A combined oil separation and recovery equipment

A combined equipment and oil separation technology, applied in the direction of grease/oily substance/float removal device, water/sludge/sewage treatment, liquid separation, etc. Large and other problems, to achieve the effect of small footprint, good water quality conditions, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

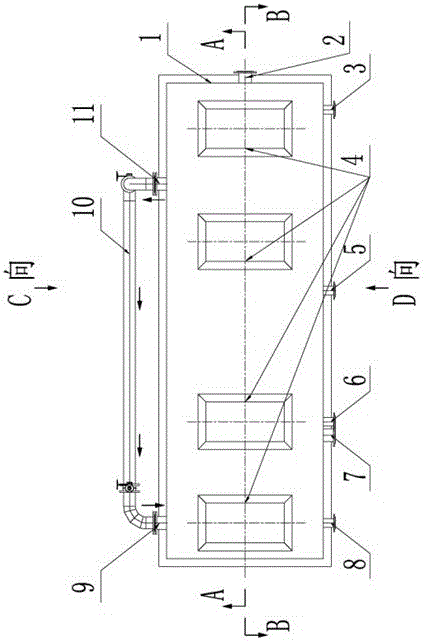

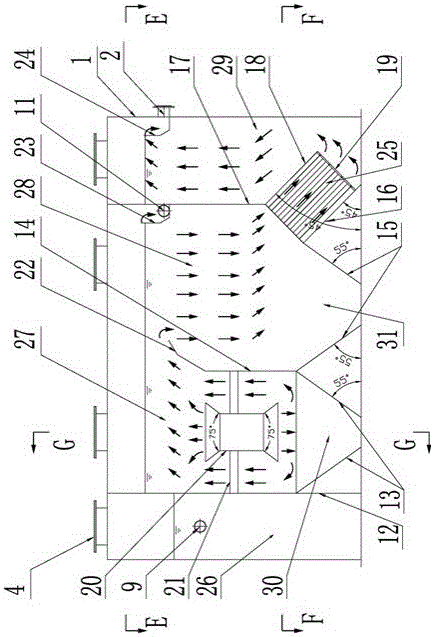

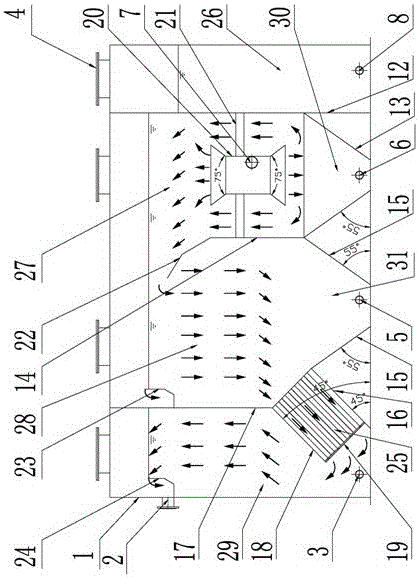

[0041] Such as Figure 1-7 As shown, a schematic diagram of a new type of oil separation combined equipment is provided for the technical solution of the patent of the present invention.

[0042] The sewage produced by an enterprise contains a large amount of heavy oil, slick oil, and partially dispersed light oil substances. If the oil substances enter the subsequent biochemical treatment system without treatment, they will adhere to the surface of the activated sludge and inhibit the growth of microorganisms in the biochemical treatment unit. Normal growth will directly affect the operation of the biochemical system. In severe cases, it will destroy the sludge activity of the activated sludge system and affect the effect of biochemical treatment. Oil separation pretreatment is required for this oily sewage.

[0043] The equipment includes four unit parts: primary oil separation and recovery chamber 27, secondary oil separation and recovery chamber 28, oil collection chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com