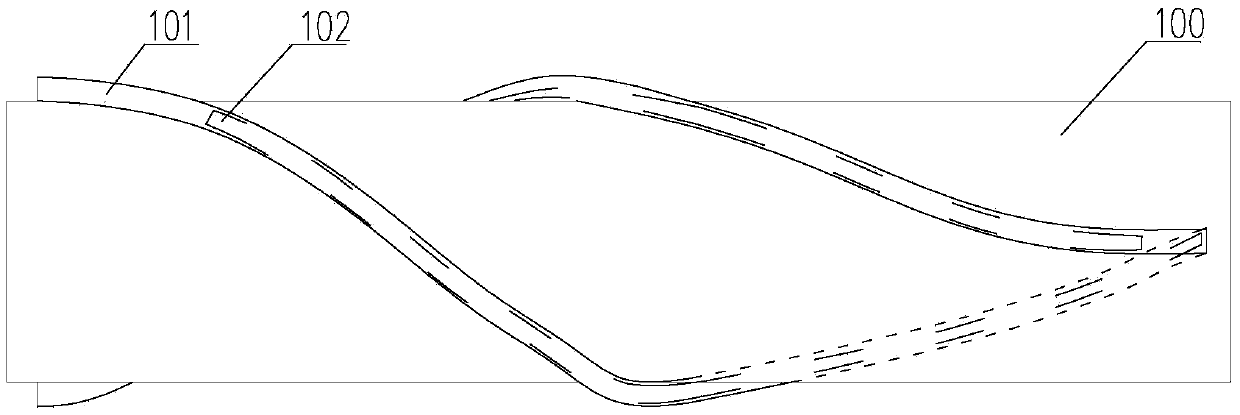

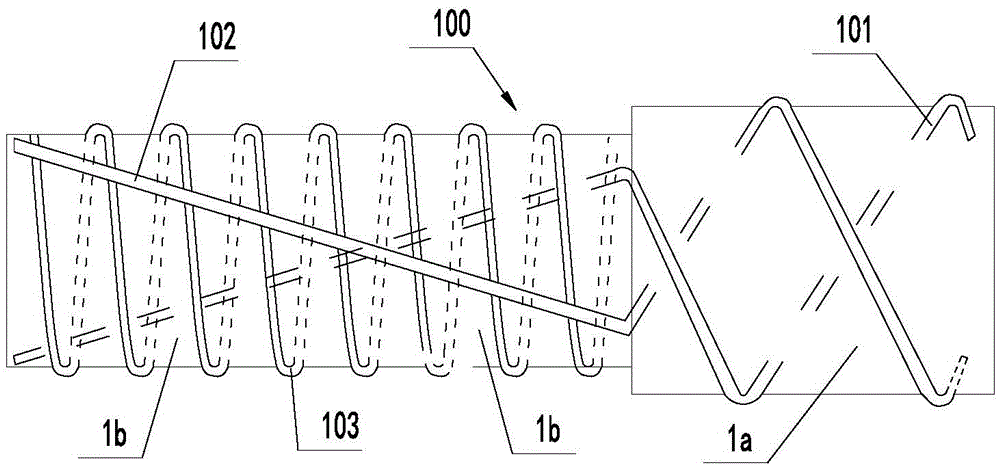

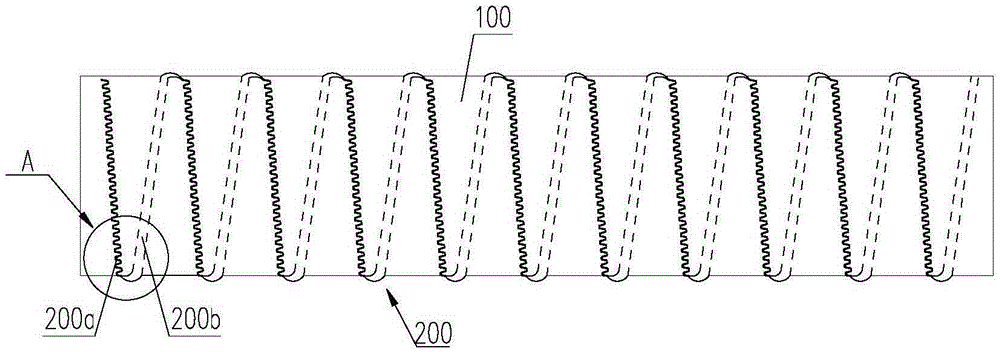

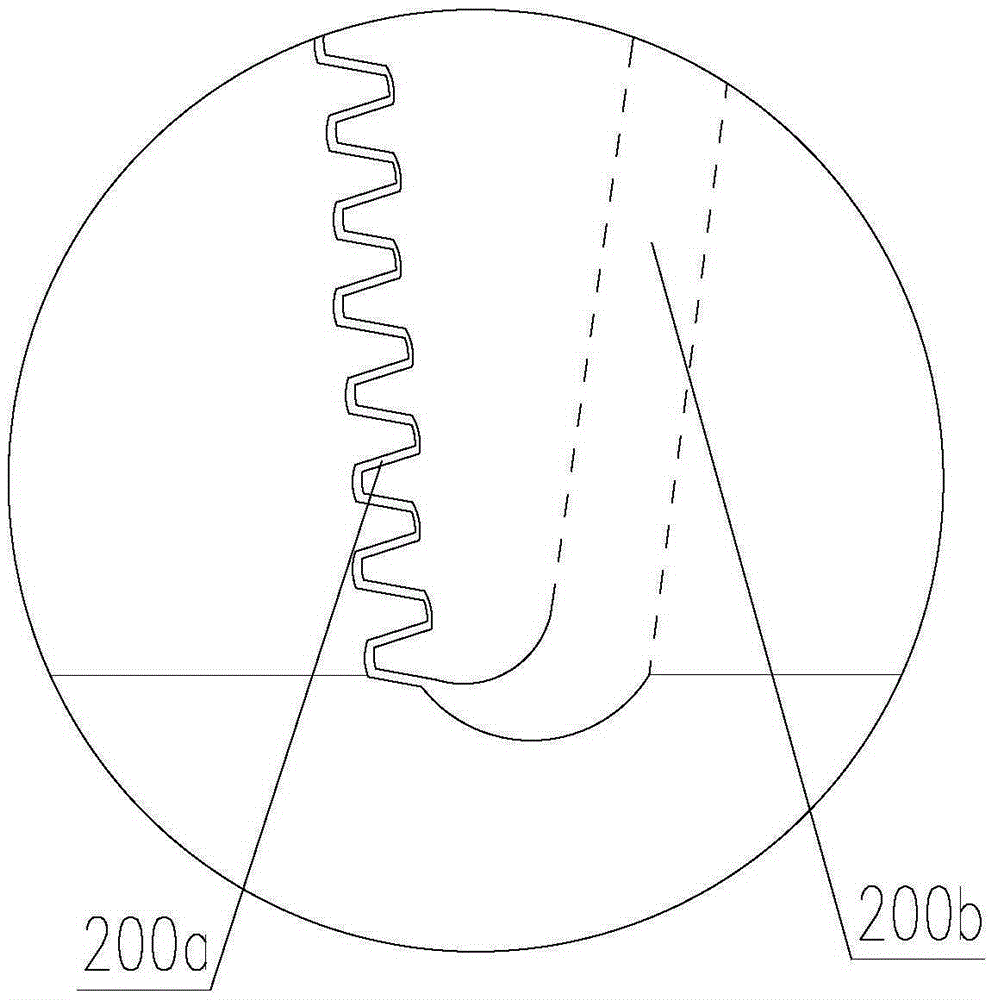

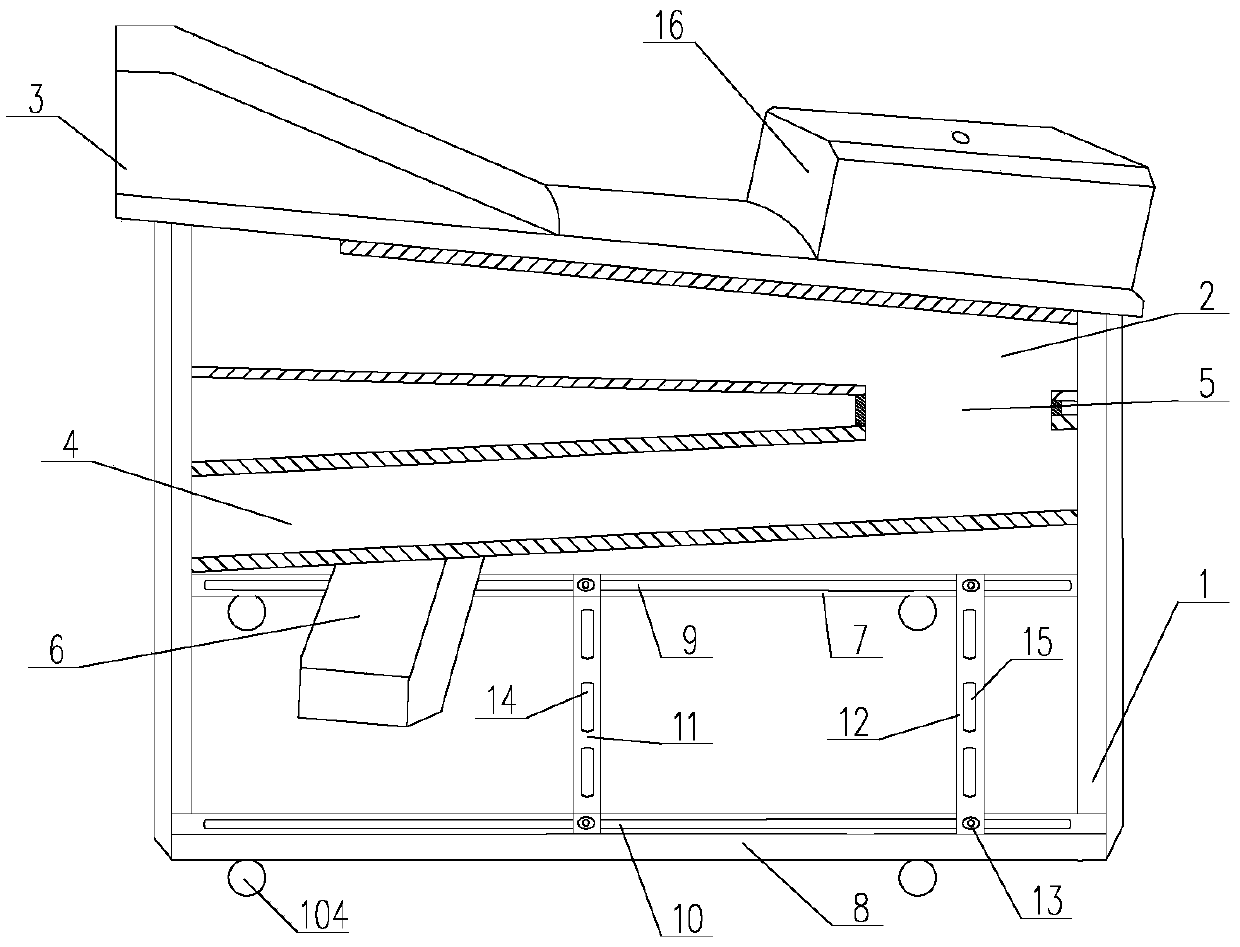

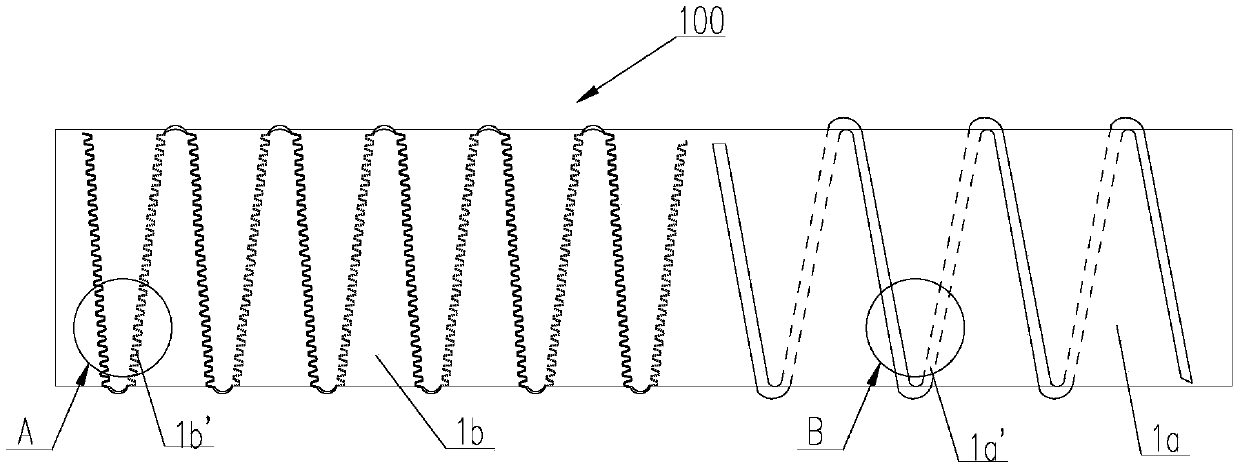

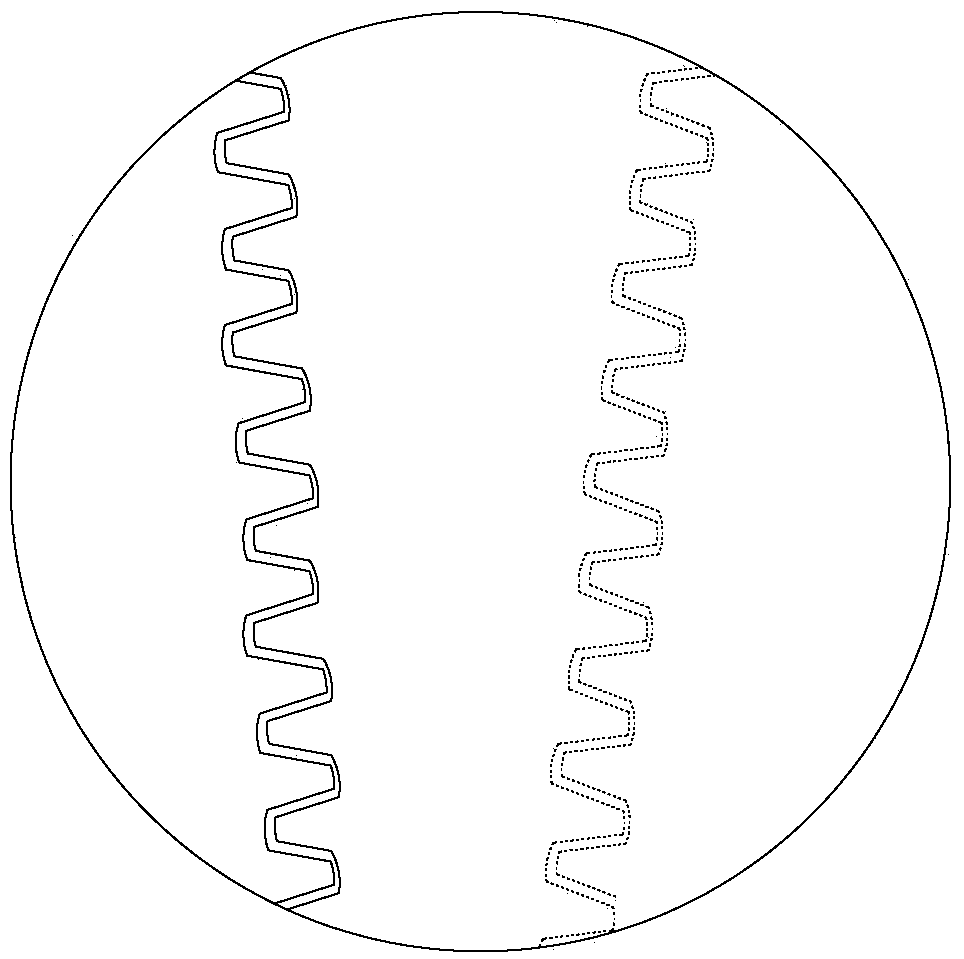

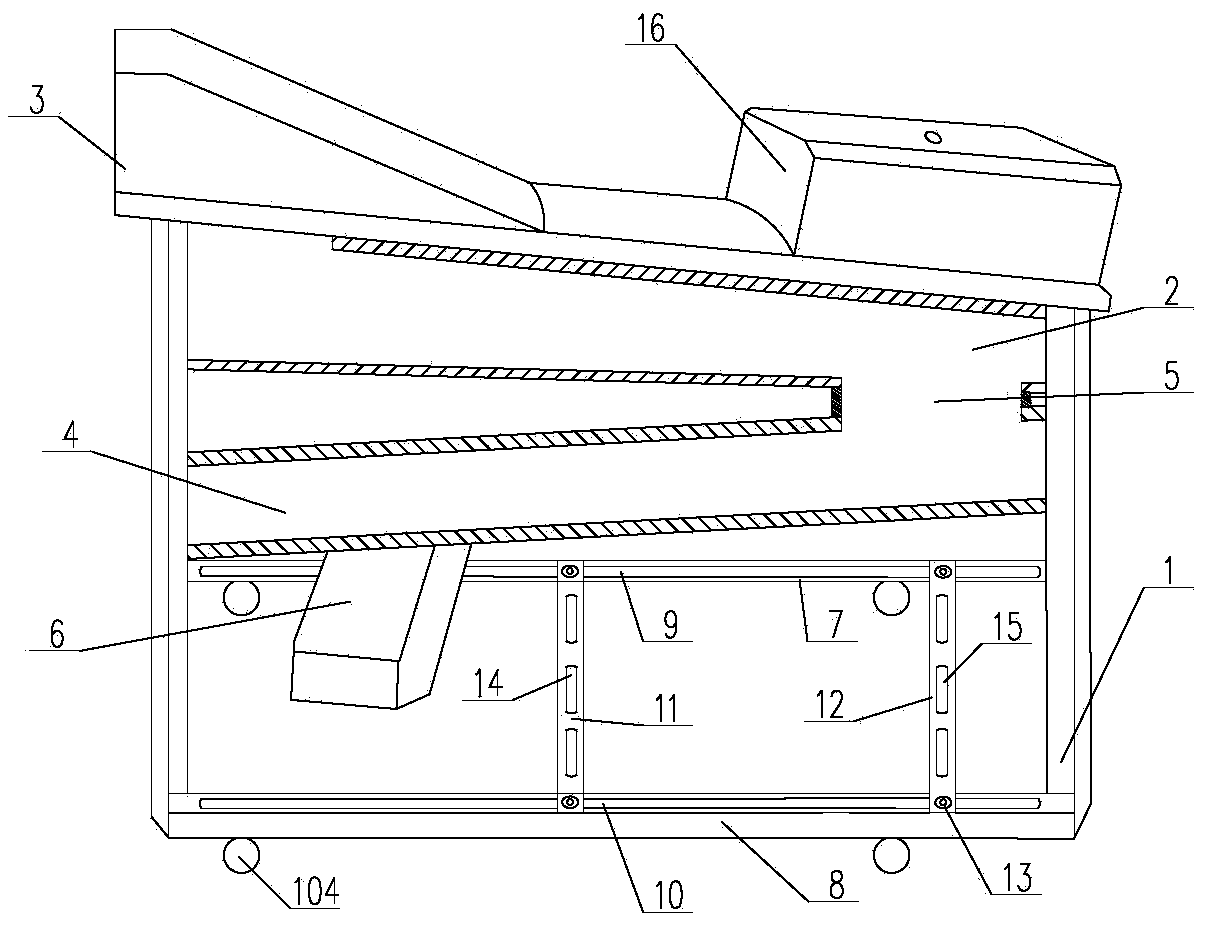

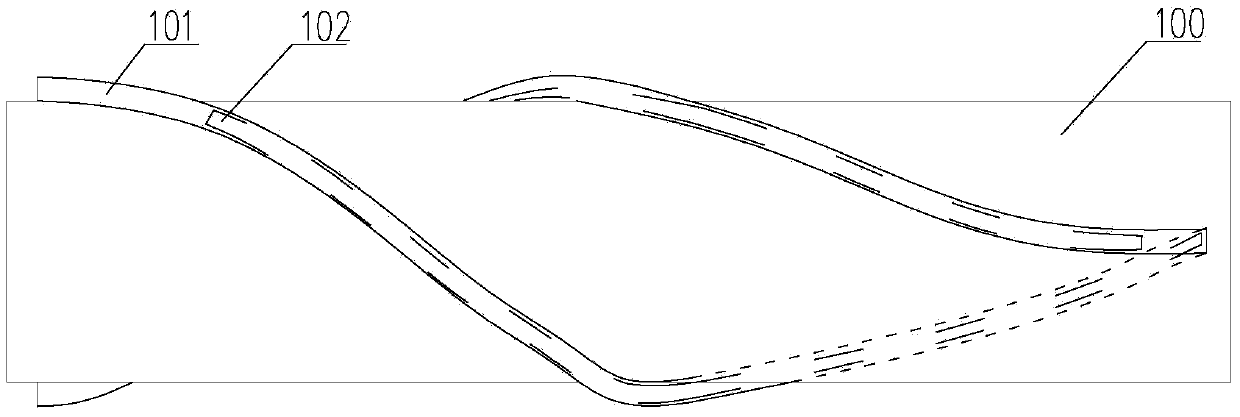

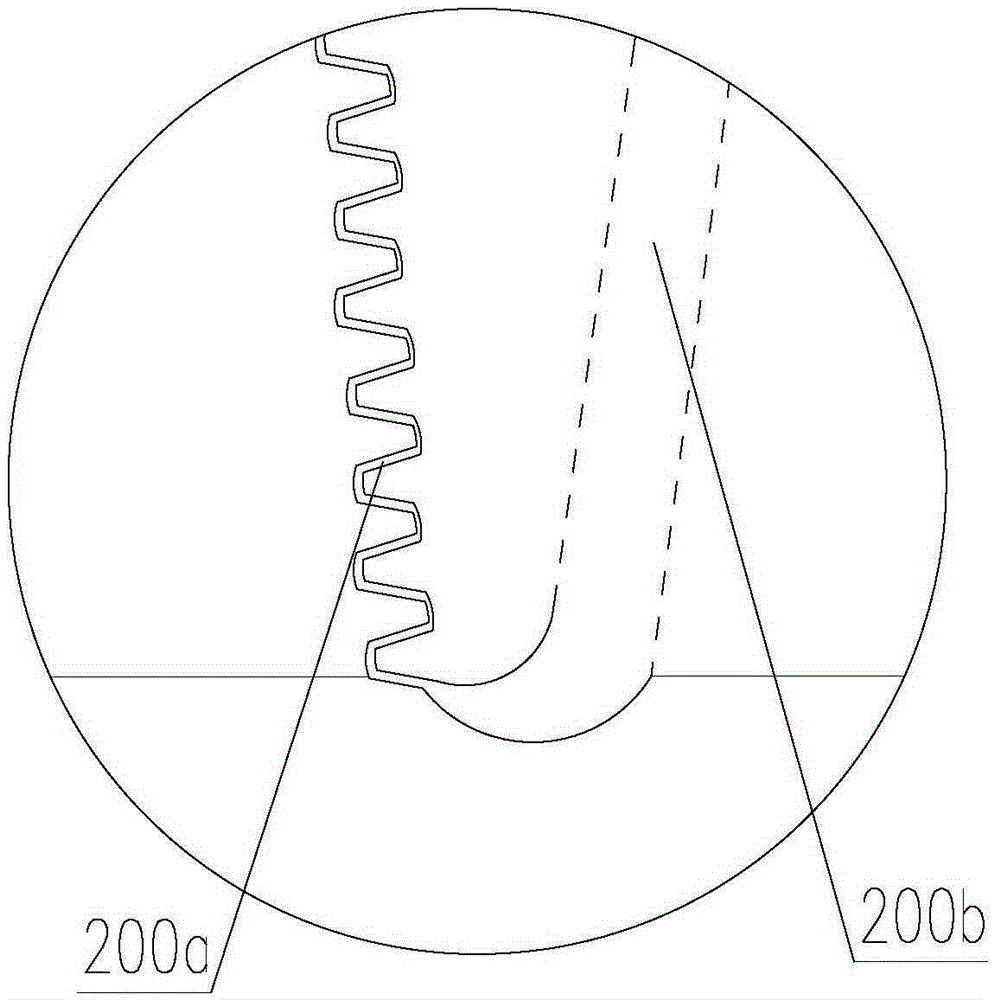

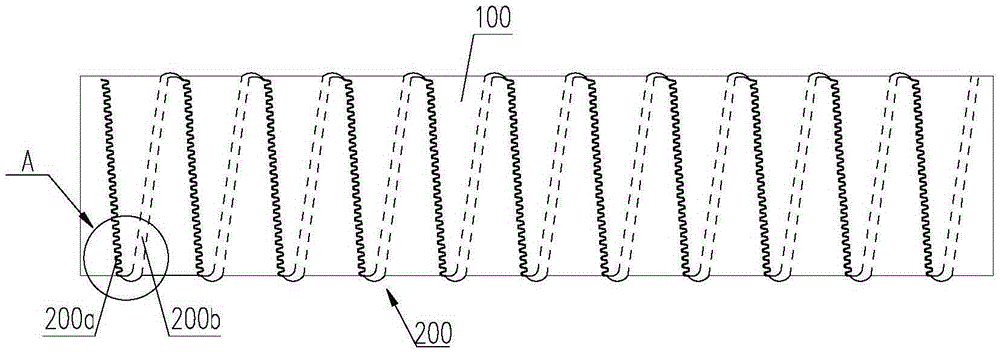

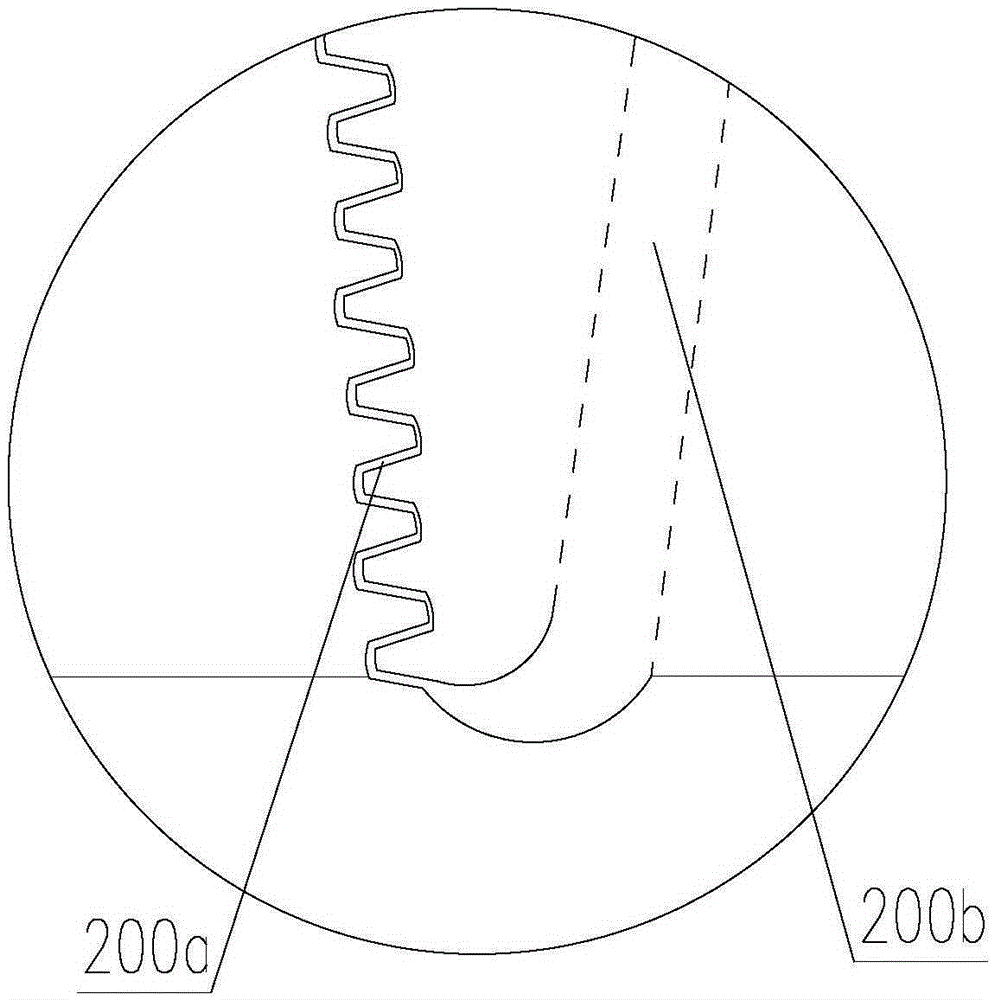

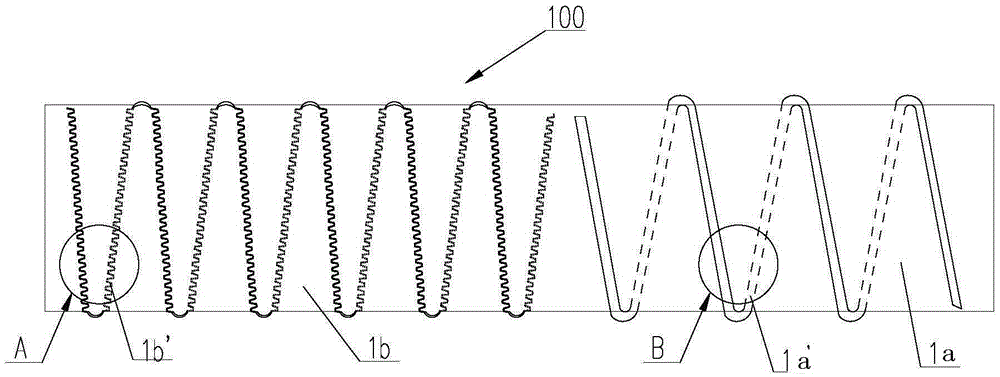

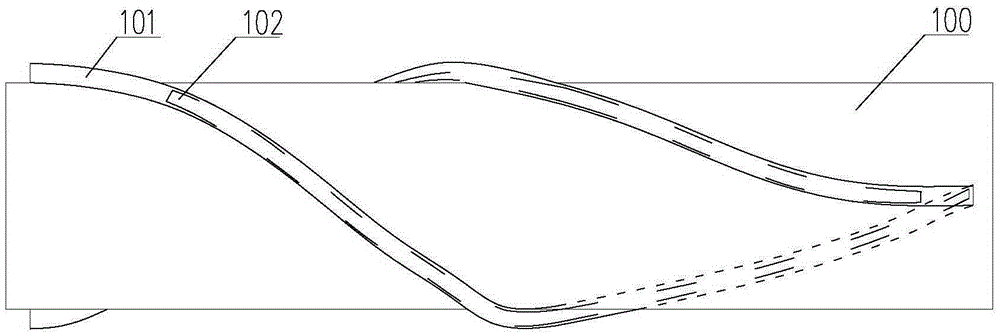

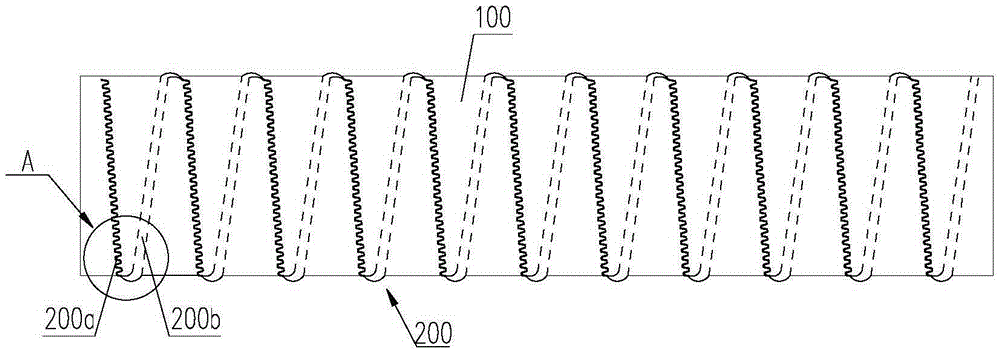

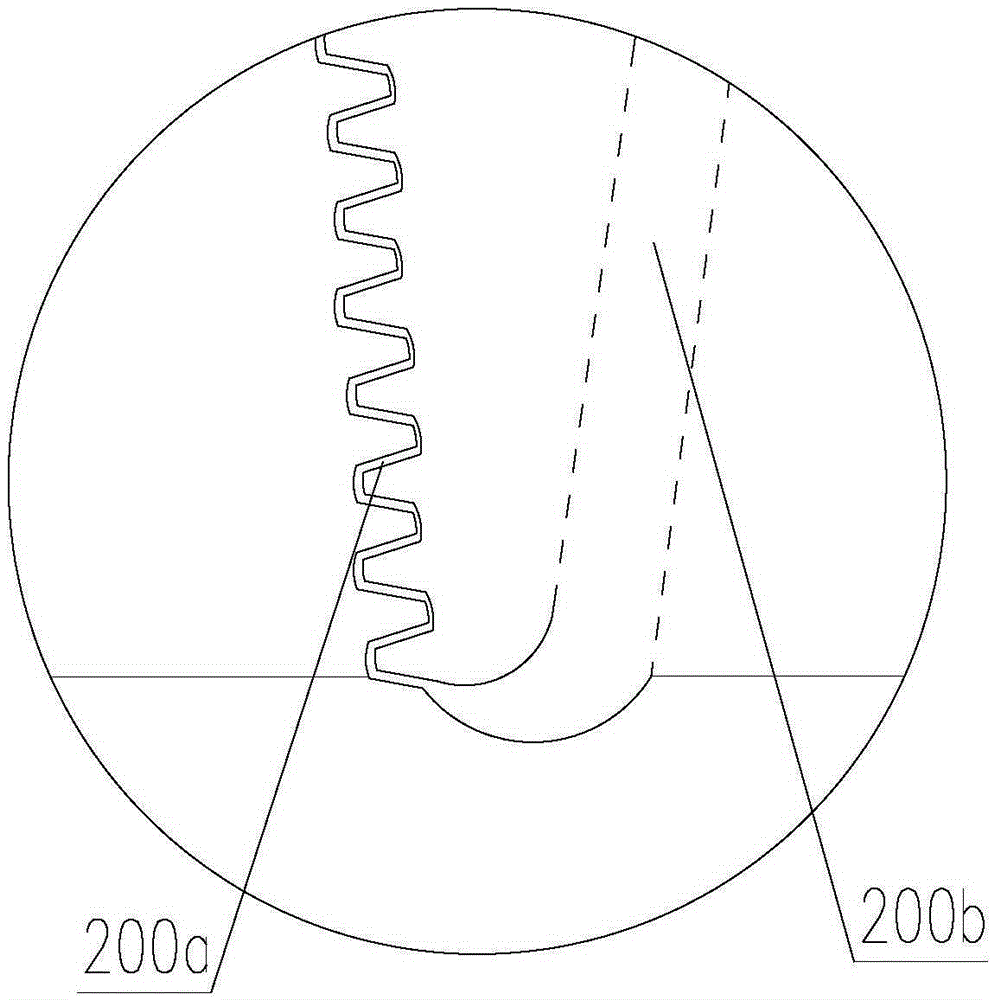

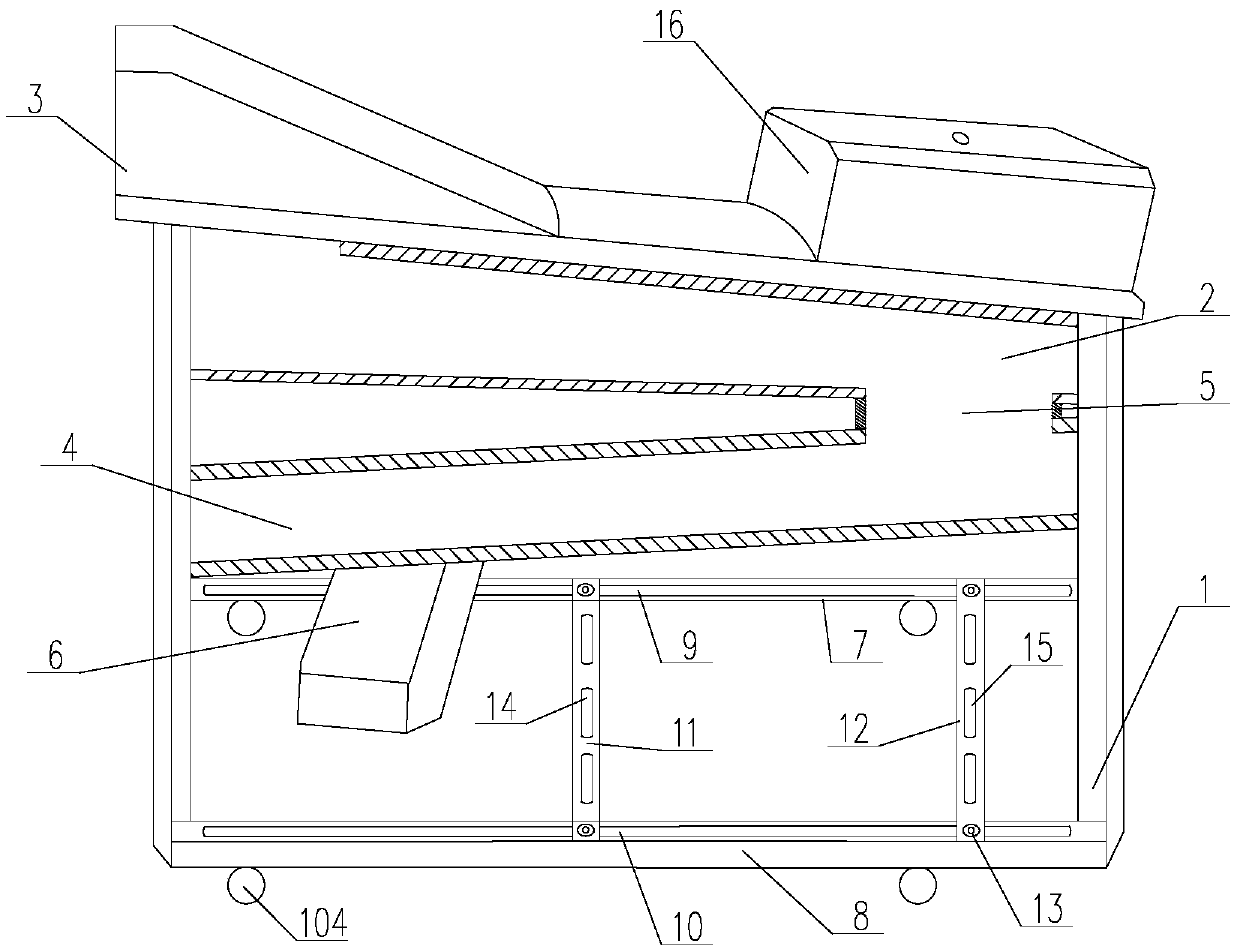

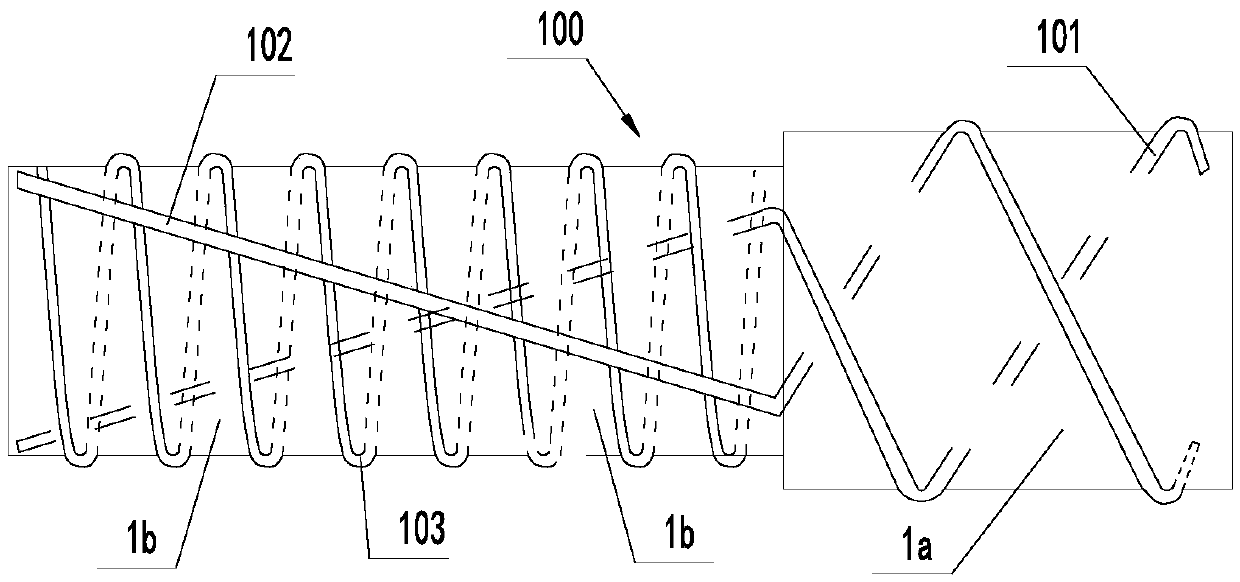

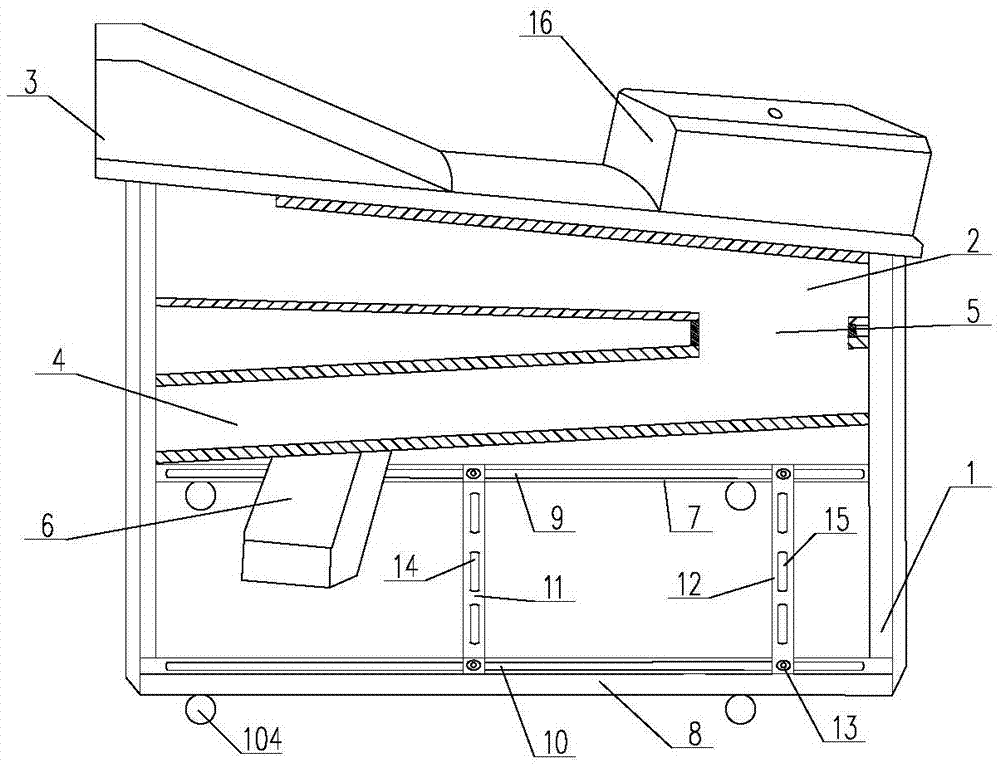

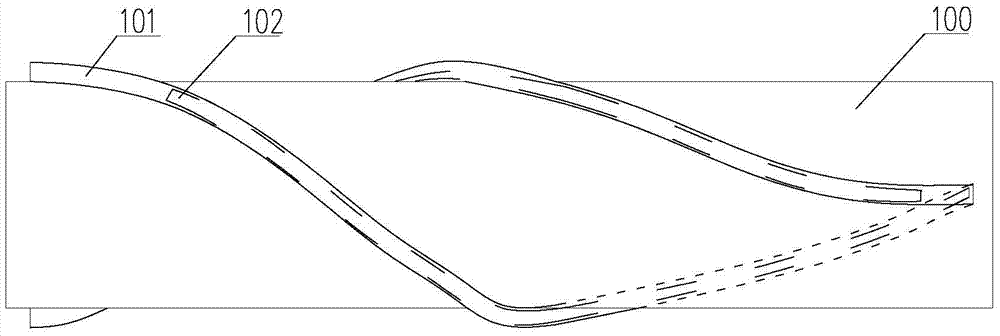

