Corn kernel stripper for corn threshing

A stripping device and corn threshing technology, applied in the field of agricultural machinery, can solve the problems of time-consuming and laborious, low work efficiency, poor threshing effect, etc., and achieve good threshing effect, improve threshing speed, and accelerate shedding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

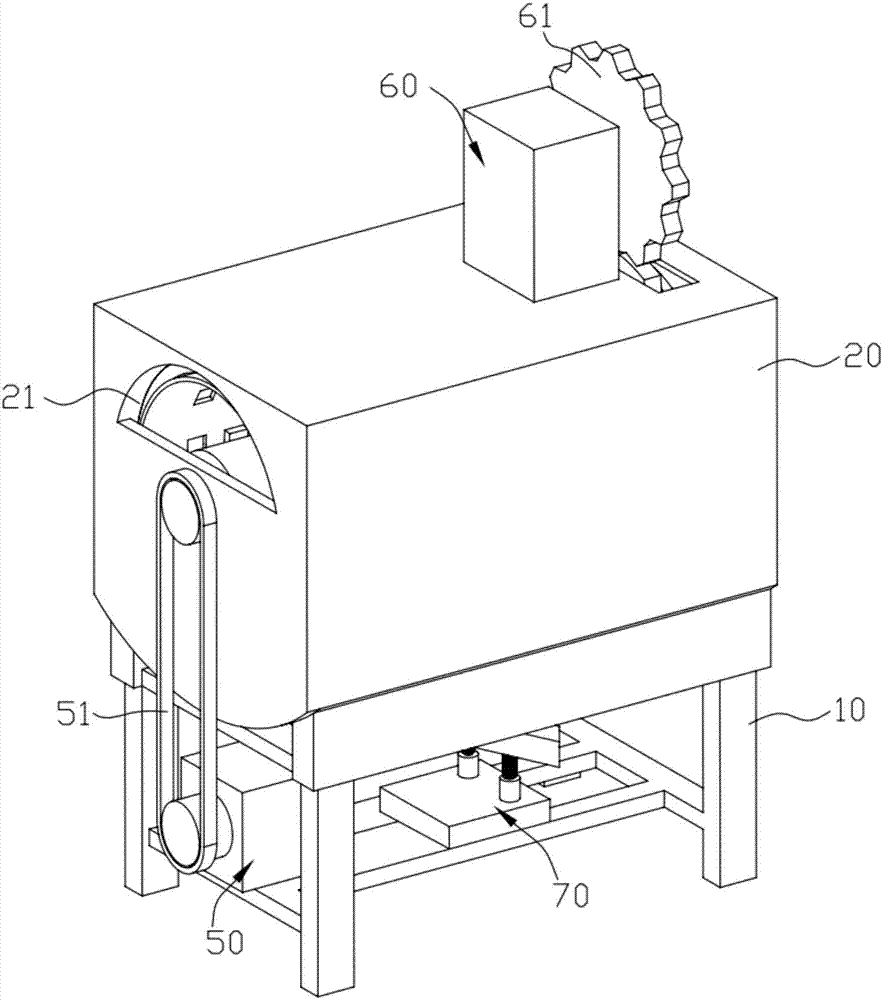

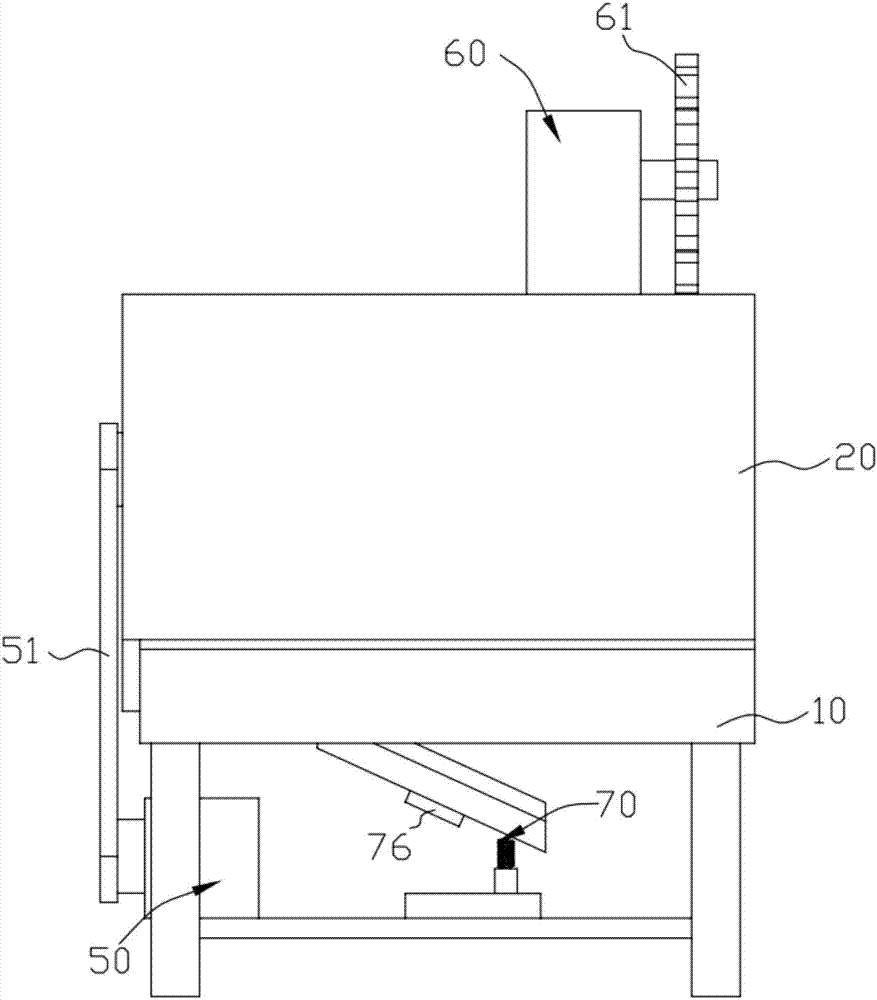

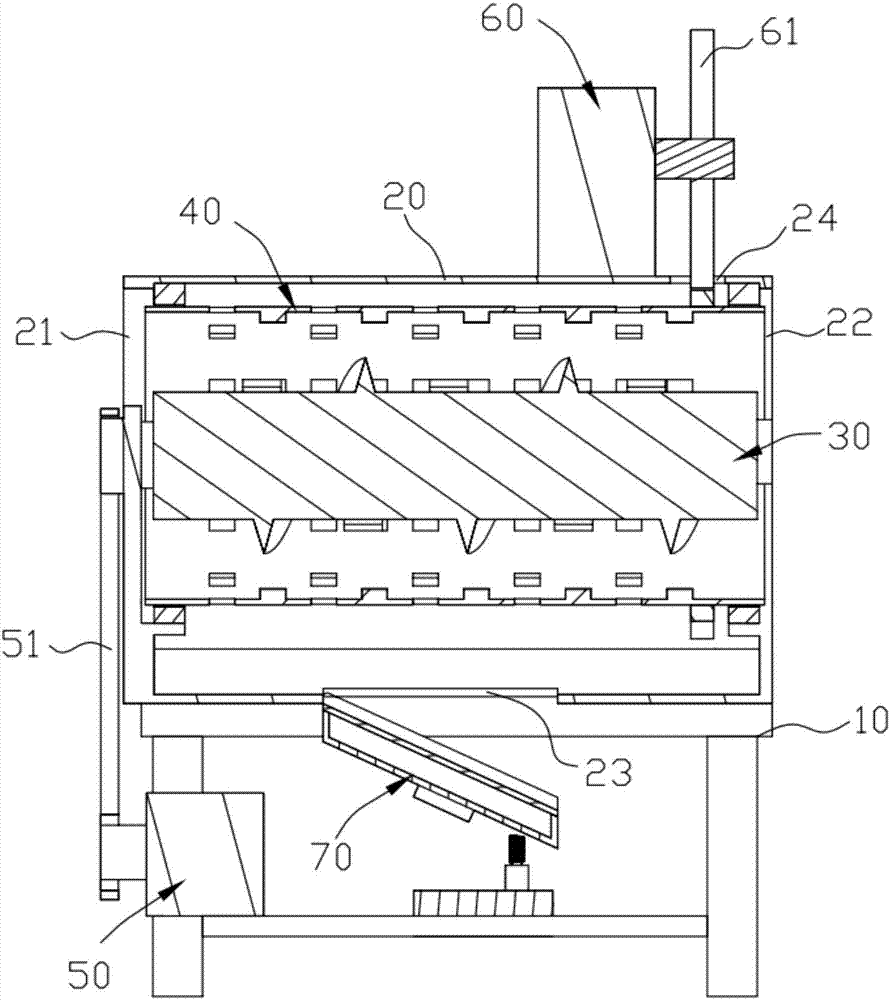

[0023] like Figure 1 to Figure 3 As shown, the present invention provides a corn kernel peeling device for corn threshing, including: a hollow box 20 fixedly arranged above the support frame 10, a first threshing roller rotatably arranged in the hollow cavity of the box 20 30 and the second threshing roller 40, installed on the support frame 10 for driving the first driving motor 50 of the first threshing roller 30 to rotate, installed on the top of the box 20 for driving the second threshing roller The roller 40 is rotated by the second drive motor 60 . Wherein, the box body 20 has a feed inlet 21, a rod core outlet 22 and a corn kernel outlet 23, and the corn kernel outlet 23 is formed on the bottom end surface of the box body 20; specifically, the box body The bottom en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com