A threshing device for full-feed combine harvesting

A threshing device and full feeding technology, applied in the field of agricultural machinery, can solve problems such as affecting normal harvesting, unsmooth conveying, complex structure, etc., achieving the effect of simple and reliable structure, improving conveying and threshing capacity, and increasing separation area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific drawings.

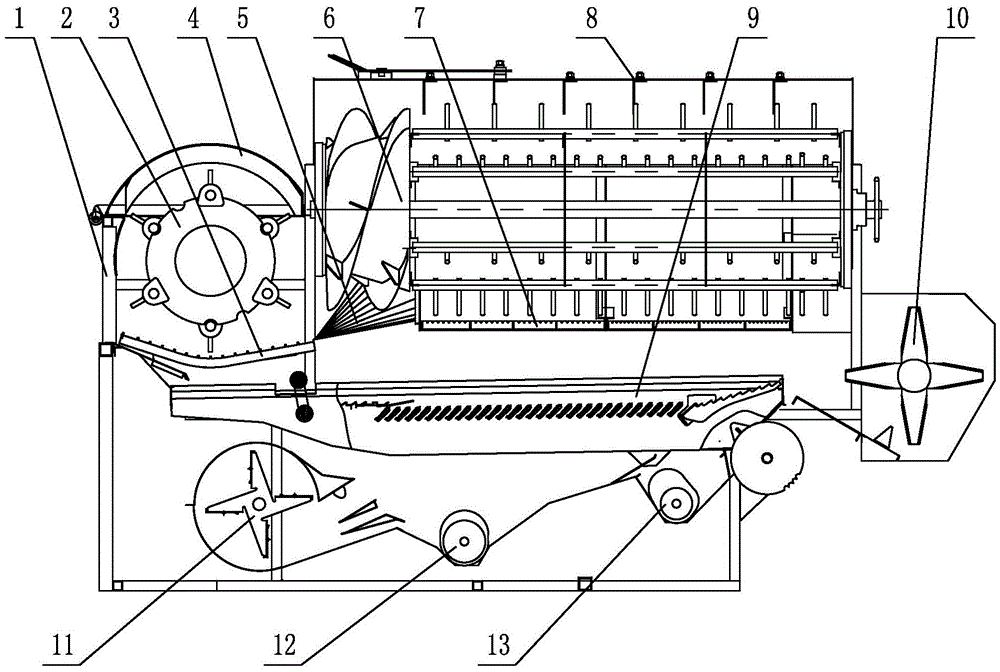

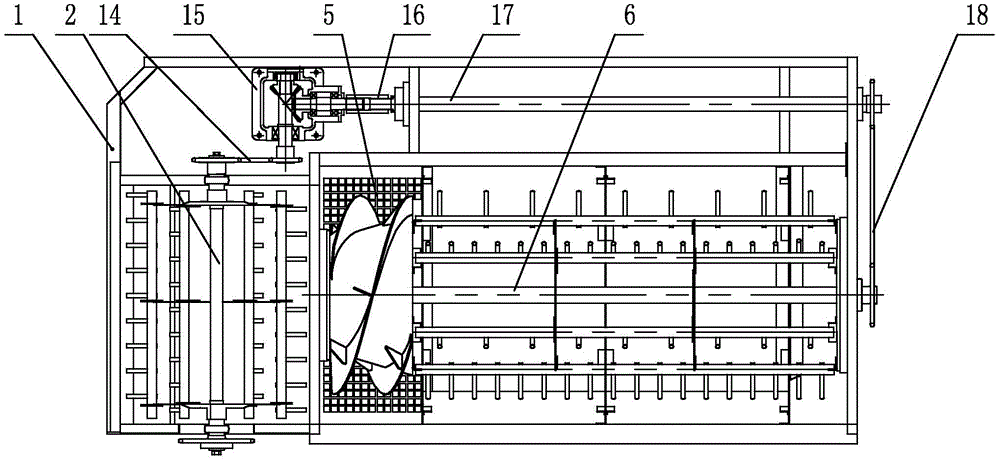

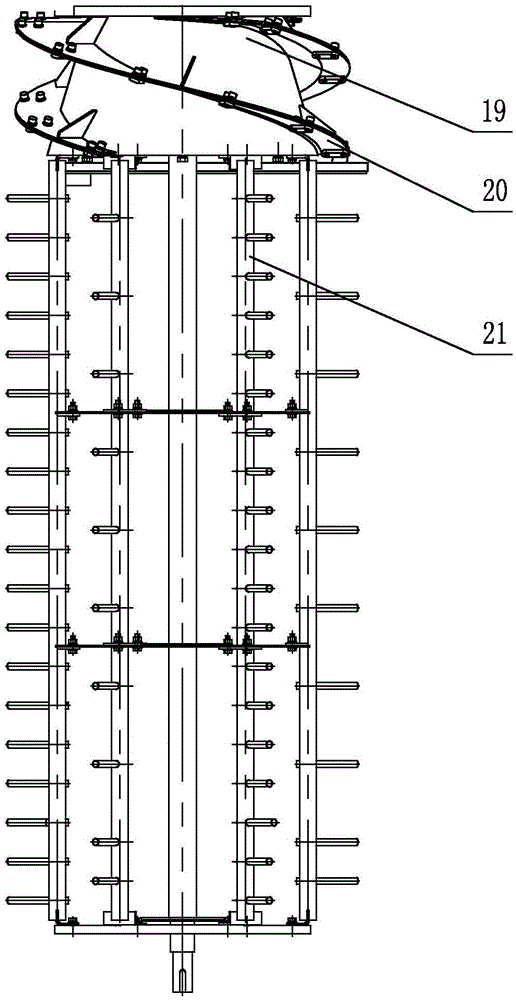

[0029] Such as Figure 1 to Figure 13 As shown: the threshing device for full-feeding combined harvesting includes a body 1, a front transverse cutting drum 2, a front grid concave screen 3, a front transverse cutting drum threshing chamber cover 4, a transition guide plate 5, a rear Longitudinal axial flow drum 6, rear grid concave screen 7, rear longitudinal axial flow drum threshing chamber cover 8, swing vibrating screen 9, stem chopping device 10, fan 11, primary auger 12, secondary auger 13. The first chain 14, the bevel gear transmission box 15, the transmission sleeve 16, the transmission shaft 17, the second chain 18, the feeding head 19, the wear-resistant blade 20, the threshing gear rod 21, the first helical blade 22, the second Spiral blade 23, third spiral blade 24, swing rod pin 25, swing rod 26, sieve body 27, eccentric wheel bearing seat 28, swing shaft 29, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com