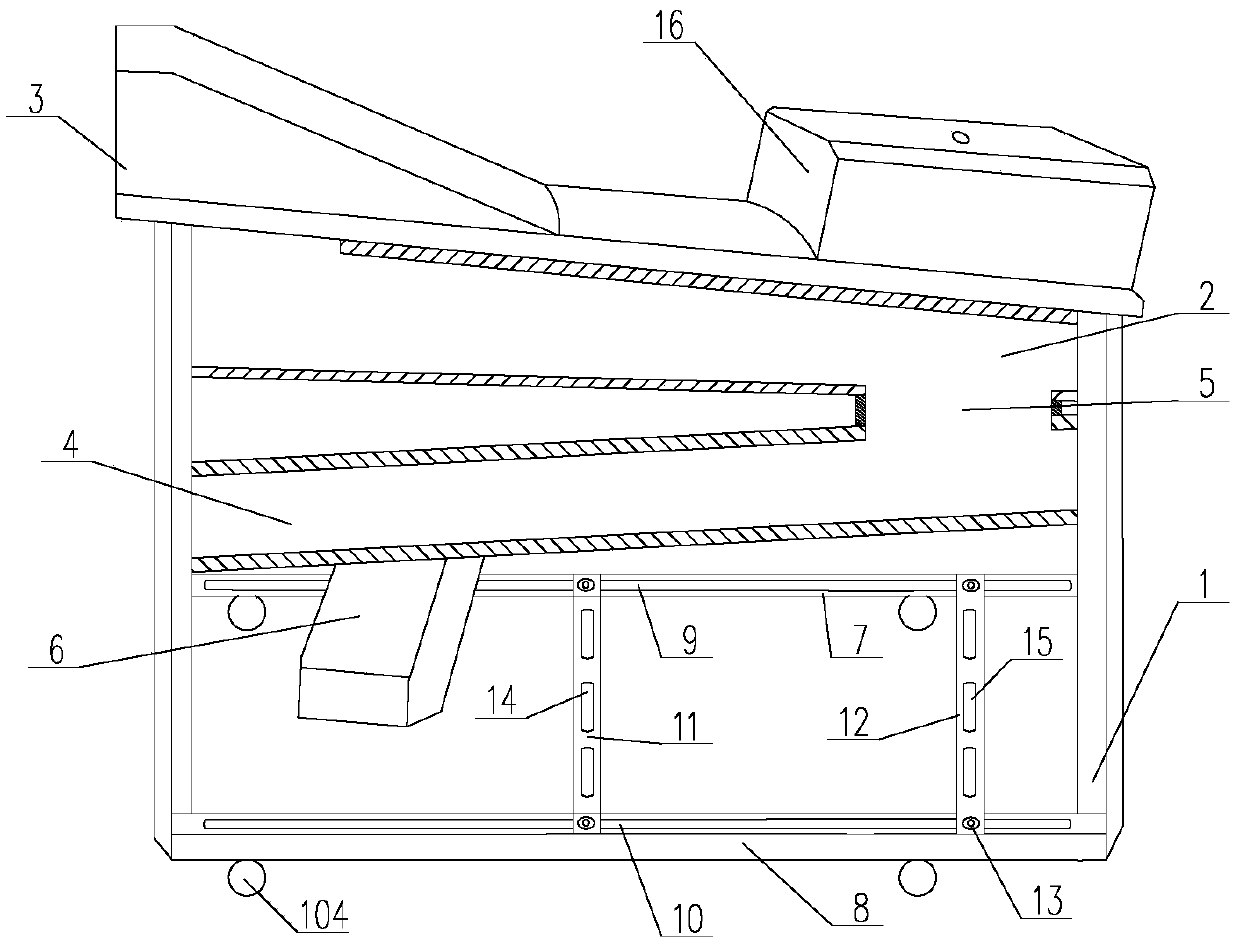

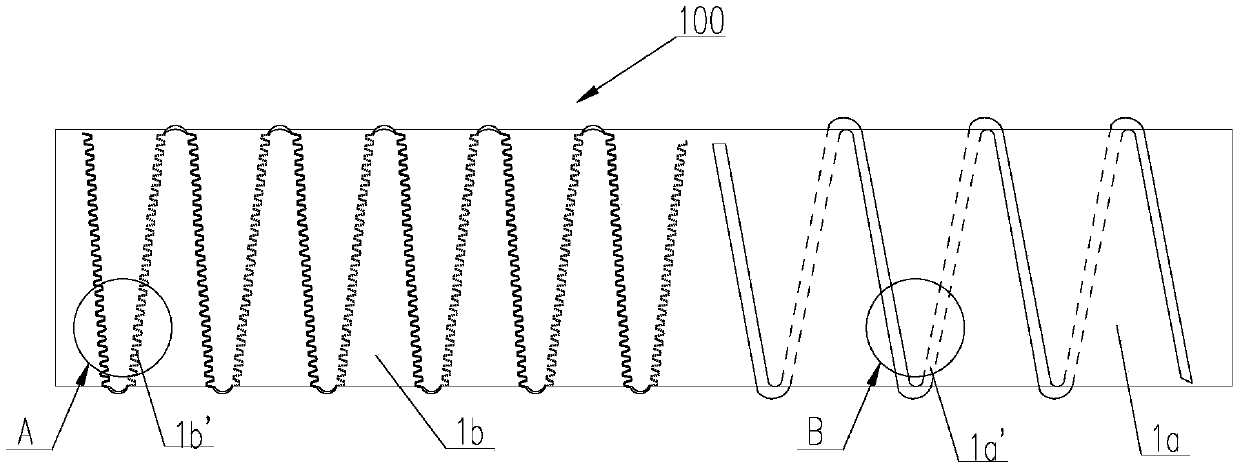

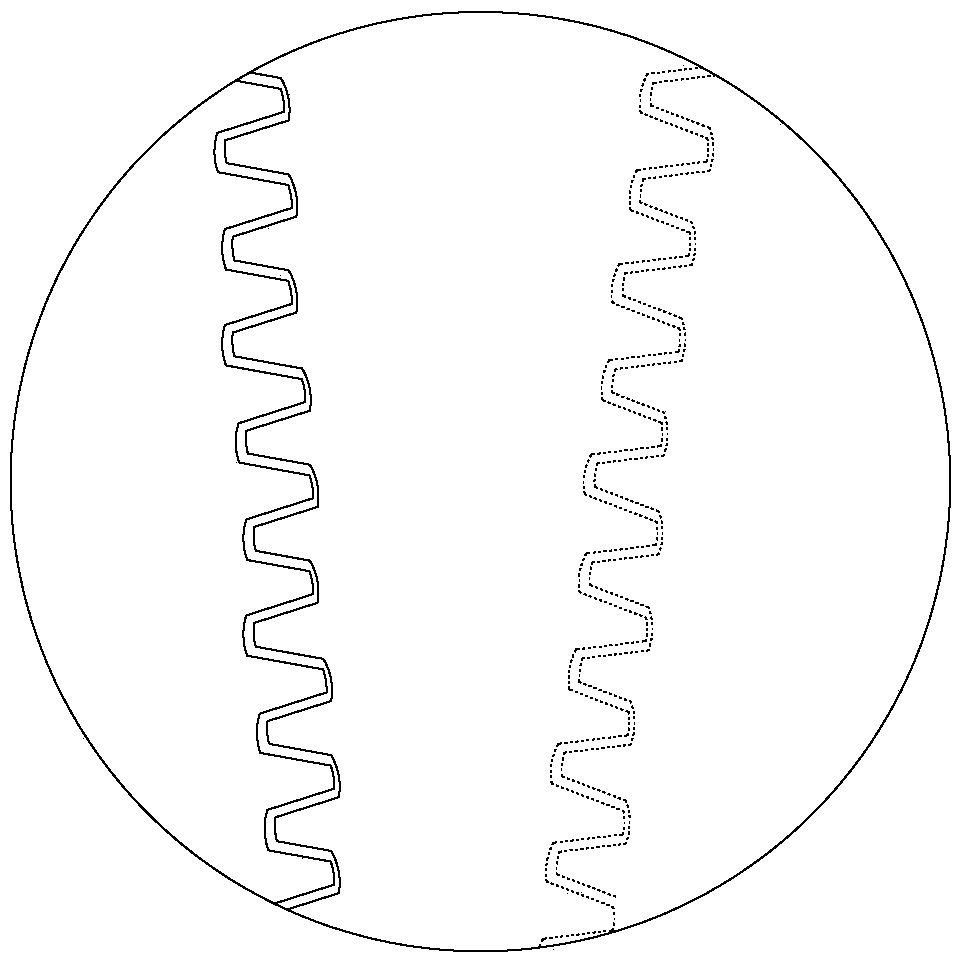

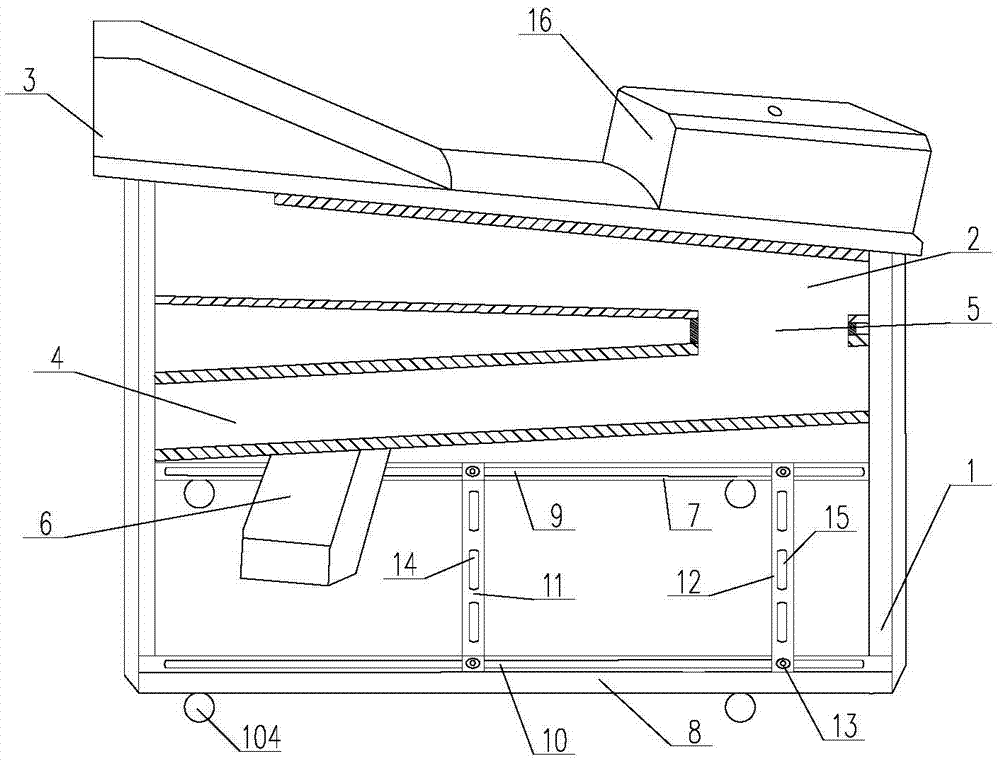

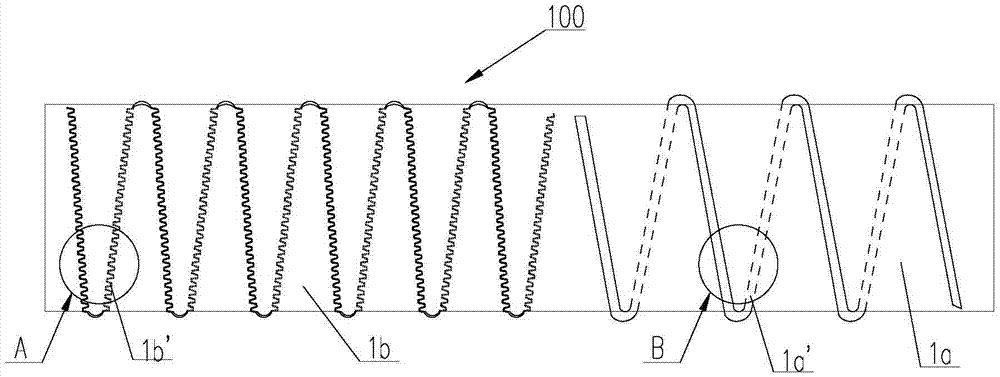

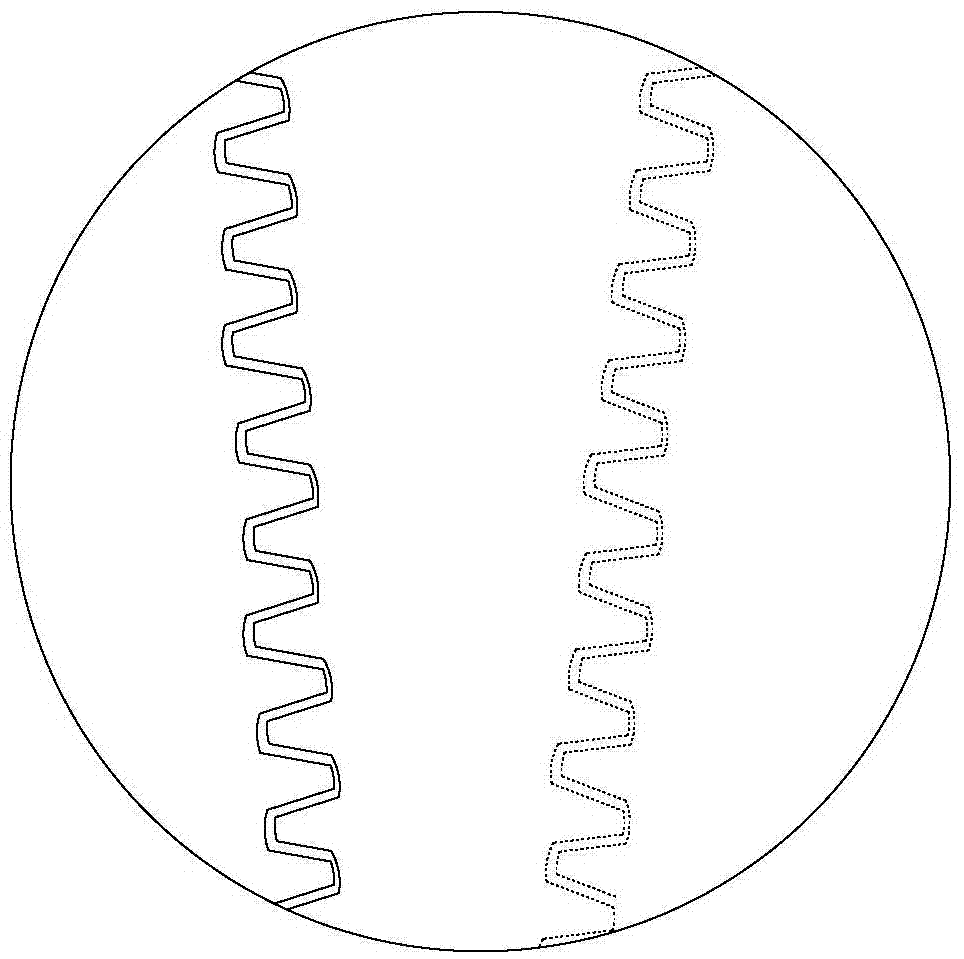

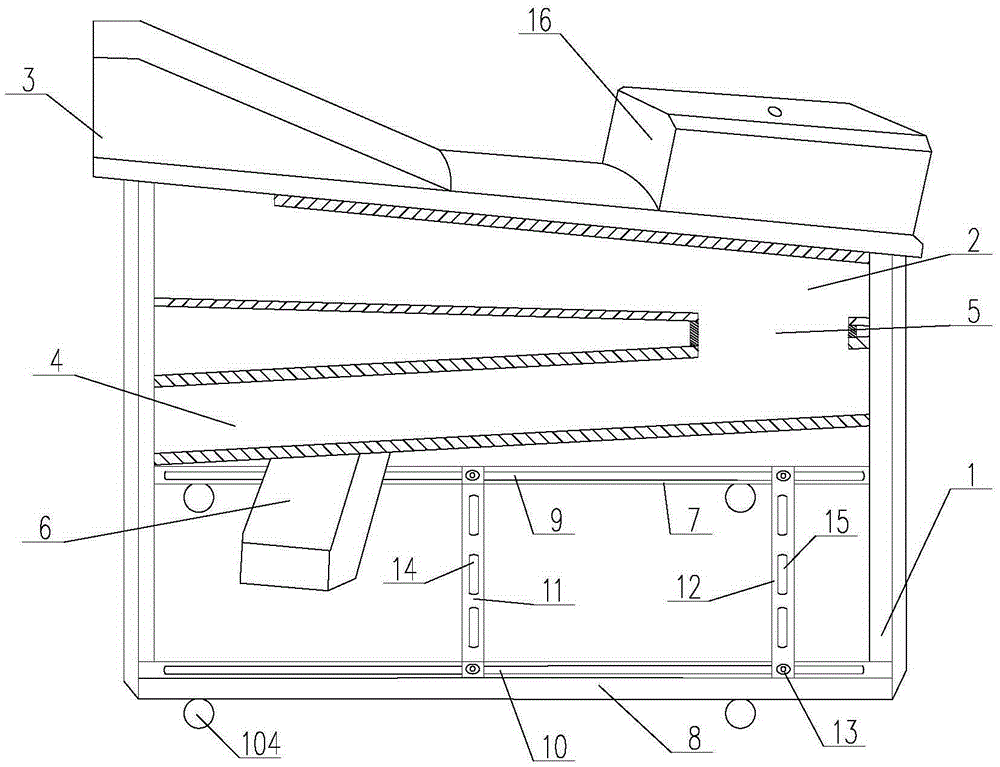

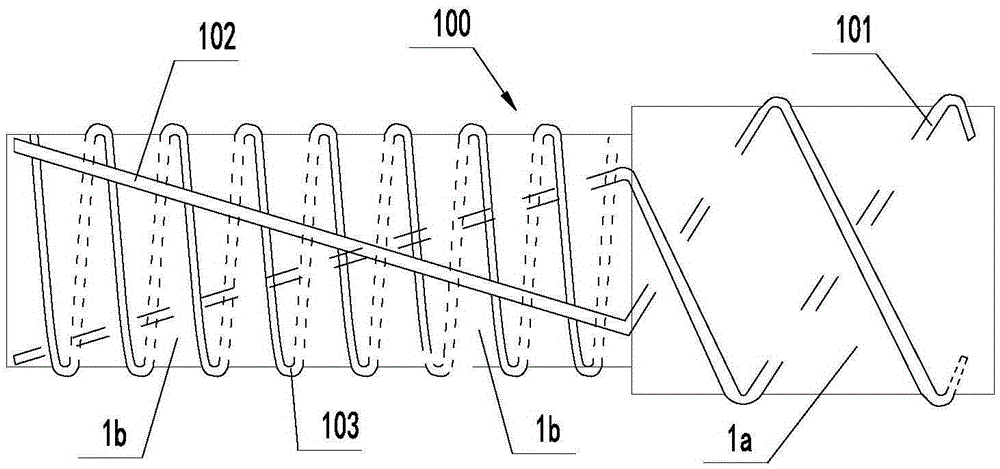

A grain threshing and separating device consists of a feed inlet, an upper cover, a concave grid and a roller; a plurality of arc stock guide plates are arranged on the inner wall of the shell of the feed inlet, each arc stock guide plate is arranged at a deflection angle in relation to the radial direction of the feed inlet; the roller consists of a front section and a rear section, the front section roller takes a conical shape, the rear section roller takes a cylindrical shape, a blade for feeding is welded on the external surface of the front section roller, a plurality of groups of threshing toothholders are welded on the external surface of the rear section roller, each group of the toothholders is arranged along spiral line direction, each toothholder is fixedly connected with a threshing tooth, the toothholder is connected with the threshing tooth in a dismountable way by a bolt fastener; the two ends of the roller are respectively provided with a front spindle nose and a rear spindle nose, and a plurality of arc flow deflectors are obliquely arranged on the top of the inner wall of the upper cover. The grain threshing and separating device has the advantages of fast feeding, thorough threshing, low entrapment loss, is not likely to be blocked by twisting grass, and can thresh a plurality of grains and harvest various grains in fields.

