Fluidized bed pump-out gas deoxidation and equipment thereof

A fluidized bed and fluidized bed reactor technology, applied in the direction of granular/powdered fuel gasification, combined combustion mitigation, etc., to achieve the effects of low cost, fast heat transfer rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

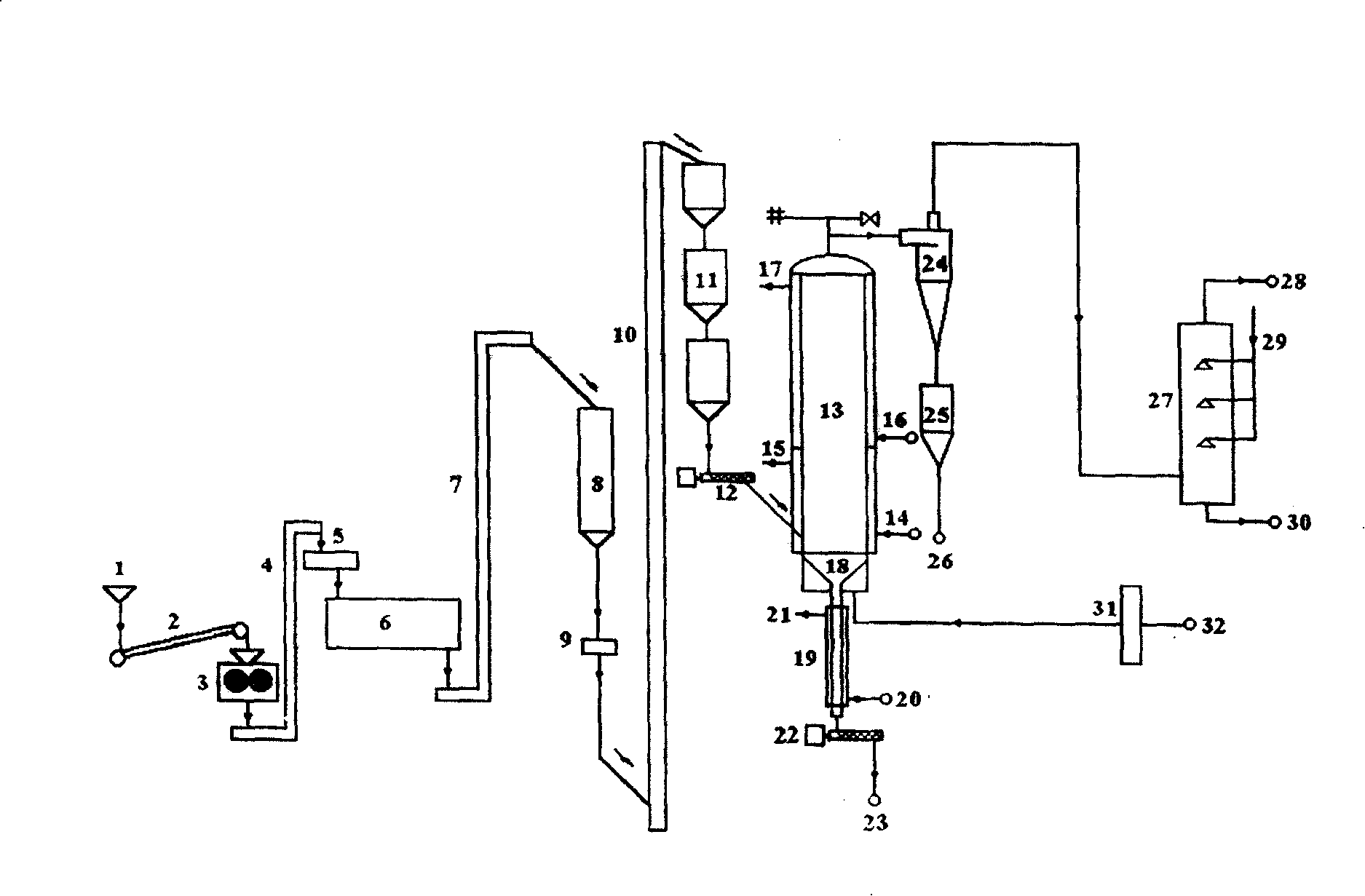

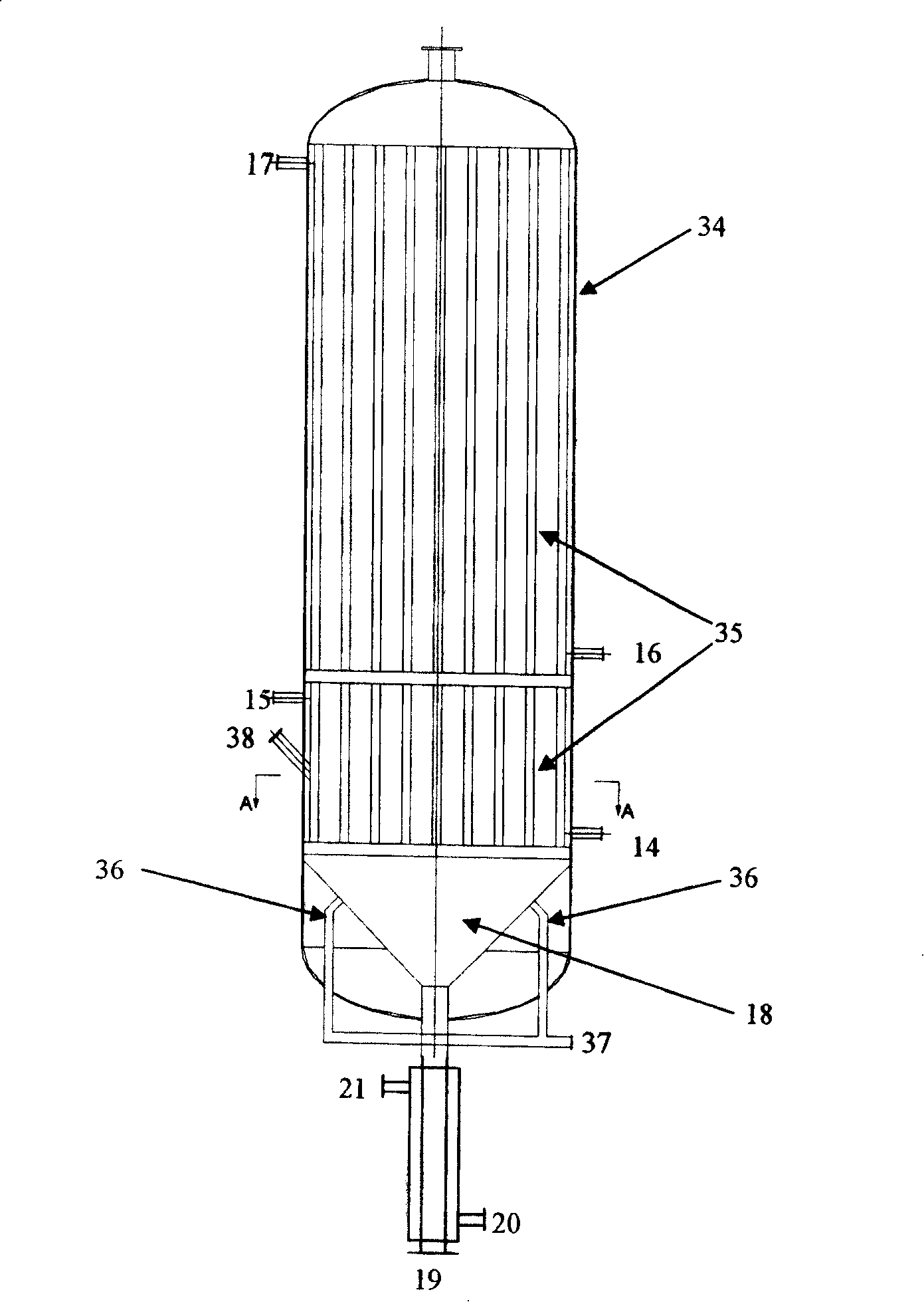

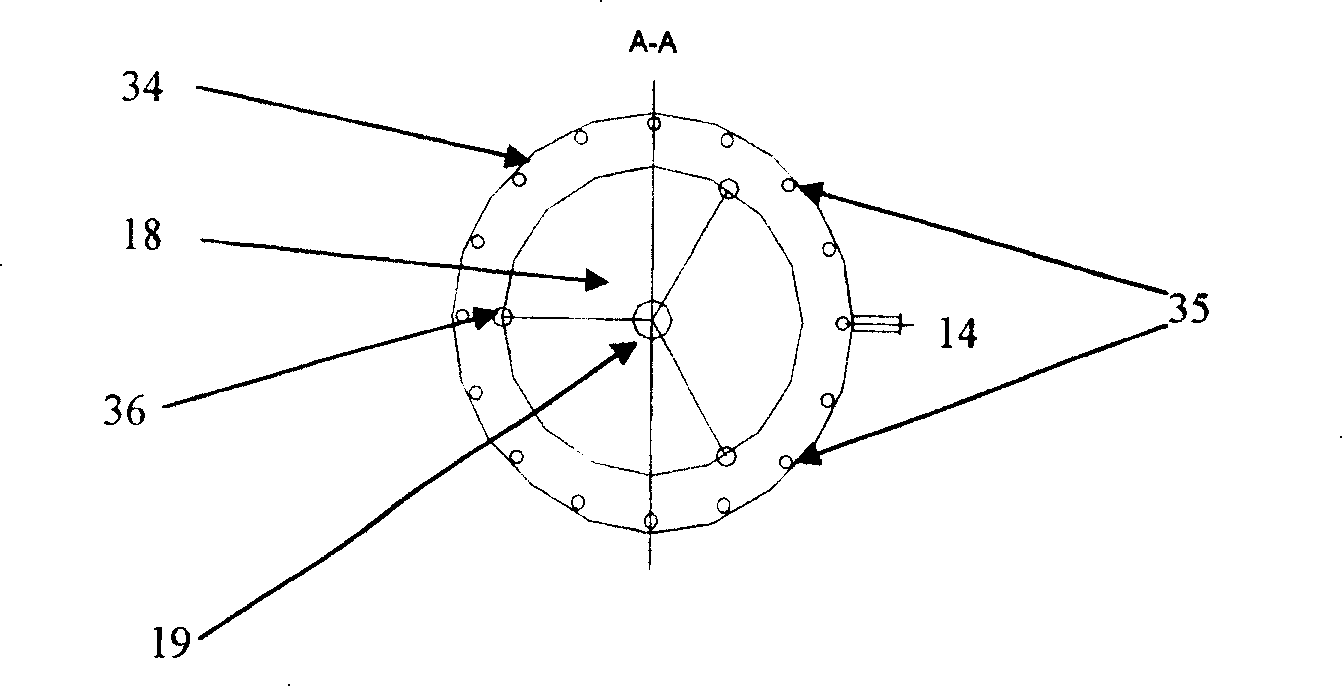

Method used

Image

Examples

Embodiment 1

[0020] Shanxian County Xinglong coal coke particles are used as deoxidizers, and the particle size is less than 8mm. The operating conditions are: temperature 400°C, pressure 0.1MPa (absolute pressure). The composition of the exhaust gas at the inlet is (volume percentage): CH 4 Content 50%, N 2 Content 40%, O 2 Content 