Specific corn threshing machine

A special corn threshing machine technology, applied in threshing equipment, applications, agricultural machinery and tools, etc., can solve the problems of low threshing rate and affecting threshing efficiency, so as to improve the threshing rate, increase the threshing speed, and transform Chen Ben low effect

Inactive Publication Date: 2016-03-02

CHONGQING YINGENG ECOLOGICAL AGRI DEV CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, there is still a low threshing rate, and usually a second threshing is required to thresh all the corn kernels on the corn cob, which affects the threshing efficiency. On the other hand, the power device installed on the threshing machine cannot be adjusted. make it limited

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach

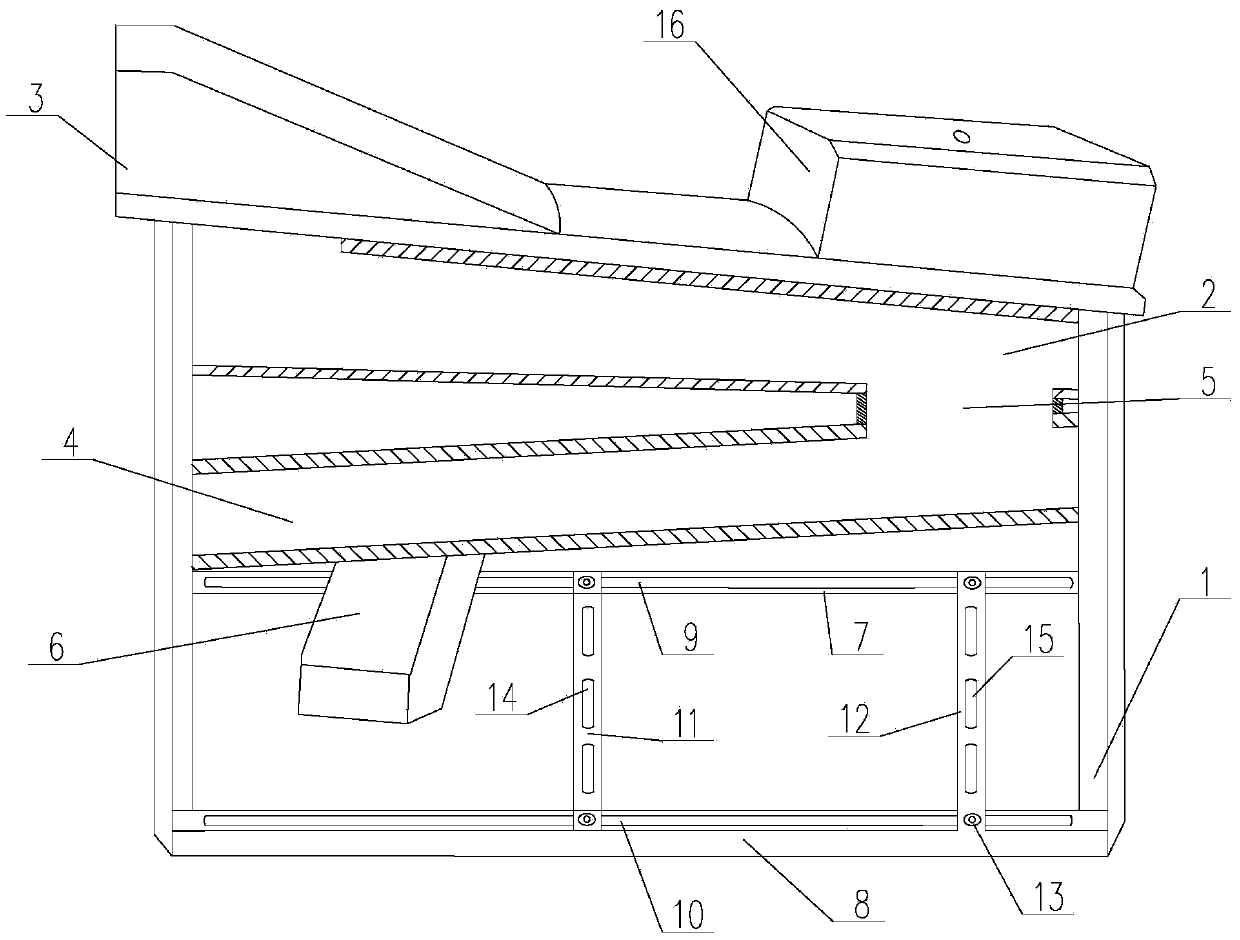

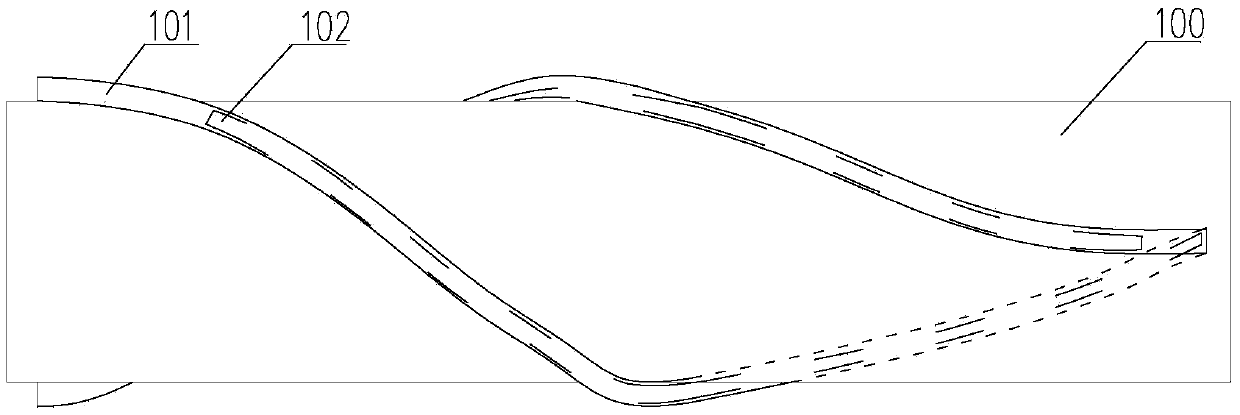

[0024] When in use, put the corn cobs from the first feeding port 3, the threshing drum 100 in the first threshing bin 2 starts to rotate, the corn cobs are threshed in the first threshing bin 2, and then the corn cobs pass through the corn threshing bin 5 into the second threshing bin 4 for the second threshing. After the threshing is completed, the corn kernels fall into the container through the splash guard 6.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a specific corn threshing machine comprising a rack and a first threshing cabin. The first threshing cabin is arranged on the rack with the front part higher than the back part; a threshing rolling cylinder is disposed in the first threshing cabin; a first inlet port is arranged over the front end of the first threshing cabin; a first outlet port is formed in the back end of the first threshing cabin; the rack is provided with a second threshing cabin; the second threshing cabin is arranged