Owner:黄宝玉

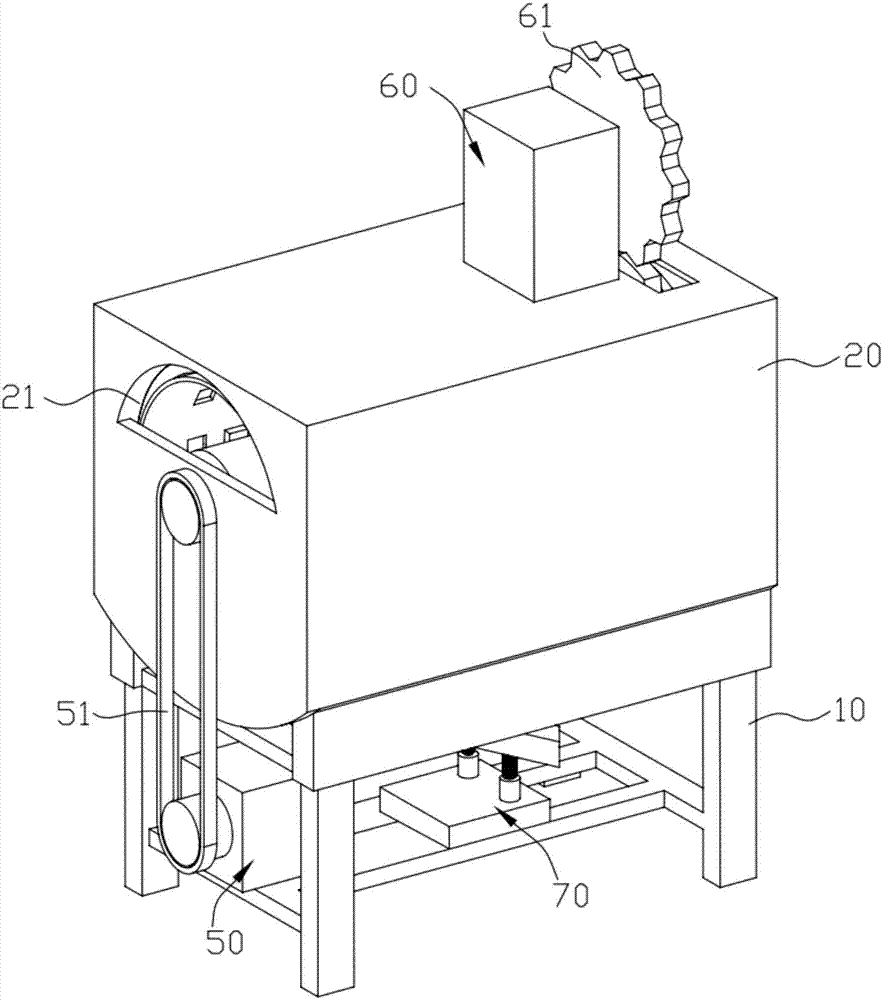

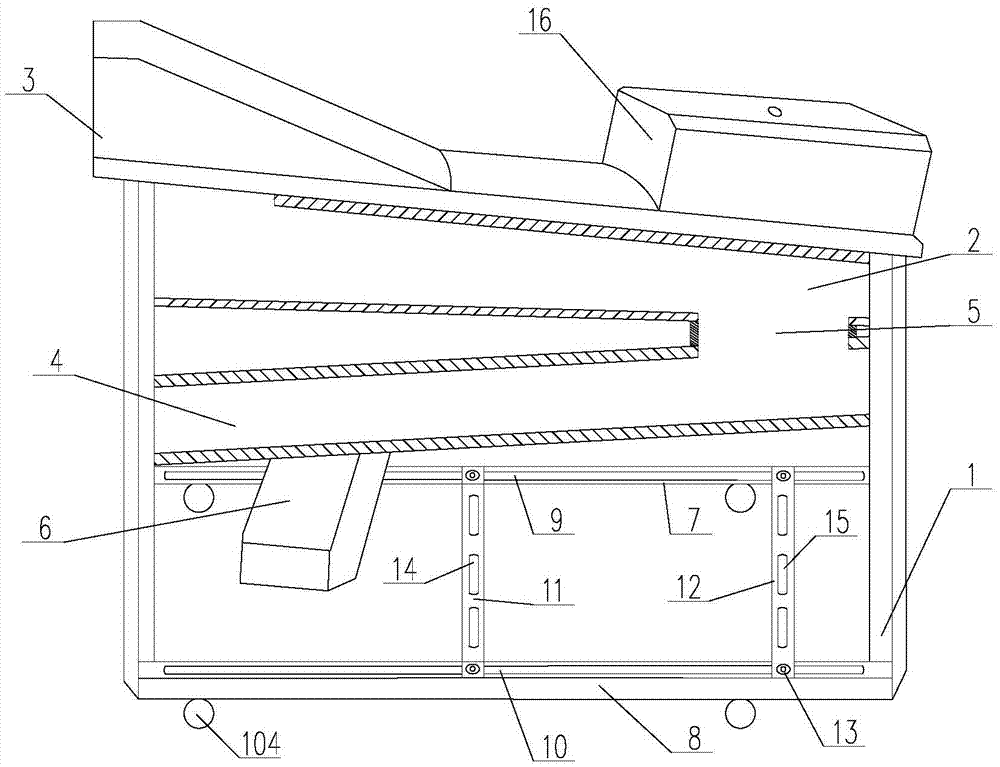

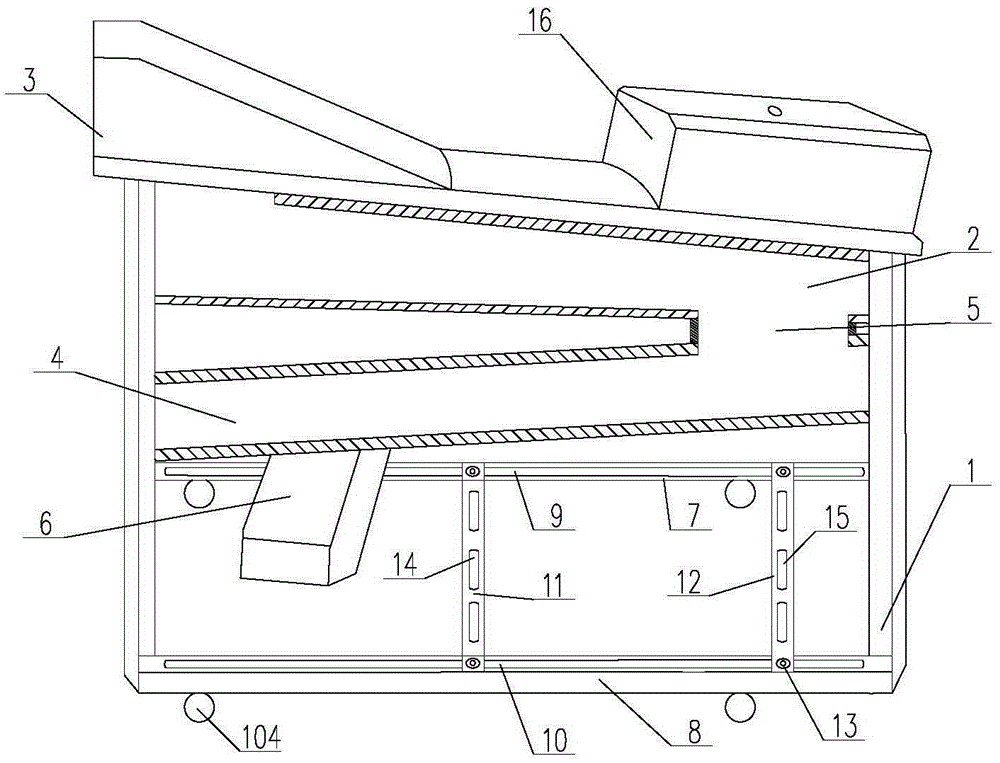

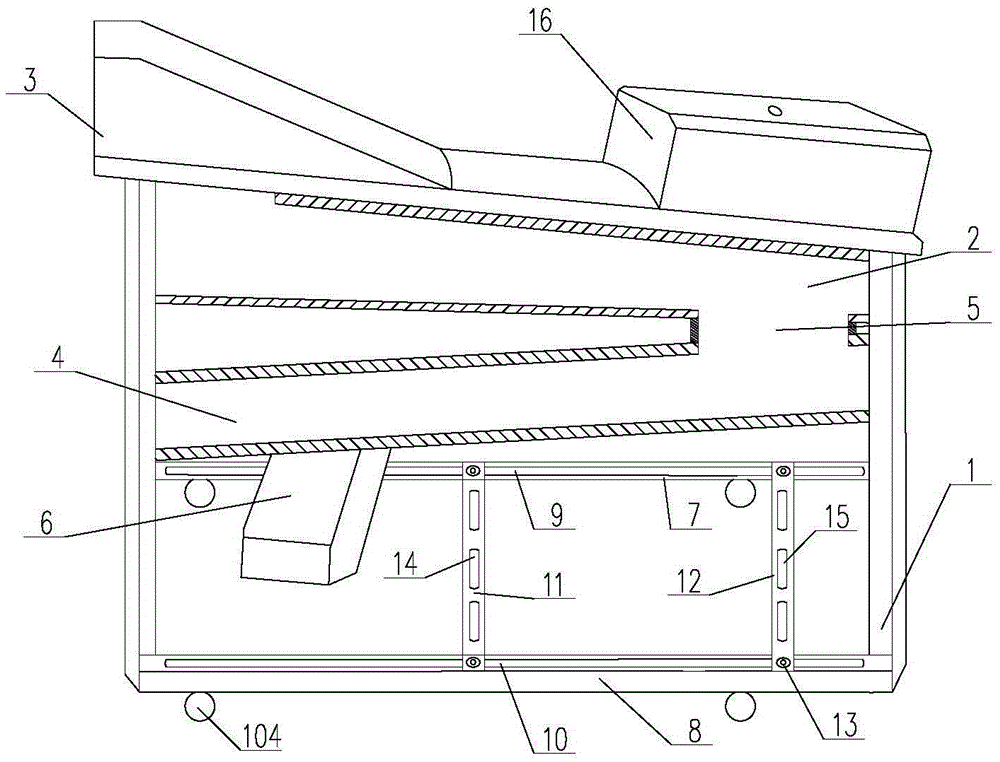

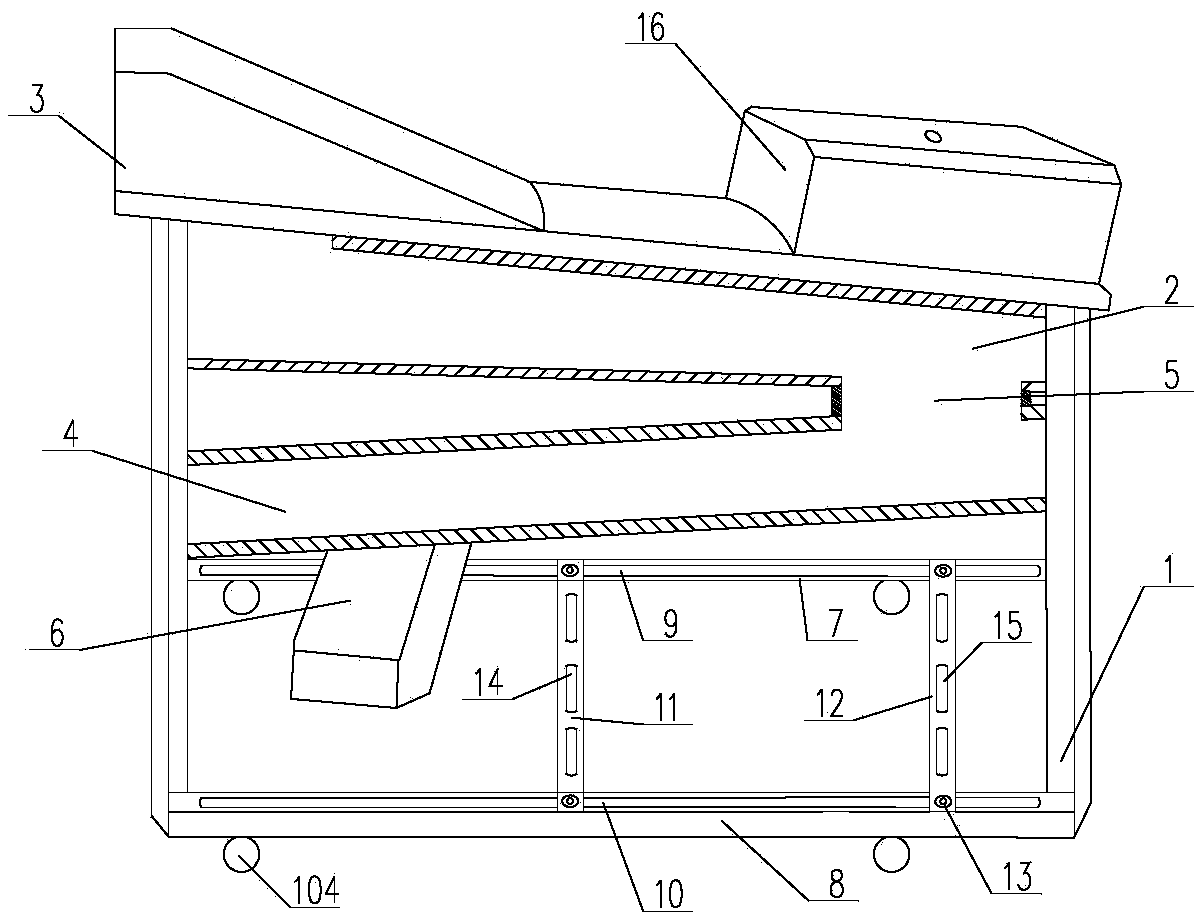

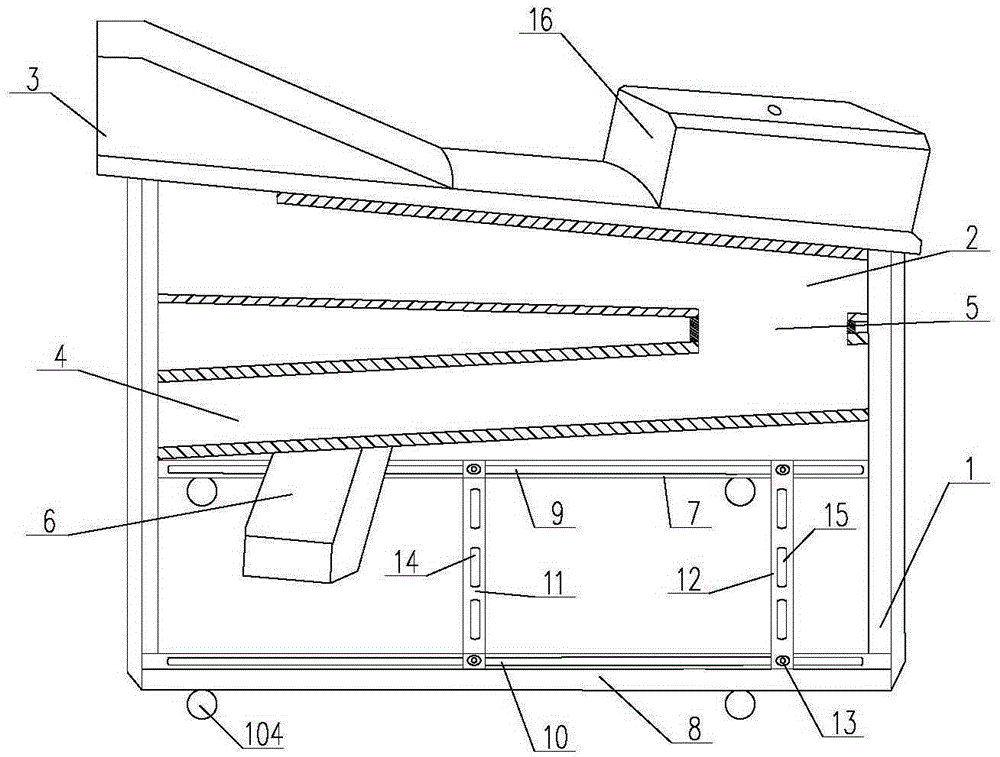

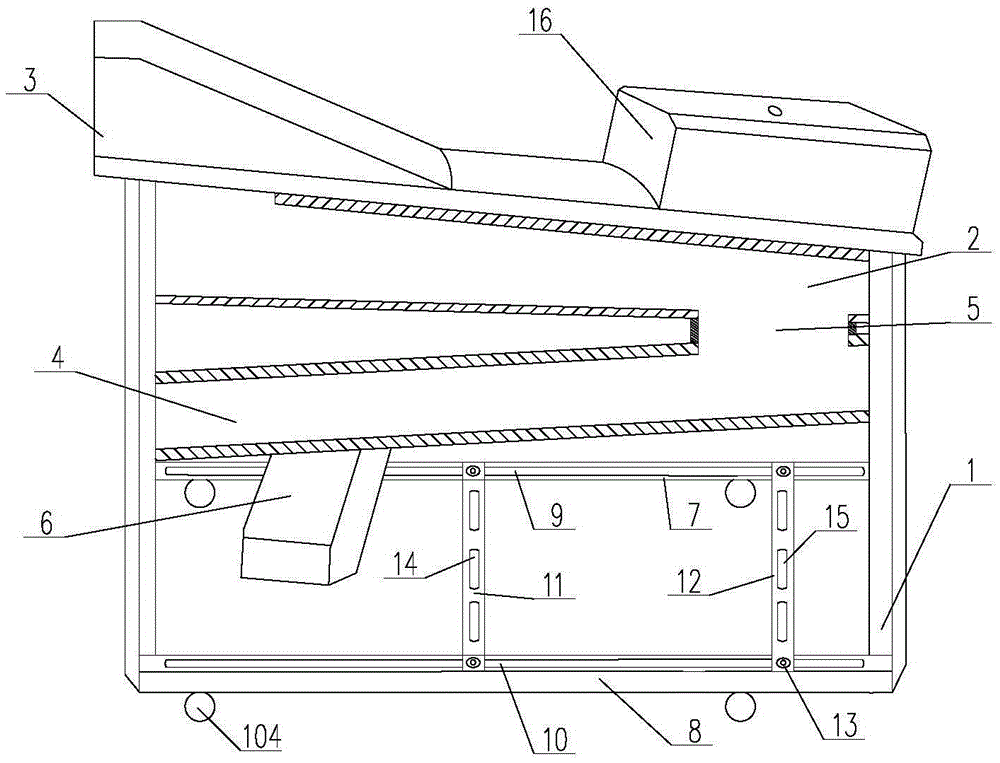

Corn kernel stripper for corn threshing

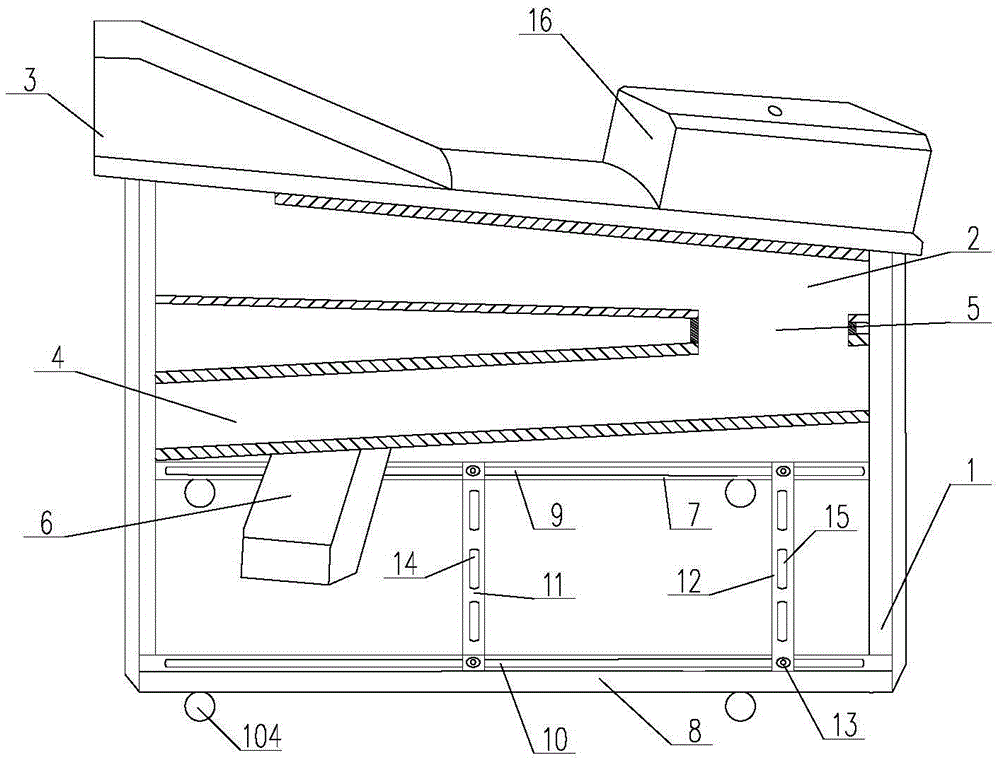

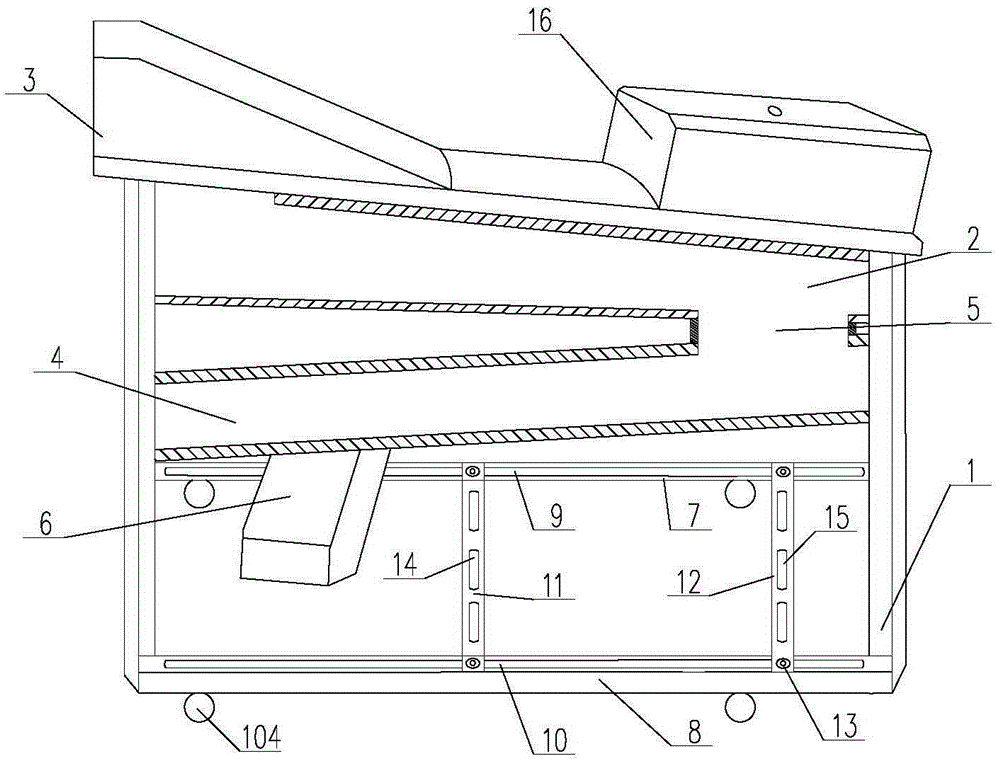

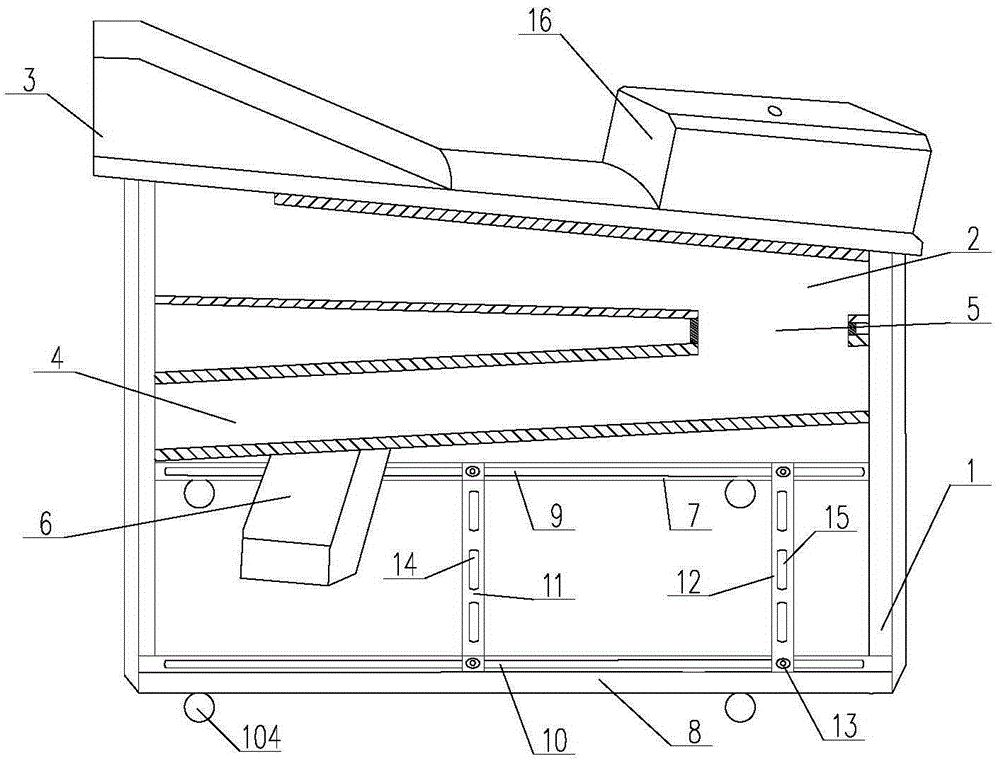

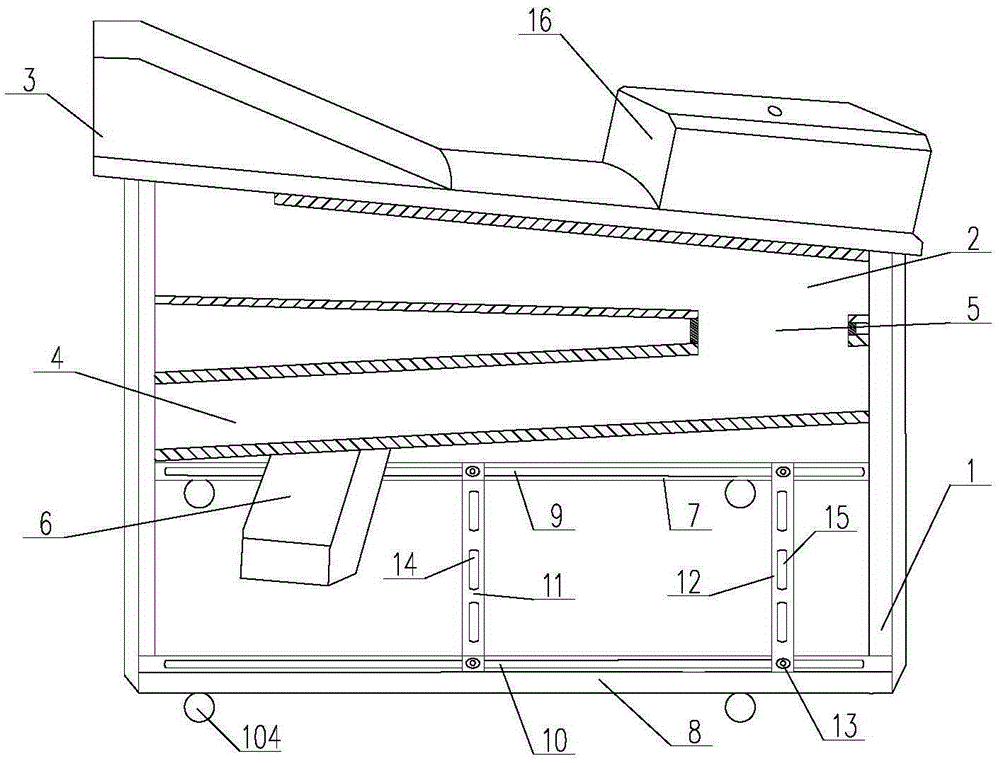

The invention discloses a corn kernel stripper for corn threshing. The corn kernel stripper comprises a cabinet, a first threshing roll, a second threshing roll, a first driving motor and a second driving motor. The cabinet is arranged above a support frame. The first threshing roll and the second threshing roll are arranged in a cavity of the cabinet. The first driving motor is mounted on the support frame. The second driving motor is mounted at the top of the cabinet. The cabinet comprises a feed inlet, a corncob outlet and a corn kernel outlet. The corn kernel outlet is formed in the bottomend face of the cabinet. The second threshing roll is coaxial with the first threshing roll. The diameter value of the inner circumference of the second threshing roll is larger than that of the first threshing roll. A spiral conveying sheet and a plurality of spike teeth are formed on the circumference of the first threshing roll. A plurality of screen holes and auxiliary threshing blocks are formed on the second threshing roll. The corn kernel stripper has the advantages of capability of increasing corn threshing speed, high working efficiency and good threshing effect.