10%. Firstly, put coke particles with a particle size of 3 , in the dense phase area at the bottom of the reactor 13, the coke particles are fluidized and fully mixed, and the oxygen in the exhaust gas and the coke undergo a partial oxidation reaction under the above temperature conditions. When the oxygen is consumed, heat is released to maintain the deoxidation reaction. Since the released heat is more than the heat required to maintain the deoxidation reaction, the remaining heat needs to be removed through the heat exchange pipe set 35 provided in the reactor, and the heat exchange rate is adjusted by controlling the heat exchange amount to maintain the ...

Embodiment 2

[0022] Coal coke particles from Bin County, Shaanxi Province were used as the deoxidizer, and the particle size, operating conditions, and inlet exhaust gas composition were the same as those in Example 1. After 8 hours of stable operation, there is no oxygen in the gas after water washing, CH 4 content nearly 50%, N 2 Content about 30.2%, CO 2 7.2% content, 3.6% CO content, also includes trace amount of H 2 .

Embodiment 3

[0024] Shan County Xinglong coal char particles were used as the deoxidizer, and the particle size and operating conditions were the same as in Example 1. The composition of the exhaust gas at the inlet is (volume percentage): CH 4 Content 70%, N 2 Content 24%, O 2 Content 6%. After 8 hours of stable operation, there is no oxygen in the gas after water washing, CH 4 Content 69.5%, N 2 Content about 23%, CO 2 content of 4.8%, CO content of 2.7%, also includes trace H 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com