right under the first threshing cabin; the second threshing cabin is arranged on the rack with the front part lower than the back part; a high end of the second threshing cabin is provided with a second inlet port; the second inlet port is connected with the first outlet port via a corn threshing connection cabin; a low end of the second threshing cabin is provided with a second outlet port; and the second outlet port part is provided with an anti-splashing device. By the use of the specific corn threshing machine, corn threshing performance can be improved; and the specific corn threshing machine has beneficial effects of low transformation cost and high threshing speed.

Description

technical field [0001] The invention relates to an agricultural equipment, in particular to a thresher. Background technique [0002] The existing corn thresher comprises a threshing drum, a threshing bin and a frame, and the drum of the corn thresher is installed in the threshing bin and can rotate relative to the threshing bin. In order to improve the threshing efficiency, the drum of the existing threshing machine is generally provided with threshing ribs, and when the drum rotates, the corn kernels are separated from the corn cob under the action of the threshing ribs. However, there is still a low threshing rate, and usually a second threshing is required to thresh all the corn kernels on the corn cob, which affects the threshing efficiency. On the other hand, the power unit installed on the thresher cannot be adjusted. make it limited. [0003] Therefore those skilled in the art are devoted to developing a kind of threshing machine that improves cleaning rate. Cont...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A01F11/06

Inventor 张桂英苏黎辉李祖梅

Owner CHONGQING YINGENG ECOLOGICAL AGRI DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com