Owner:ANHUI SCI & TECH UNIV

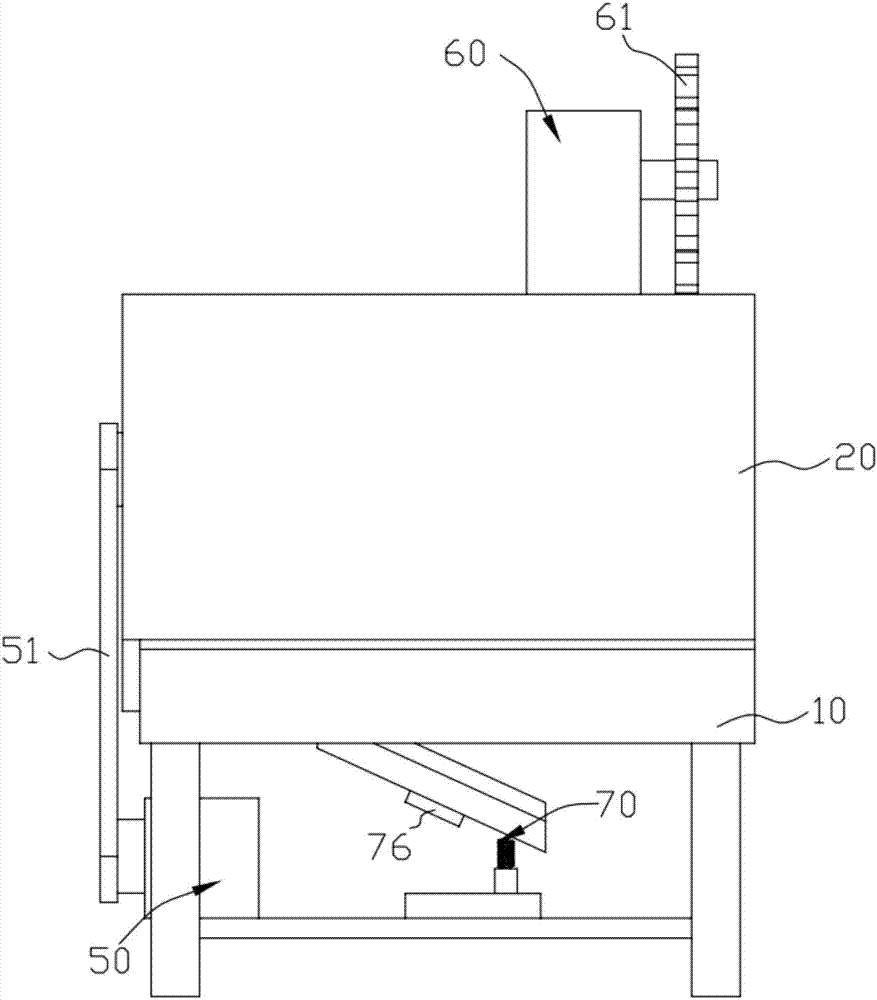

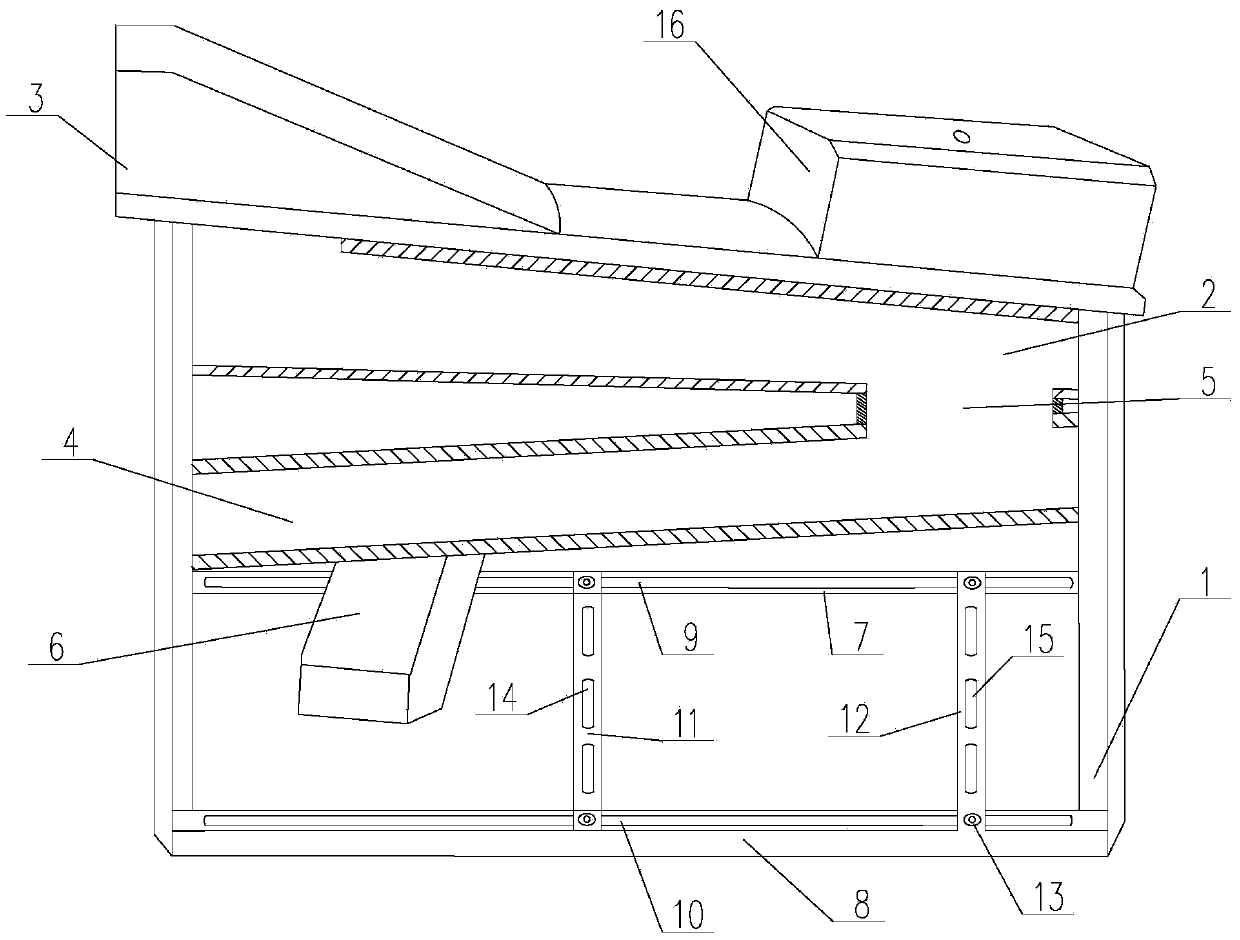

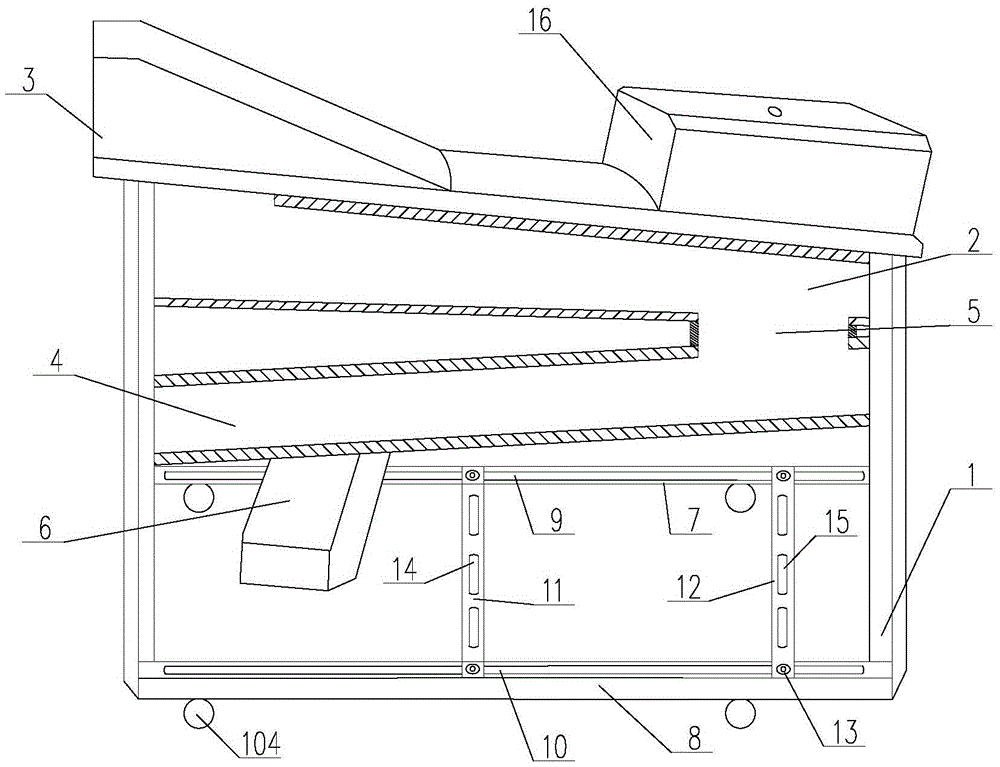

Threshing machine for accelerating threshing

The invention discloses a threshing machine for accelerating threshing. The threshing machine comprises a rack and a first threshing cabin, and the first threshing cabin is arranged on the rack with the front portion higher than the rear portion; the bottom of the rack is provided with a braking wheel and an engine adjusting device; the engine adjusting device comprises a first transverse rod and a second transverse rod, the first transverse rod is parallel to the second transverse rod, and a first transverse rod adjusting hole and a second transverse rod adjusting hole are formed in the length direction of the first transverse rod and the second transverse rod respectively. The threshing machine for accelerating threshing has the advantages that the corn threshing rate is raised; corn kernels are prevented from being damaged in the threshing process; safety performance is improved while the service life of a transmission belt is prolonged; the transformation cost is low, and the threshing speed is raised.

Owner:重庆市靳彬农业科技有限公司

Thresher for corn cobs

The invention discloses a thresher for corn cobs. The thresher comprises a rack and a first threshing bin which is arranged on the rack in a mode of being high in front and low in back. Brake wheels are arranged at the bottom of the rack, a first feeding port is formed in the upper portion of the front end of the first threshing bin, and a first discharging port is formed in the rear end of the first threshing bin. A second threshing bin is arranged on the rack and disposed below the first threshing bin, and the second threshing bin is arranged on the rack in a mode of being high in front and low in back. A second feeding port is formed in the high end of the second threshing bin and connected with the first discharging port through a corn threshing connecting bin, a second discharging port is formed in the low end of the second threshing bin, and a splash-proof device is arranged at the second discharging port. The thresher has the advantages that the threshing rate of corn is increased, corn kernels are prevented from being damaged in the threshing process, safety is improved, the service life of a transmission belt is prolonged, the transformation cost is low, and the threshing speed is increased.

Owner:CHONGQING JINGMING AGRI TECH CO LTD

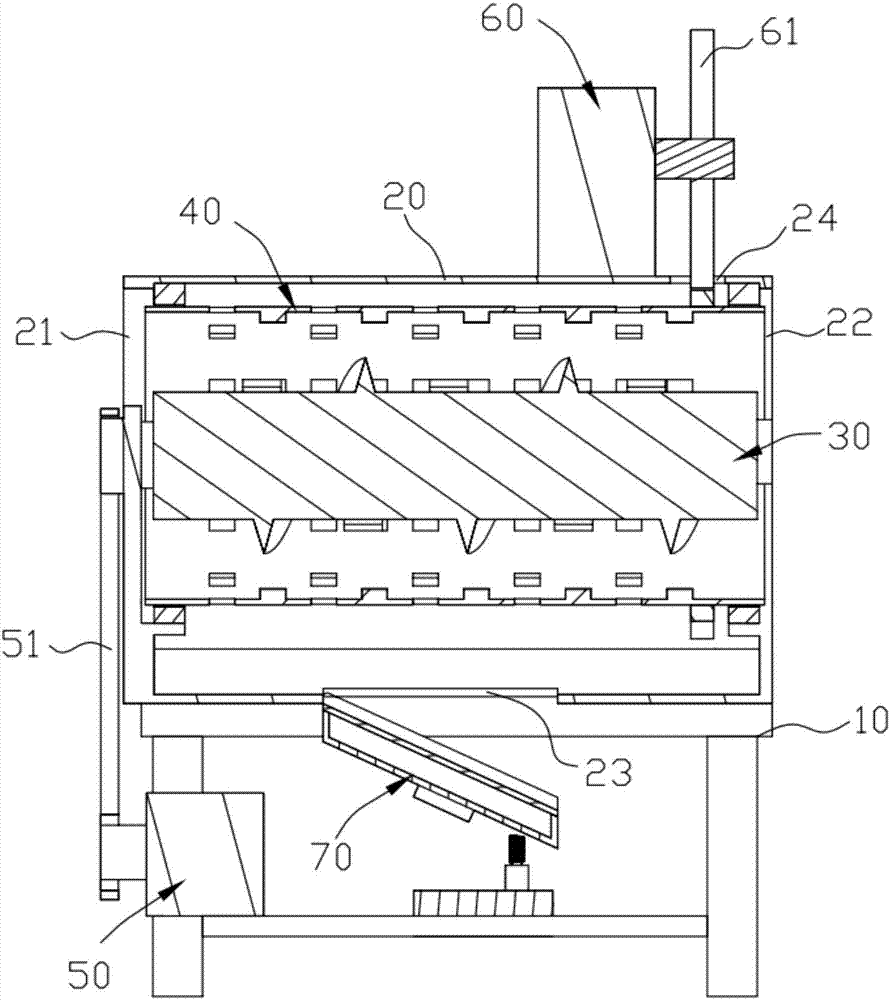

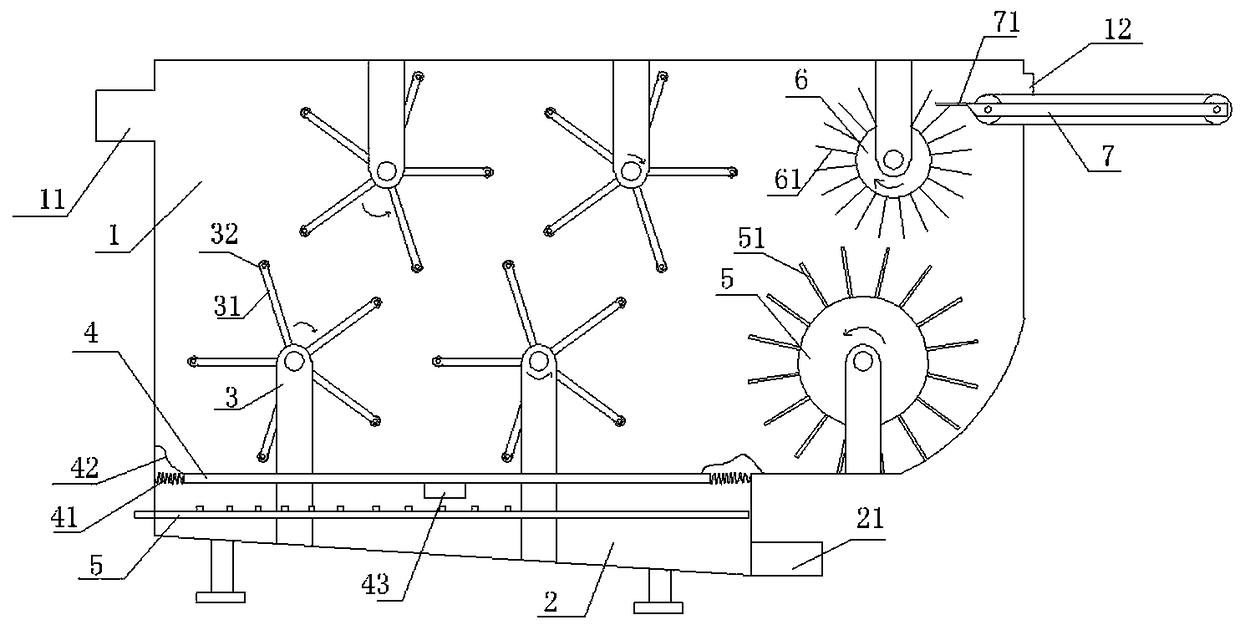

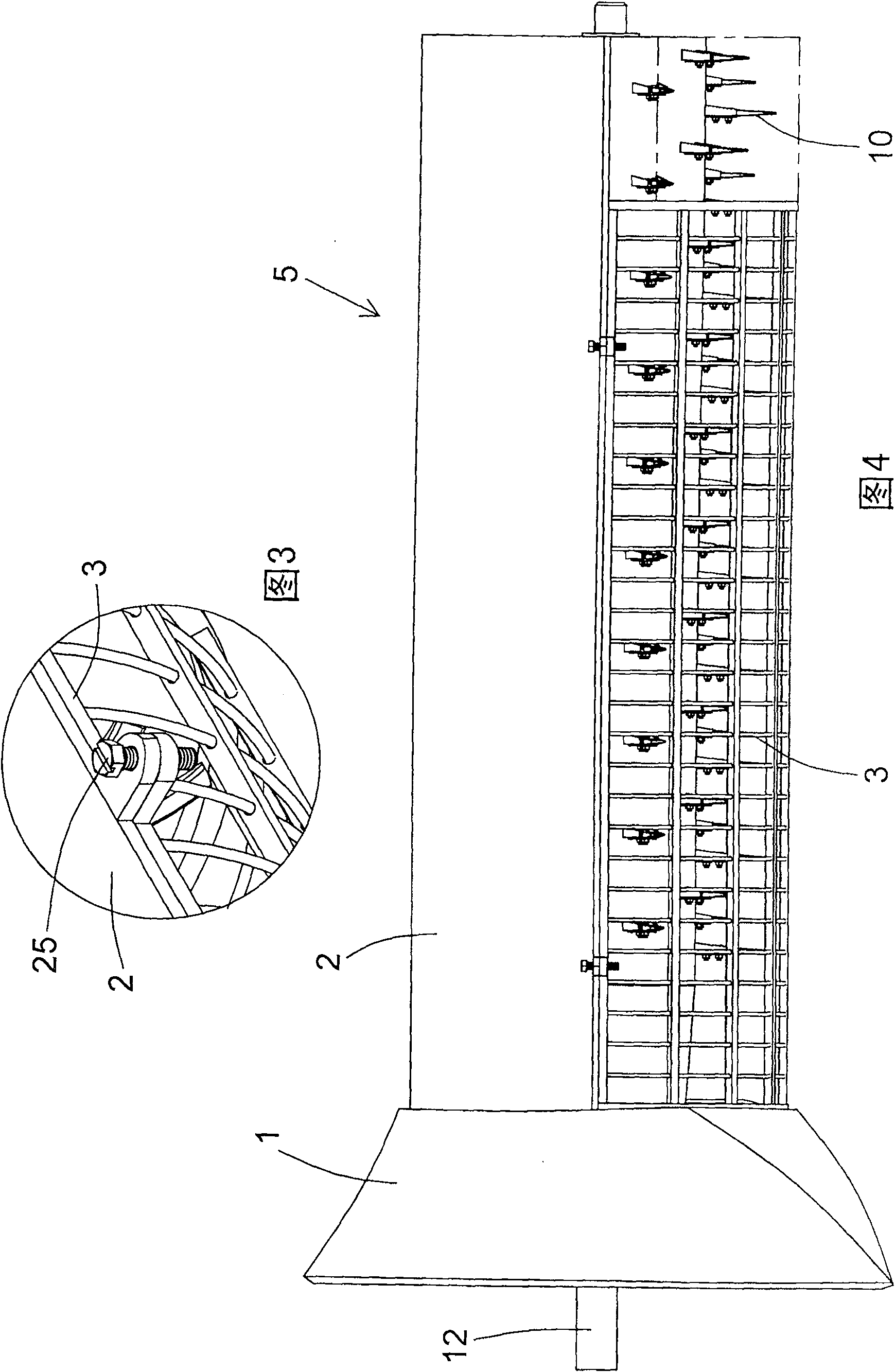

Agricultural threshing machine

InactiveCN108271537AHigh threshing rateImprove threshing speedThreshersAgricultural engineeringThreshing machine

The invention relates to an agricultural threshing machine which comprises a chamber. The chamber is internally partitioned into an upper threshing chamber and a lower discharging chamber by a vibrating screen in horizontal arrangement. The left top and the right top of the threshing chamber are provided with a feeding port and a waste outlet respectively. The bottom wall of the discharging chamber is inclined, and the bottommost end of the bottom wall of the discharging chamber is provided with a discharging port. A plurality of groups of upper and lower threshers are arranged in the threshing chamber, a frame of each upper thresher is connected with the top wall of the threshing chamber, the bottom of a frame of each lower thresher is connected with the bottom wall of the discharging chamber while the top penetrates a notch reserved in the vibrating screen, each frame is connected with a rotating shaft driven by a motor, each rotating shaft is radially provided with a plurality of swing arms, and a threshing drum is arranged at the top of each swing arm. A conveying belt is horizontally arranged at the waste outlet and provided with a straw receiving fork horizontally arranged atthe end of a frame in the chamber, a straw raising drum is arranged on the lateral side of the conveying belt and driven by a motor, a body of the straw raising drum is provided with a plurality of fork rods, and the fork rods and the straw receiving fork are staggered. The agricultural threshing machine has advantages of simple structure, great threshing effects and high efficiency.

