Track self-running type cutting longitudinal flow full-feeding combine harvester

A combine harvester, cutting and vertical flow technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of decreased cleaning cleaning rate, large broken grain rate, increased cleaning loss rate, etc. The effect of increased threshing stroke, low rate of grain breakage, and low entrainment losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

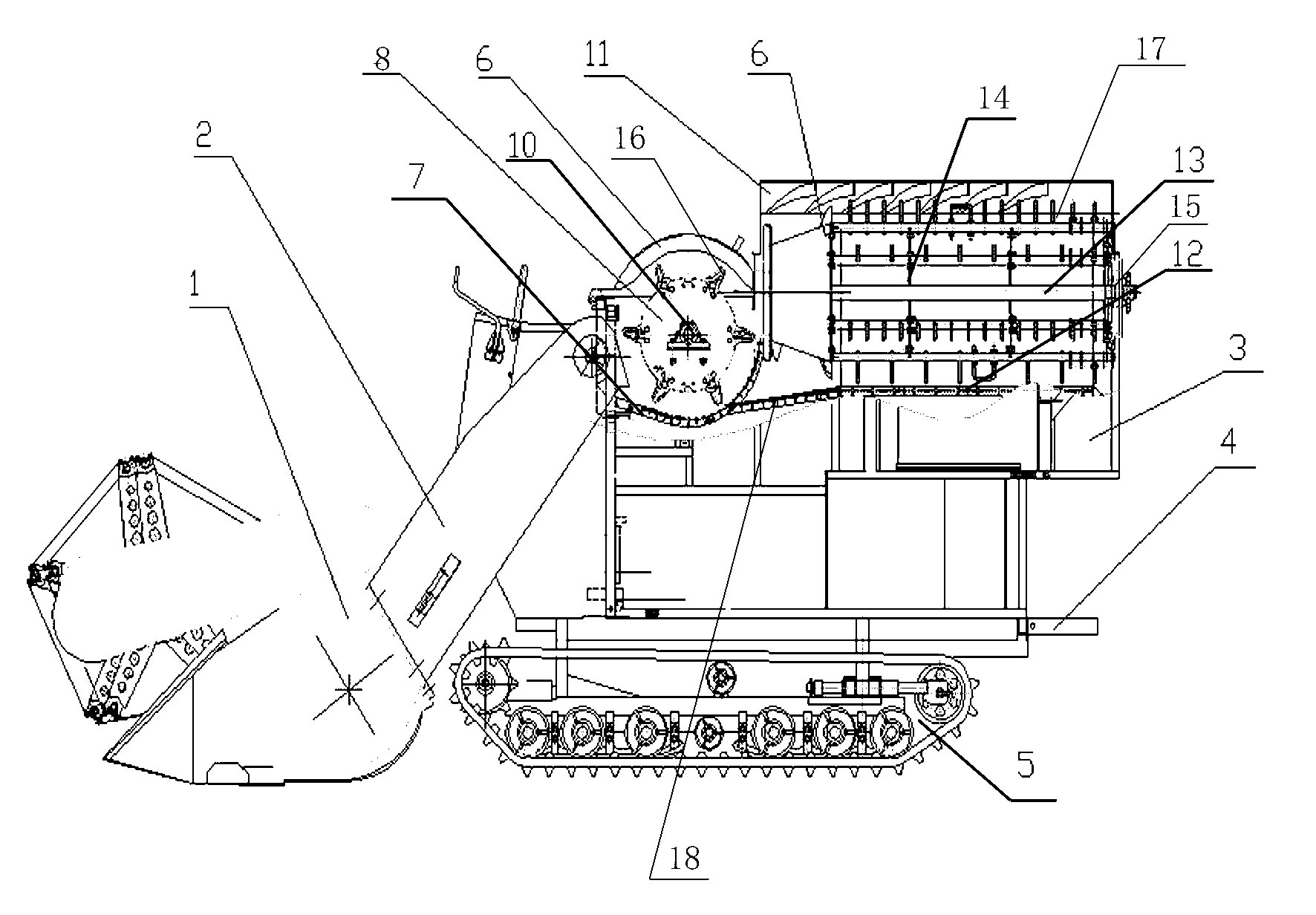

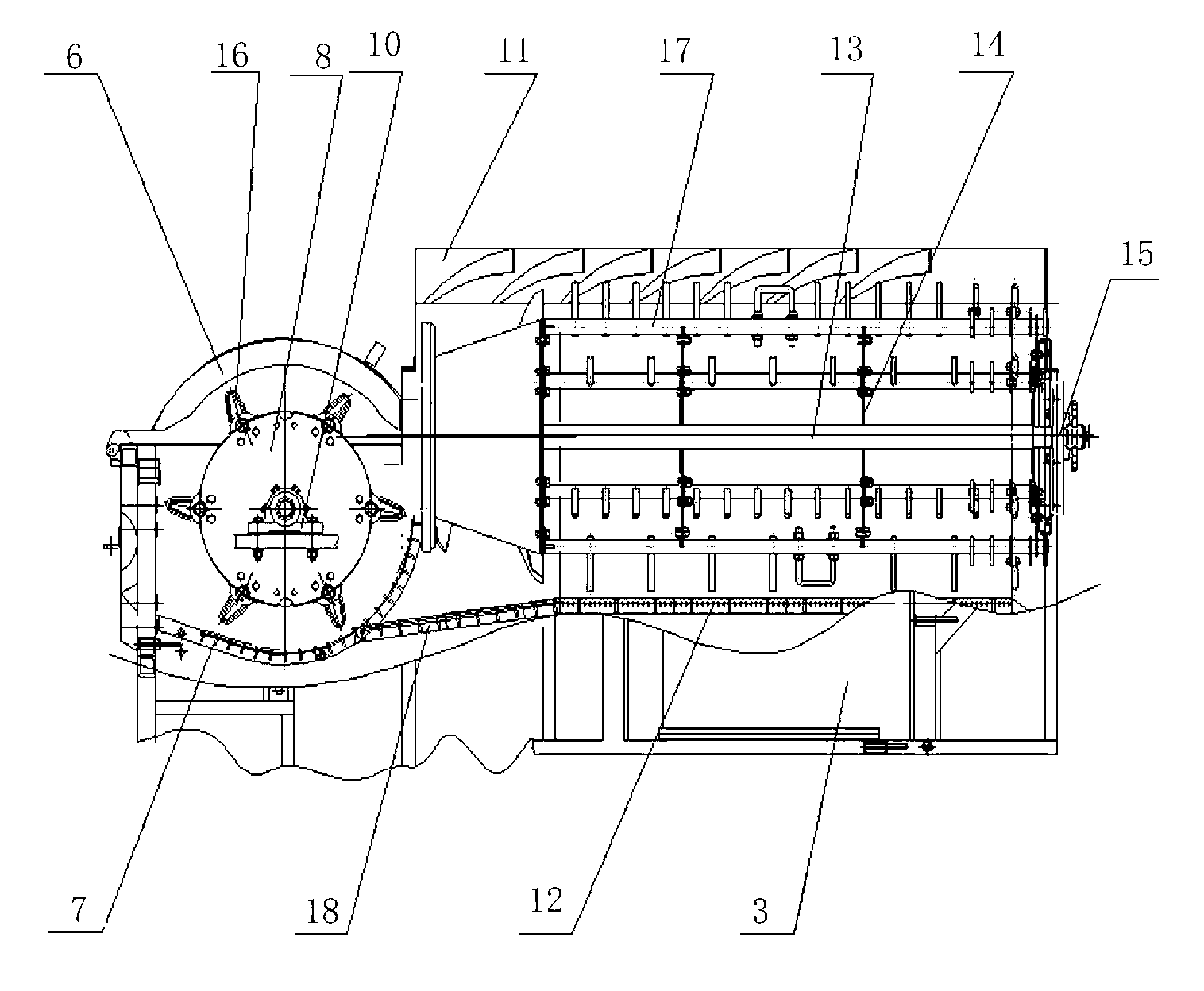

