Lime powder calcination device

A lime powder and powder technology, applied in the field of rotary kiln, can solve the problems of unqualified quality, insufficient preheating, serious raw burning, etc., and achieve the effects of stable product quality, full use of heat, and sufficient pre-decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

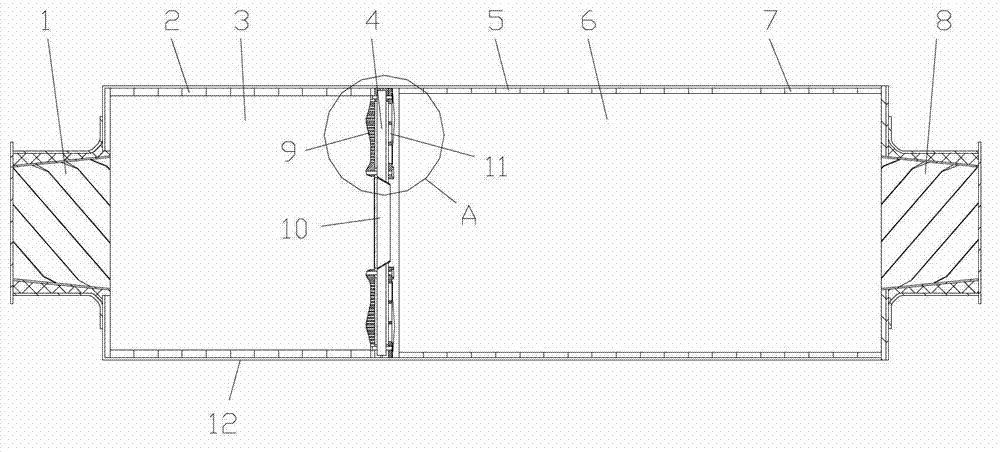

[0013] As shown in the drawings, the present invention includes a powder material preheater 1, a powder material rotary kiln 2, and a powder material cooler 4. The upper part of the powder preheater 1 is sealed and fixed with a powder feeding pipe 6 and an exhaust gas pipeline 7, the lower part is sealed and fixed with the left end of the powder rotary kiln 2, and the right end of the powder rotary kiln 2 is connected with the powder cooler 4. The left end is sealed and fixed, and there is a finished product discharge device 5 at the lower end of the finished product discharge port at the right end of the powder material cooler 4 . Since the powder material cooler 4 rotates continuously with the powder material rotary kiln 2, it continuously tumbles in the process of contacting with the cold air, fully cooling, and avoiding the characteristics of poor air permeability and insufficient cooling of the powder material below 3mm.

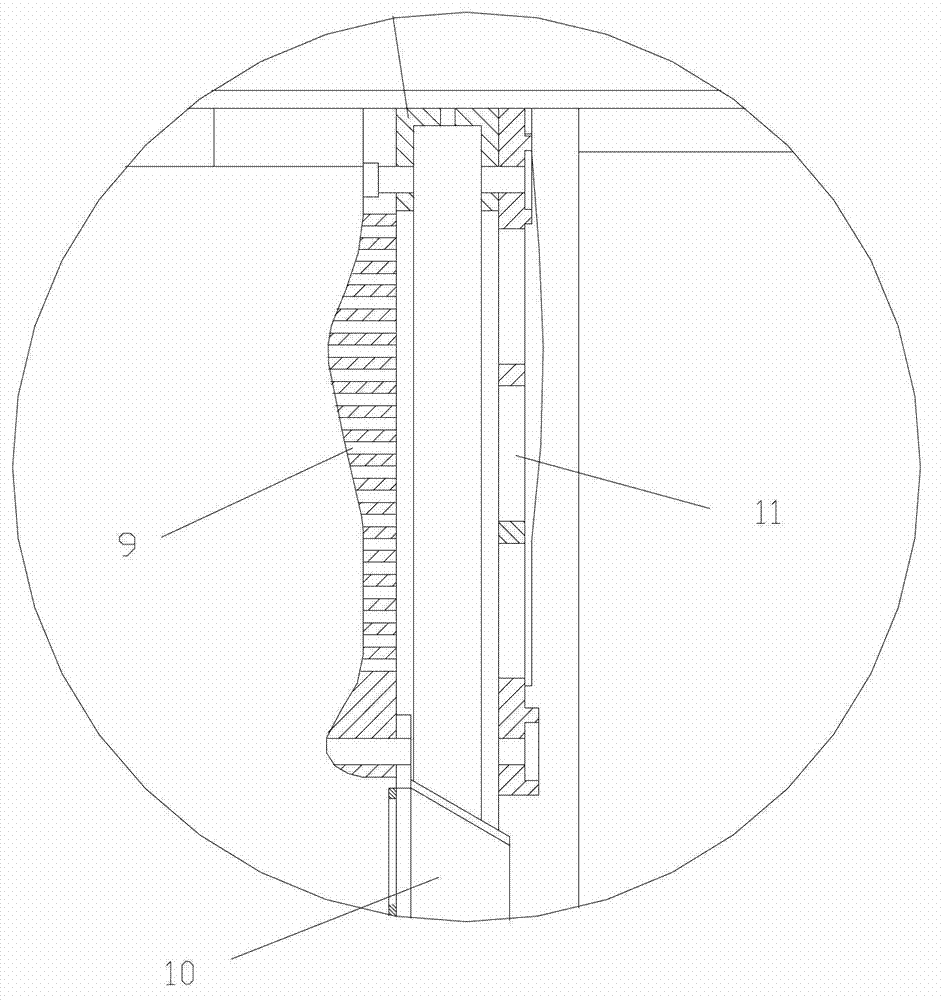

[0014] The powder preheater 1 is composed of a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com