Owner:登封市绿奥农林科技有限公司

Splash-proof threshing cylinder

The present invention discloses a splash-proof threshing cylinder. The splash-proof threshing cylinder comprises a frame and a first threshing bin which is arranged on the frame from high to low; the bottom of the frame is provided with brake wheels and an engine adjusting device; and the engine adjusting device comprises a first cross bar and a second cross bar which are parallel to each other, and a first cross bar adjusting hole and a second cross bar adjusting hole are respectively provided in length directions of the first cross bar and the second cross bar. The splash-proof threshing cylinder has the beneficial effects that corn threshing performance is improved; corn kernels are prevented from being damaged during a threshing process; service lifetime of a transmission belt is prolonged when safety performance is improved; and reconstruction cost is low, and threshing speed is increased.

Owner:重庆华楷农业科技有限公司

Device capable of prolonging threshing time

The invention discloses a device capable of prolonging threshing time. The device comprises a rack and a first threshing bin. The first threshing bin is arranged on the rack in a front-high rear-low manner. The bottom of the rack is provided with a brake wheel. A first feed port is arranged on the upper part of the front end of the first threshing bin. The rear end of the first threshing bin is provided with a first discharge port. The rack is provided with a second threshing bin. The second threshing bin is right below the first threshing bin. The second threshing bin is arranged on the rack in a front-low rear-high manner. The high end of the second threshing bin is a second feed port. The second feed port is connected with the first discharge port through a corn threshing connecting bin. The low end of the second threshing bin is provided with a second discharge port. The second discharge port is provided with a splash-proof device. The device improves threshing performance of corns, prevents corn kernels from being damaged in a threshing process, improves safety performance and prolongs service life of a transmission belt. The device has beneficial effects of low transformation cost and improved threshing speed.

Owner:重庆森鑫炬科技有限公司

Roller threshing machine

InactiveCN105453830ATransformation of Chen BenlowImprove threshing speedThreshersThreshing machineTransmission belt

The invention discloses a roller threshing machine comprising a frame and a first threshing bin, and the first threshing bin is arranged on the frame in a way that the front part is higher than the rear part; the bottom of the frame is provided with brake wheels and an engine adjusting device; the engine adjusting device comprises a first cross bar and a second cross bar, the first cross bar is parallel to the second cross bar, and the first cross bar is provided with a first cross bar regulation hole in the length direction, and the second cross bar is provided with a second cross bar regulation hole in the length direction. The roller threshing machine is advantaged in that the corn threshing rate is increased, corn kernels are prevented from being damaged during the threshing process, safety is improved, the service life of a transmission belt is prolonged, the reconstruction cost is low, and the threshing speed is increased and the like.

Owner:重庆森鑫炬科技有限公司

Threshing device

InactiveCN105493780ATransformation of Chen BenlowImprove threshing speedThreshersEngineeringMechanical engineering

The invention discloses a threshing device comprising a rack and a first threshing bin, wherein the first threshing bin is arranged on the rack in a front-high and back-low manner; a brake wheel and an engine adjusting device are arranged at the bottom of the rack; the engine adjusting device comprises a first cross bar and a second cross bar which are parallel with each other, and a first cross bar adjusting hole and a second cross bar adjusting hole are formed in the length direction of the first cross bar and the second cross bar. The threshing device has the benefits that the corn threshing rate is increased, and corn is prevented from being damaged in the threshing process; the service life of a driving belt is prolonged while the safety performance is improved; the transformation cost is low, the threshing speed is increased and the like.

Owner:重庆渝人码头品牌管理有限公司

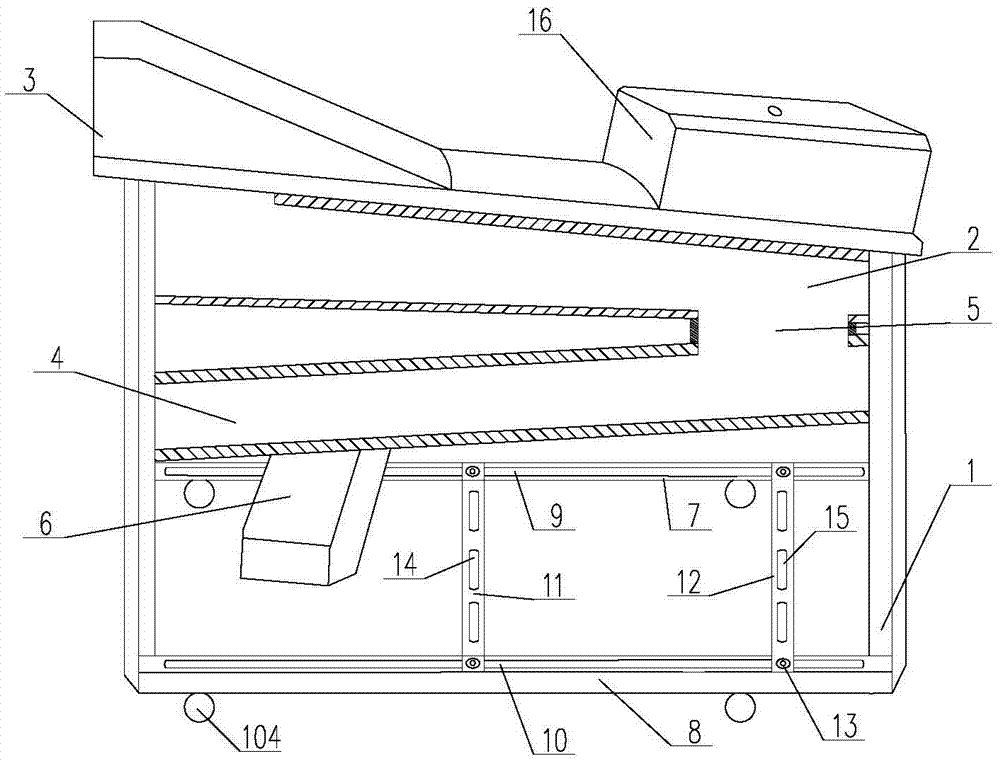

Threshing machine with double threshing cylinders

InactiveCN105340495AImprove cleaning rateImprove threshing speedThreshersThreshing machineComputer engineering

The invention discloses a threshing machine with double threshing cylinders. The threshing machine comprises a rack and a first threshing bin. The first threshing bin is arranged on the rack in a front-high rear-low manner. The first threshing bin is internally provided with a threshing cylinder. The upper part of the front end of the first threshing bin is provided with a first feed port. The rear end of the first threshing bin is provided with a first discharge port. The rack is provided with a second threshing bin. The second threshing bin is right below the first threshing bin. The second threshing bin is arranged on the rack in a front-low rear-high manner. The high end of the second threshing bin is a second feed port. The second feed port is connected with the first discharge port through a corn threshing connecting bin. The low end of the second threshing bin is provided with a second discharge port. The second discharge port is provided with a splash-proof device. The threshing machine can improve threshing performance of corns, and the threshing machine has beneficial effects of low transformation cost, and improving threshing speed.

Owner:CHONGQING CHANGHUI ANIMAL HUSBANDRY CO LTD

Specific corn threshing machine

InactiveCN105359735AImprove cleaning rateImprove threshing speedThreshersEngineeringThreshing machine

The invention discloses a specific corn threshing machine comprising a rack and a first threshing cabin. The first threshing cabin is arranged on the rack with the front part higher than the back part; a threshing rolling cylinder is disposed in the first threshing cabin; a first inlet port is arranged over the front end of the first threshing cabin; a first outlet port is formed in the back end of the first threshing cabin; the rack is provided with a second threshing cabin; the second threshing cabin is arranged right under the first threshing cabin; the second threshing cabin is arranged on the rack with the front part lower than the back part; a high end of the second threshing cabin is provided with a second inlet port; the second inlet port is connected with the first outlet port via a corn threshing connection cabin; a low end of the second threshing cabin is provided with a second outlet port; and the second outlet port part is provided with an anti-splashing device. By the use of the specific corn threshing machine, corn threshing performance can be improved; and the specific corn threshing machine has beneficial effects of low transformation cost and high threshing speed.

Owner:CHONGQING YINGENG ECOLOGICAL AGRI DEV CO LTD

Threshing device with regulation function

The present invention discloses a threshing device with a regulation function. The threshing device comprises a rack and a first threshing chamber, wherein the first threshing chamber which is inclined forward upward is arranged on the rack; a first feed port is formed above the front end of the first threshing chamber, and a first discharge port is formed in the rear end of the first threshing chamber; the rack is provided with a second threshing chamber, the second threshing chamber is positioned under the first threshing chamber, the second threshing chamber which is inclined forward downward is arranged on the rack, the high end of the second threshing chamber is a second feed port, and the second feed port is connected to the first feed port via the corn threshing chamber; and a second discharge port is formed in the lower end of the second threshing chamber, wherein a splash-proof device is arranged at the second discharge port. The threshing device disclosed by the present invention has the advantages that the corn removal rate is improved; the corn kernels are prevented from being destroyed in the threshing process; and the service life of the drive belt is prolonged while the safety performance is improved. The threshing device has the beneficial effects of low modification cost, high threshing velocity and the like.

Owner:重庆渝人码头品牌管理有限公司

Anti-jamming apparatus

The invention discloses an anti-jamming apparatus comprising a rack and a first threshing cabin. The first threshing cabin is mounted on the rack with the front part higher than the back part; the bottom of the rack is provided with a brake wheel and an engine adjusting device; the engine adjusting device is formed by a first transverse rod and a second transverse rod; the first and second transverse rods are parallel to each other; and a first transverse rod adjusting hole and a second transverse rod adjusting hole are formed along the length directions of the first and second transverse rods. The anti-jamming apparatus can improve corn threshing rate and prevent niblets from being damaged during the threshing; safety performance can be improved and service life of a transmission belt can be prolonged; and the anti-jamming apparatus possesses beneficial effects of low improving cost and quick threshing speed.

Owner:重庆市靳彬农业科技有限公司

Novel threshing device

The invention discloses a novel threshing device which comprises a rack and a first threshing bin. The first threshing bin is arranged on the rack in a mode of being high in front and low in back; a brake wheel and an engine adjusting device are arranged at the bottom of the rack; the engine adjusting device comprises a first cross rod and a second cross rod which are parallel with each other, and a first cross rod adjusting hole and a second cross rod adjusting hole are formed in the length directions of the first cross rod and the second cross rod respectively. The novel threshing device has the advantages that the threshing rate of corn is increased; corn kernels are prevented from being damaged in the threshing process; the safety performance is improved, and meanwhile the service life of a transmission belt is prolonged; the transformation cost is low, and the threshing speed is increased.

Owner:重庆仙尼乐贸易有限公司

Adjustable threshing machine

InactiveCN105359747AImprove cleaning rateImprove threshing speedThreshersThreshing machineElectrical and Electronics engineering

The invention discloses an adjustable threshing machine comprising a rack and a first threshing cabin. The first threshing cabin is arranged on the rack with the front part higher than the lower part; a threshing cylinder is disposed in the first threshing cabin; a first charging port is formed over the front end of the first threshing cabin; a first discharging port is formed in the back end of the first threshing cabin; the rack is provided with a second cabin and the second cabin is arranged right under the first threshing cabin; the second threshing cabin is mounted on the rack with the front part lower than the back part; the higher end of the second threshing cabin is provided with a second charging port; the second charging port is connected with the first discharging port via a corn threshing connection cabin; a second discharging port is formed in the lower end of the second threshing cabin; and the second discharging port is provided with an anti-splashing device. Corn threshing rate can be improved by the use of the double-threshing cabin-contained threshing machine; and the double-threshing cabin-contained threshing machine has beneficial effects of low improving cost and high threshing speed.

Owner:CHONGQING CHANGHUI ANIMAL HUSBANDRY CO LTD

Anti-jamming threshing cylinder

The invention discloses an anti-jamming threshing cylinder. The anti-jamming threshing cylinder comprises a machine frame and a first threshing bin, wherein the first threshing bin is arranged on the machine frame with the front portion higher than the rear portion, a brake wheel and an engine adjusting device are arranged on the bottom of the machine frame, the engine adjusting device comprises a first cross bar and a second cross bar, the first cross bar is parallel to the second cross bar, and a first cross bar adjusting hole and a second cross bar adjusting hole are formed in the length direction of the first cross bar and the length direction of the second cross bar respectively. By the adoption of the anti-jamming threshing cylinder, the corn threshing rate is increased, corn kernels are prevented from being damaged during threshing, safety performance is improved, the service life of a transmission belt is prolonged, transformation cost is low, and the threshing speed is increased.

Owner:CHONGQING JINGMING AGRI TECH CO LTD

Threshing rib capable of quickly threshing

The invention discloses a threshing rib capable of quickly threshing. The threshing rib comprises a rack and a first threshing cabin, wherein the first threshing cabin is mounted on the rack with the front part higher than the back part; the bottom of the rack is provided with brake wheels and an engine adjusting device; the engine adjusting device is formed by a first cross rod and a second cross rod; the first and second cross rods are parallel to each other; and a first cross rod adjusting hole and a second cross rod adjusting hole are respectively formed in the first and second cross rods along the length directions of the same. Corn threshing rate can be improved; damage to niblets during the threshing can be prevented; safety performance can be improved and service life of the transmission belt can be prolonged; and the threshing rib has benefits of low improvement cost and increased threshing speed.

Owner:重庆仙尼乐贸易有限公司

Anti-jamming dual-roller threshing device

InactiveCN105453833ATransformation of Chen BenlowImprove threshing speedThreshersAnti jammingEngineering

The invention discloses an anti-jamming dual-roller threshing device. The anti-jamming dual-roller threshing device comprises a frame and a first threshing bin, and the first threshing bin is arranged on the frame in a way that the front part is higher than the rear part; the bottom of the frame is provided with brake wheels and an engine adjusting device; the engine adjusting device comprises a first cross bar and a second cross bar, the first cross bar is parallel to the second cross bar, and the first cross bar is provided with a first cross bar regulation hole in the length direction, and the second cross bar is provided with a second cross bar regulation hole in the length direction. The anti-jamming dual-roller threshing device is advantaged in that the corn threshing rate is increased, corn kernels are prevented from being damaged during the threshing process, safety is improved, the service life of a transmission belt is prolonged, the reconstruction cost is low, and the threshing speed is increased and the like.

Owner:CHONGQING HONGWEI MOLD DESIGN CO LTD

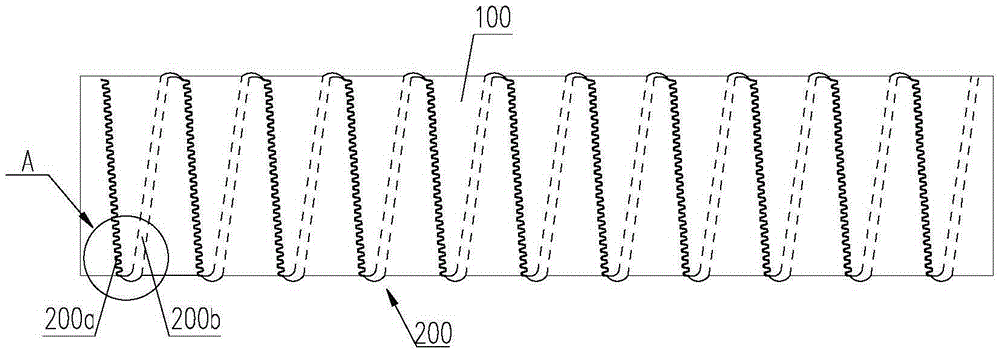

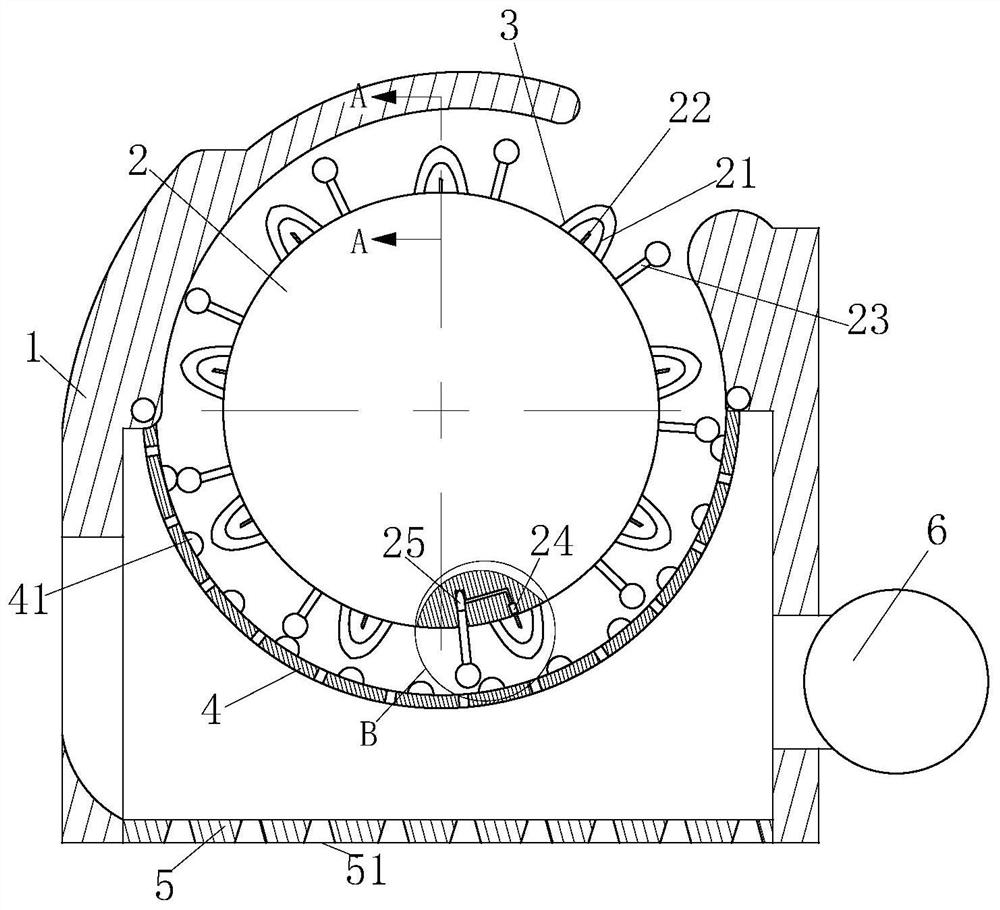

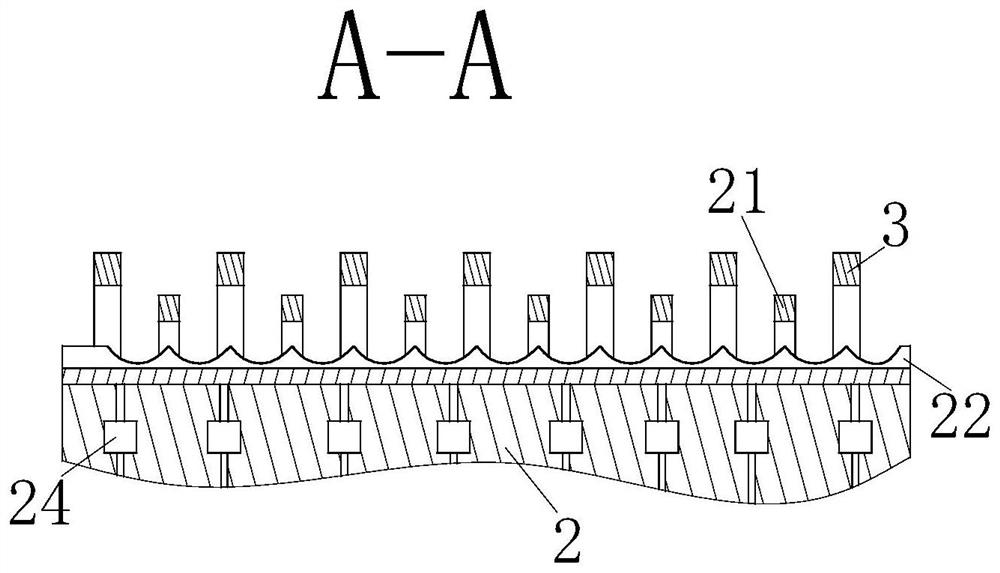

Grain threshing and separating device

A grain threshing and separating device consists of a feed inlet, an upper cover, a concave grid and a roller; a plurality of arc stock guide plates are arranged on the inner wall of the shell of the feed inlet, each arc stock guide plate is arranged at a deflection angle in relation to the radial direction of the feed inlet; the roller consists of a front section and a rear section, the front section roller takes a conical shape, the rear section roller takes a cylindrical shape, a blade for feeding is welded on the external surface of the front section roller, a plurality of groups of threshing toothholders are welded on the external surface of the rear section roller, each group of the toothholders is arranged along spiral line direction, each toothholder is fixedly connected with a threshing tooth, the toothholder is connected with the threshing tooth in a dismountable way by a bolt fastener; the two ends of the roller are respectively provided with a front spindle nose and a rear spindle nose, and a plurality of arc flow deflectors are obliquely arranged on the top of the inner wall of the upper cover. The grain threshing and separating device has the advantages of fast feeding, thorough threshing, low entrapment loss, is not likely to be blocked by twisting grass, and can thresh a plurality of grains and harvest various grains in fields.