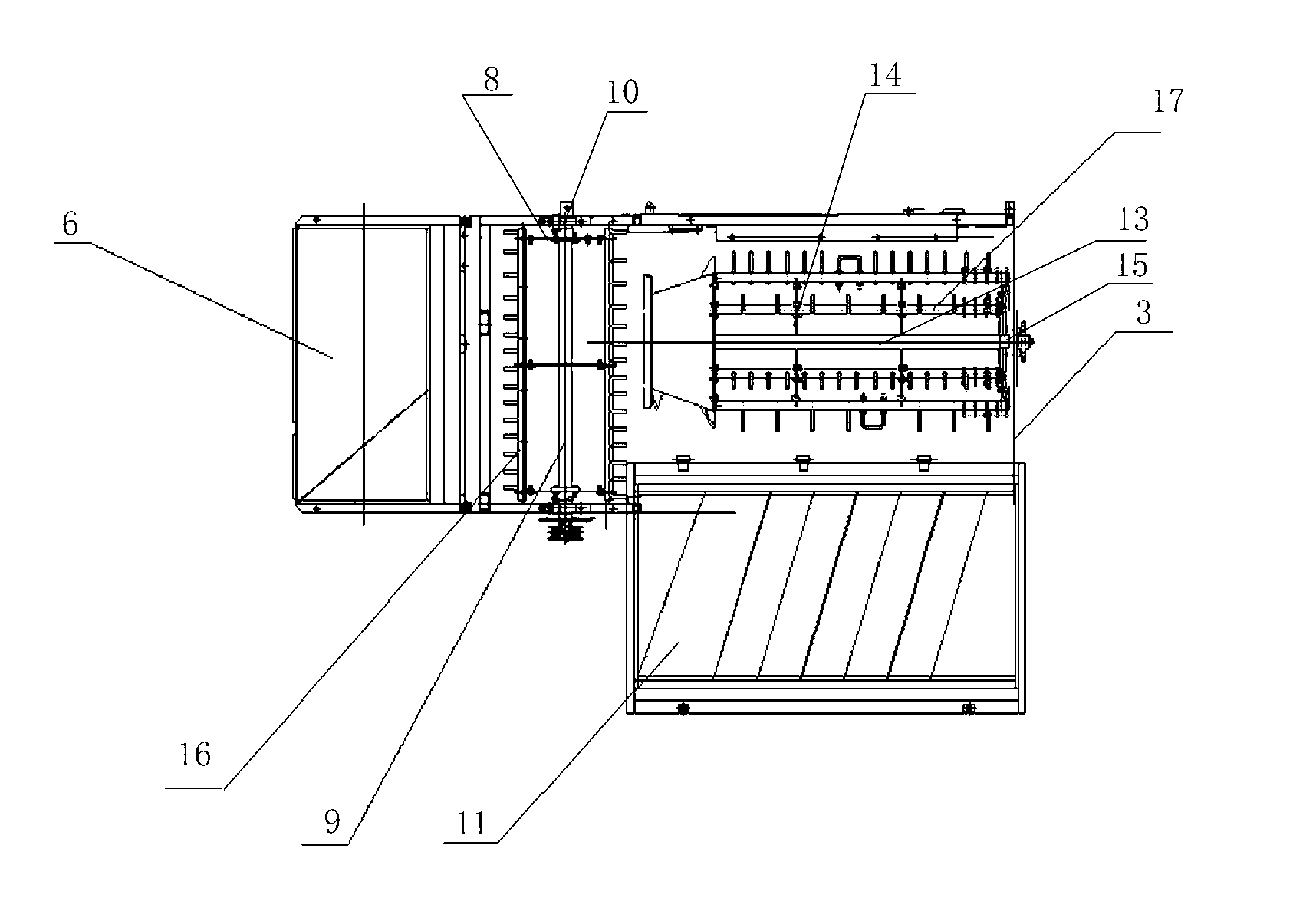

[0010] exist figure 1 , figure 2 with image 3 Among them, the present invention provides a crawler self-propelled cutting vertical flow full-feeding combine harvester, which sequentially includes a header 1, a conveying trough 2, a threshing drum assembly, a frame 3, a chassis 4 and a crawler belt from front to back. 5. The threshing roller assembly is located on the frame 3 and is supported by the frame 3. The frame 3 is located on the chassis 4, and the chassis 4 is located on the crawler belt 5. The threshing cylinder assembly includes a bow-shaped cutting flow threshing cylinder and nail teeth The vertical axial flow threshing drum, the bow-shaped tooth cutting flow threshing cylinder is arranged radially on the front part of the frame 3, and the top and bottom of the bow-shaped tooth cutting flow threshing cylinder are respectively provided with a cutting flow top cover 6 and a cutting flow gravure screen 7. Between the cutting-flow top cover 6 and the cutting-flow gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com