High-stability integral titanium-silicalite-molecular-sieve catalyst and preparation method thereof

A titanium-silicon molecular sieve, high-stability technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficult diffusion of heat accumulation, low selectivity of main products, and poor catalyst stability. The effect of fast heat transfer, suppression of side reactions, and improvement of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

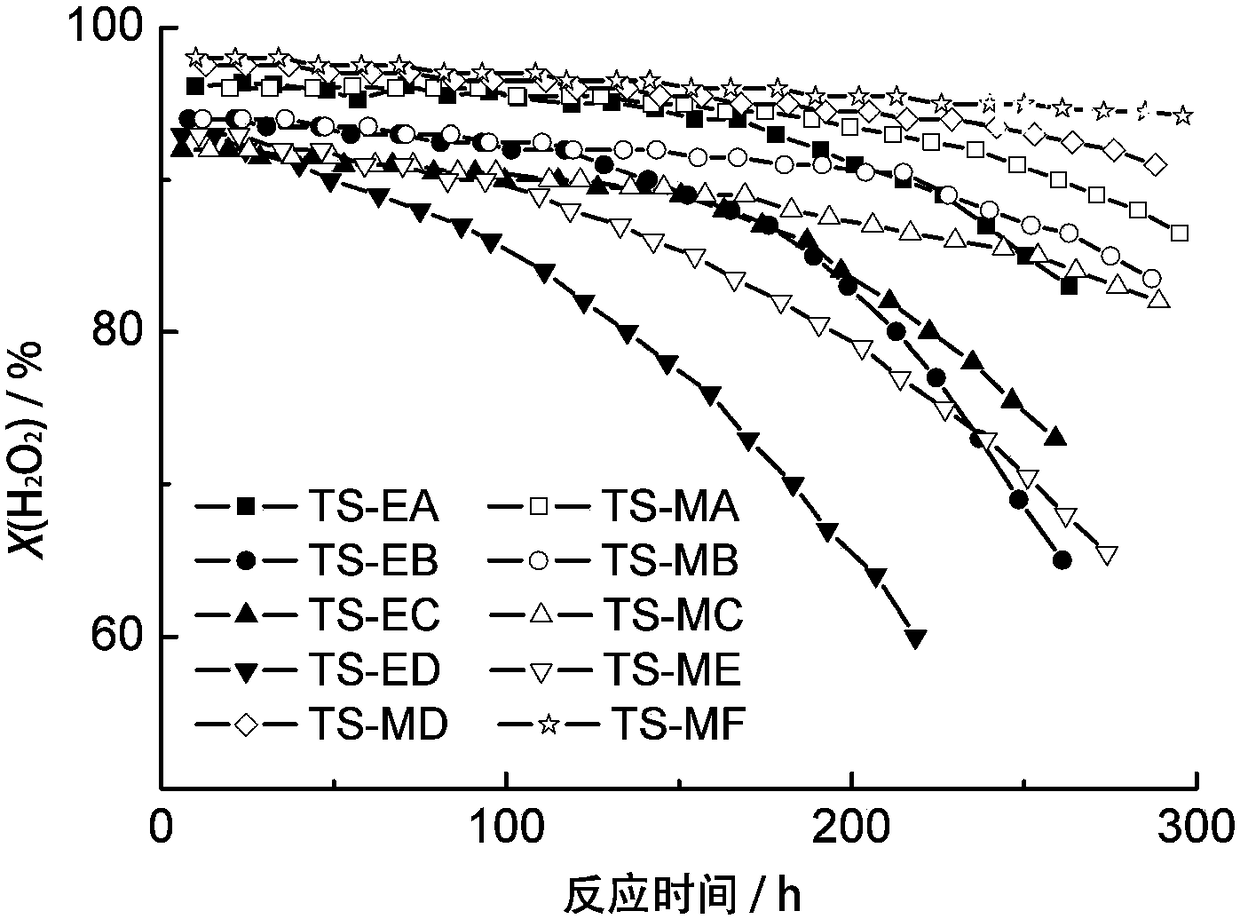

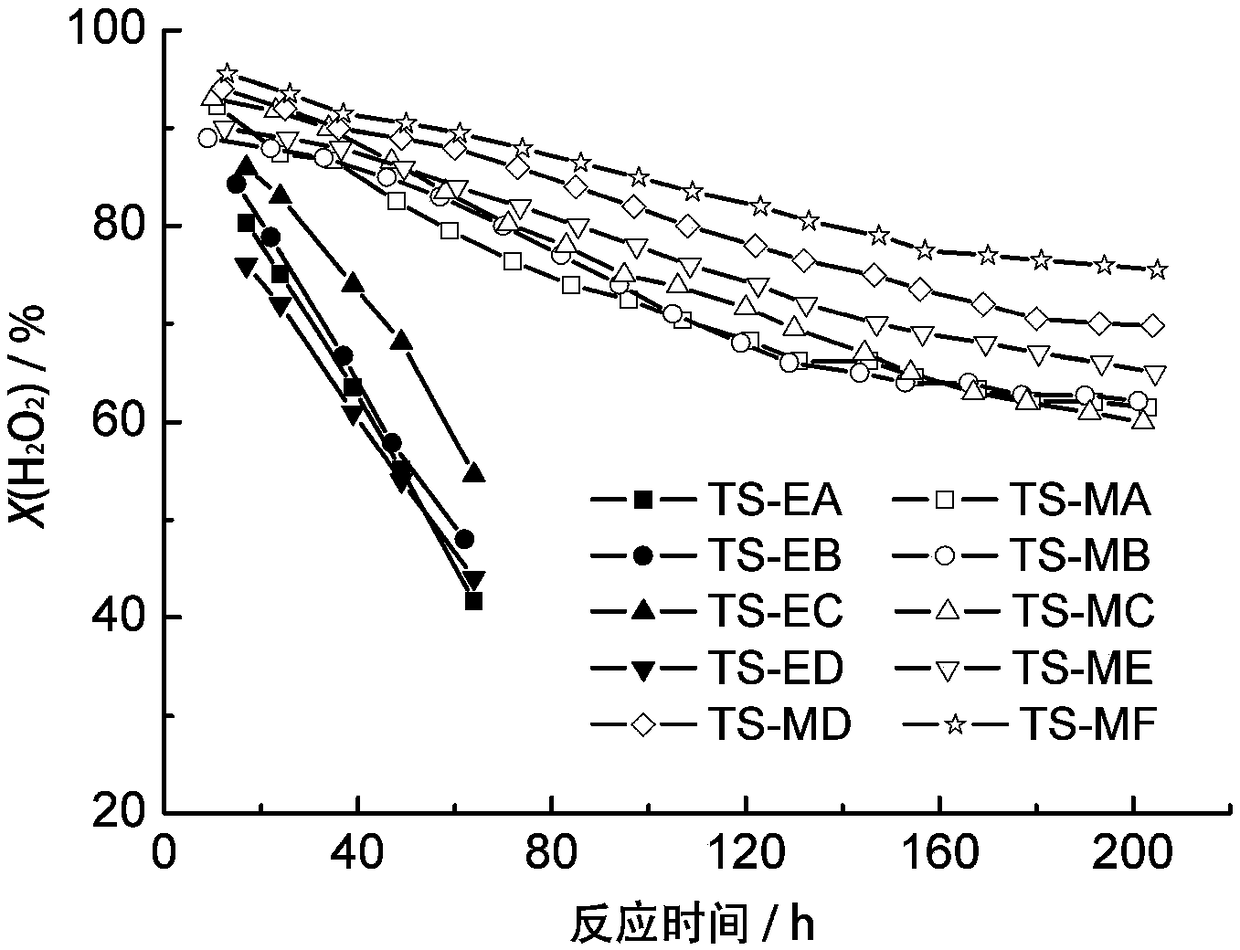

[0059] A stainless steel carrier with a cross-sectional diameter of 15mm, a height of 10cm, a porosity of 40 mesh, and a material of SUS316L was used. At 25°C, the carrier was soaked in 40% hydrofluoric acid for 24 hours, and then washed with deionized water until neutral; At 25°C, drop triethylenetetramine solution with a concentration of 50g / L into the pores of the carrier, so that each channel is filled with triethylenetetramine, put the carrier into a centrifuge, and centrifuge at a speed of 100r / min. 2min, take out the carrier; mix 10g of TS-PA powder prepared in Comparative Example 1 with 1.5g of polymethylacrylate, 10g of ethanol and 50g of water, stir evenly, and rotary evaporate at 40°C for 20min to obtain a viscous suspension. Add it dropwise into the above-mentioned treated carrier channels for coating treatment, put it in an oven at 80°C for 12 hours, take it out and bake it at 540°C for 5 hours to obtain a monolithic TS-1 catalyst, which is designated as TS-MA. Th...

Embodiment 2

[0061] The TS-PA powder in Example 1 was replaced with the TS-PB powder prepared in Comparative Example 2, and the other steps were the same as in Example 1, and the obtained monolithic TS-2 catalyst was designated as TS-MB. The coating thickness is 0.15mm.

Embodiment 3

[0063] The TS-PA powder in Example 1 was replaced with the TS-PC powder prepared in Comparative Example 3, and the other steps were the same as in Example 1, and the obtained monolithic Ti-MWW catalyst was designated as TS-MC. The coating thickness is 0.15mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com