Owner:黄宝玉

Double-threshing cabin-contained threshing machine

InactiveCN105359743AImprove cleaning rateImprove threshing speedThreshersEngineeringThreshing machine

The invention discloses a double-threshing cabin-contained threshing machine comprising a rack and a first threshing cabin. The first threshing cabin is arranged on the rack with the front part higher than the lower part; a threshing cylinder is disposed in the first threshing cabin; a first charging port is formed over the front end of the first threshing cabin; a first discharging port is formed in the back end of the first threshing cabin; the rack is provided with a second cabin and the second cabin is arranged right under the first threshing cabin; the second threshing cabin is mounted on the rack with the front part lower than the back part; the higher end of the second threshing cabin is provided with a second charging port; the second charging port is connected with the first discharging port via a corn threshing connection cabin; a second discharging port is formed in the lower end of the second threshing cabin; and the second discharging port is provided with an anti-splashing device. Corn threshing rate can be improved by the use of the double-threshing cabin-contained threshing machine; and the double-threshing cabin-contained threshing machine has beneficial effects of low improving cost and high threshing speed.

Owner:CHONGQING CHANGHUI ANIMAL HUSBANDRY CO LTD

Corn threshing machine

InactiveCN105393718AImprove cleaning rateImprove threshing speedThreshersAgricultural engineeringThreshing machine

The invention discloses a corn threshing machine comprising a machine frame and a first threshing chamber arranged on the machine frame in a front-high rear-low manner; a threshing cylinder is arranged in the first threshing chamber; a first feeding port is arranged above the front end of the first threshing chamber, and the rear end of the first threshing chamber is provided with a first discharge port; the machine frame is provided with a second threshing chamber arranged right below the first threshing chamber; the second threshing chamber is arranged on the machine frame in a front-low rear-high manner; the high end of the second threshing chamber is the second feeding port; the second feeding port is connected with the first discharge port through a corn threshing connecting chamber; the low end of the second threshing chamber is provided with a second discharge port having an anti-splashing device. The threshing machine can improve corn threshing rate, is low in reconstruction cost, and can improve threshing speed.

Owner:CHONGQING CHANGHUI ANIMAL HUSBANDRY CO LTD

Anti-jamming threshing rib

The invention discloses an anti-jamming threshing rib comprising a rack and a first threshing cabin. The first threshing cabin is mounted on the rack with the front part higher than the back part; the bottom of the rack is provided with a brake wheel and an engine adjusting device; the engine adjusting device is formed by a first transverse rod and a second transverse rod; the first and second transverse rods are parallel to each other; and a first transverse rod adjusting hole and a second transverse rod adjusting hole are formed along the length directions of the first and second transverse rods. The anti-jamming threshing rib can improve corn threshing rate and prevent niblets from being damaged during the threshing; safety performance can be improved and service life of a transmission belt can be prolonged; and the anti-jamming threshing machine possesses beneficial effects of low improving cost and quick threshing speed.

Owner:CHONGQING ATEC TEST EQUIP

Threshing device convenient to move

The invention discloses a threshing device convenient to move. The threshing device comprises a rack and a first threshing bin, and the first threshing bin is arranged on the rack in the mode that the front is higher than the rear. A braking wheel is arranged at the bottom of the rack. A first feed port is formed in the upper portion of the front end of the first threshing bin, and a first discharge port is formed in the rear end of the first threshing bin. A second threshing bin is arranged on the rack in the mode that the front is lower than the rear and located under the first threshing bin. A second feed port is formed in the high end of the second threshing bin and connected with the first discharge port through a corn threshing connecting bin. The lower end of the second threshing bin is provided with a second discharge port which is provided with an anti-splashing device. The threshing device convenient to move has the advantages that the corn threshing rate is increased; corn kernels are prevented from being damaged in the threshing process; the service life of a transmission belt is prolonged while safety performance is improved; transformation cost is low, and threshing speed is increased.

Owner:重庆市荣昌区汇鑫机械制造厂

Adjustable threshing machine

InactiveCN106856877AImprove cleaning rateImprove threshing speedThreshersEngineeringThreshing machine

The invention discloses an adjustable threshing machine, comprising a frame and a first threshing bin, the first threshing bin is arranged on the frame with a front height and a rear low position; a threshing cylinder is arranged in the first threshing bin, There is a first feed inlet above the front end of the first threshing bin, a first outlet is provided at the rear end of the first threshing bin, a second threshing bin is arranged on the frame, the second threshing bin is located directly below the first threshing bin, and the second threshing bin is located directly below the first threshing bin. The second threshing bin is set on the frame with the front low and the rear high. The high end of the second threshing bin is the second feed port, and the second feed port is connected with the first discharge port through the corn threshing connection bin; the second threshing bin There is a second outlet at the lower end, and an anti-splash device is installed at the second outlet; the invention can improve the removal rate of corn, has the beneficial effects of low cost of transformation, and improved threshing speed.

Owner:重庆仙尼乐贸易有限公司

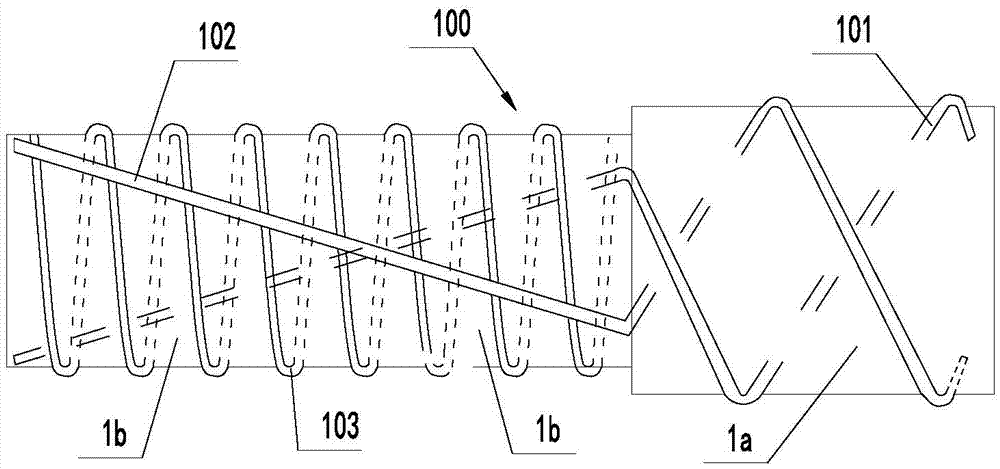

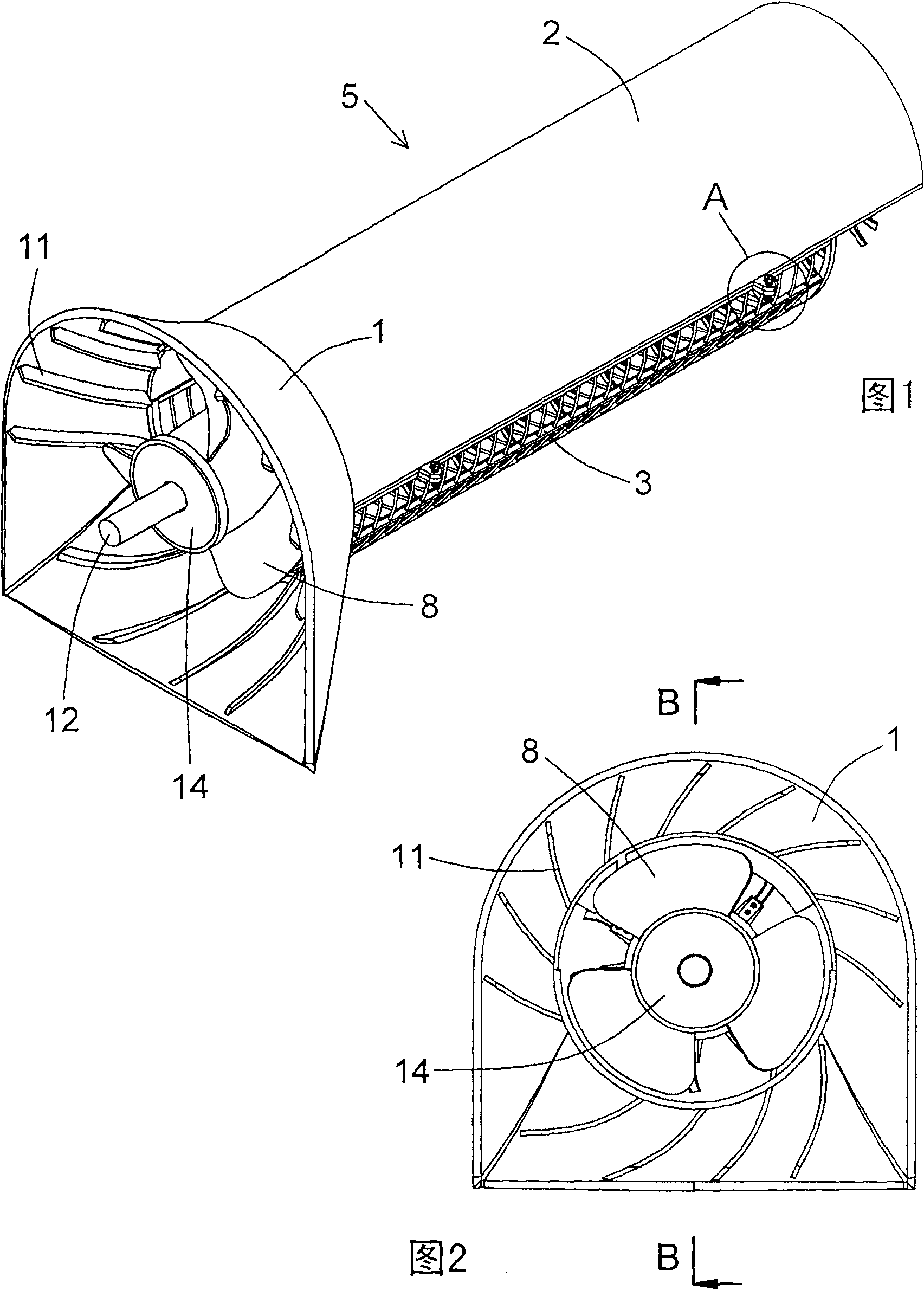

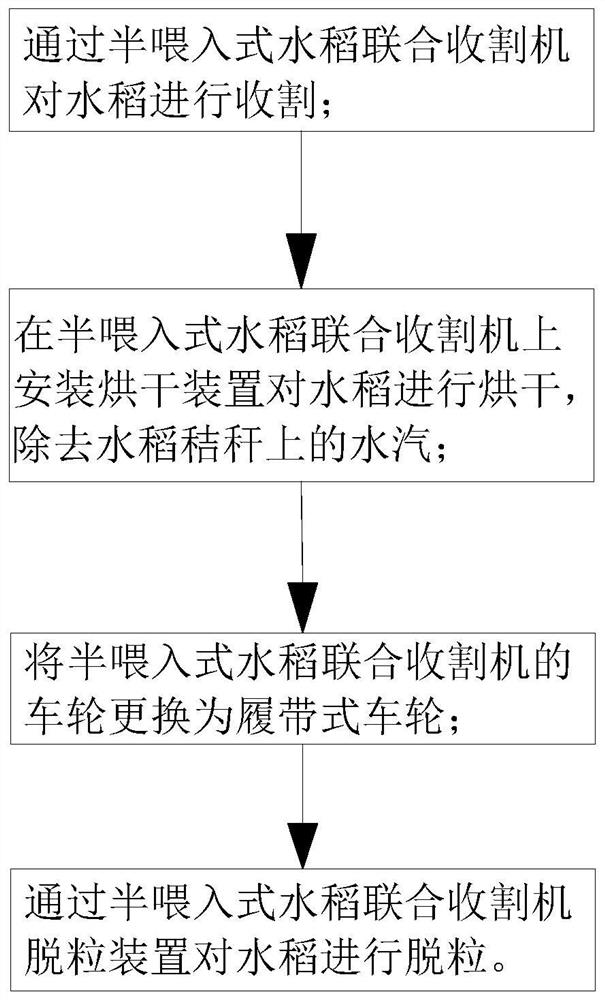

A method of improving rice harvesting efficiency

ActiveCN109121667BImprove harvesting efficiencyImprove threshing efficiencyMowersThreshersThreshingCombine harvester

The invention belongs to the technical field of rice harvesting, and specifically relates to a method for improving rice harvesting efficiency. The method comprises the following steps: harvesting rice by a half-feeding rice combine harvester; Install a drying device to dry the rice and remove the water vapor on the rice straw; replace the wheels of the semi-feeding rice combine harvester with crawler wheels; use the threshing device of the semi-feeding rice combine harvester to thresh the rice; The invention can significantly improve the rice harvesting efficiency, and the invention is suitable for harvesting rice in a large area.

Owner:许可

Threshing rib

The invention discloses a threshing rib comprising a frame and a first threshing chamber; the first threshing rib is arranged on the frame in a high-front low-rear manner; the bottom of the frame is provided with a brake wheel and an engine adjusting device; the engine adjusting device comprises a first transverse rod and a second transverse rod arranged in parallel; a first transverse rod adjusting hole and a second transverse rod adjusting hole are respectively arranged on the first and second transverse rods in the length direction. The threshing rib can improve corn threshing rate, can prevent corns from being damaged in a threshing process, thus improving safety performance, and prolonging driving belt service life; the threshing rib is low in reconstruction cost, and can improve threshing speed.

Owner:重庆市荣昌区汇鑫机械制造厂

Threshing rib capable of improving threshing efficiency

The invention discloses a threshing rib capable of improving threshing efficiency. The threshing rib comprises a rack and a first threshing bin, and the first threshing bin is arranged on the rack with the front high and the back low; braking wheels and an engine adjusting device are arranged at the bottom of the rack; the engine adjusting device comprises a first cross rod and a second cross rod, the first cross rod and the second cross rod are parallel to each other, and a first cross rod adjusting hole and a second cross rod adjusting hole are formed in the length direction of the first cross rod and the second cross rod respectively. The threshing rib has the advantages that the corn threshing rate is raised; corn kernels are prevented from being damaged in the threshing process; safety performance is improved, and meanwhile the service life of a transmission belt is prolonged; refitting cost is low, and the threshing speed is raised.

Owner:重庆华楷农业科技有限公司

Threshing barrel

The invention discloses a threshing barrel. The threshing barrel comprises a rack and a first threshing bin, and the first threshing bin is arranged on the rack with the front high and the back low; braking wheels and an engine adjusting device are arranged at the bottom of the rack; the engine adjusting device comprises a first cross rod and a second cross rod, the first cross rod and the second cross rod are parallel to each other, and a first cross rod adjusting hole and a second cross rod adjusting hole are formed in the length direction of the first cross rod and the second cross rod respectively. The threshing barrel has the advantages that the corn threshing rate is raised; corn kernels are prevented from being damaged in the threshing process; safety performance is improve, and meanwhile the service life of a transmission belt is prolonged; refitting cost is low, and the threshing speed is raised.

Owner:重庆森鑫炬科技有限公司

Threshing machine with two threshing bins

InactiveCN105432247AAvoid damageExtended service lifeThreshersMechanical engineeringThreshing machine

The invention discloses a threshing machine with two threshing bins. The threshing machine comprises a rack and the first threshing bin which is arranged on the rack with the front part higher than the rear part. Braking wheels and an engine adjusting device are arranged at the bottom of the rack. The engine adjusting device comprises a first transverse rod and a second transverse rod, wherein the first transverse rod and the second transverse rod are parallel to each other, and a first transverse rod adjusting hole and a second transverse rod adjusting hole are formed in the length direction of the first transverse rod and the length direction of the second transverse rod respectively. The threshing machine with the two threshing bins has the advantages that the threshing rate of corn is increased; corn grains are prevented from being damaged in the threshing process; the service life of a transmission belt is prolonged while safety performance is improved; the transformation cost is low, and the threshing speed is increased.

Owner:CHONGQING JINGMING AGRI TECH CO LTD

Corn threshing device

InactiveCN105409464ATransformation of Chen BenlowImprove threshing speedThreshersAgricultural engineeringCorn kernel

The present invention discloses a corn threshing device. The corn threshing device comprises a rack and a first threshing chamber, wherein the first threshing chamber which is inclined forward upward is arranged on the rack; brake wheels are arranged on the bottom of the rack; a first feed port is formed above the front end of the first threshing chamber, and a first discharge port is formed in the rear end of the first threshing chamber; the rack is provided with a second threshing chamber, the second threshing chamber is positioned under the first threshing chamber, the second threshing chamber which is inclined forward downward is arranged on the rack, the high end of the second threshing chamber is a second feed port, and the second feed port is connected to the first feed port via the corn threshing chamber; and a second discharge port is formed in the lower end of the second threshing chamber, wherein a splash-proof device is arranged at the second discharge port. The corn threshing device disclosed by the present invention has the advantages that the corn removal rate is increased; the corn kernels are prevented from being destroyed in the threshing process; and the service life of the drive belt is prolonged while the safety performance is improved. The corn threshing device has the beneficial effects of low modification cost, high threshing velocity and the like.

Owner:CHONGQING HONGWEI MOLD DESIGN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com