External particle heat absorber and solar power generation system

An external heat absorber technology, applied in solar thermal power generation, solar heating systems, solar thermal energy, etc., can solve the problem of low heat absorption efficiency of particle heat absorbers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

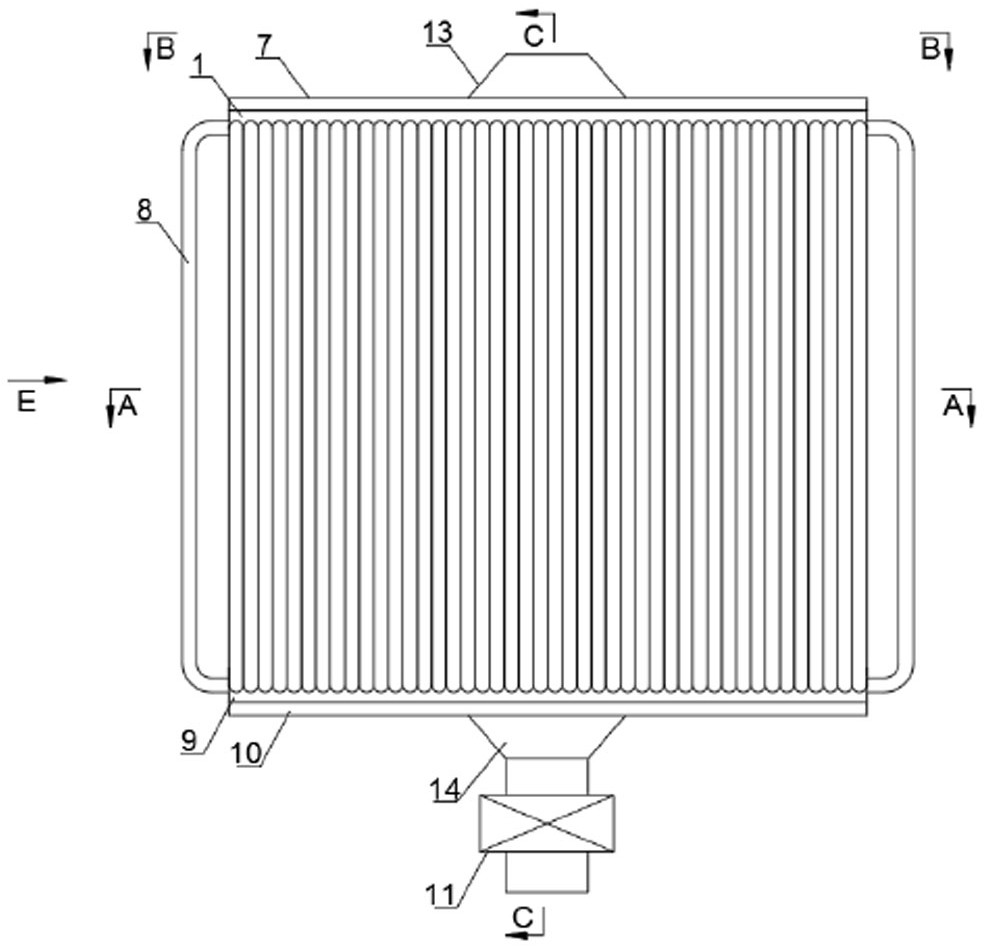

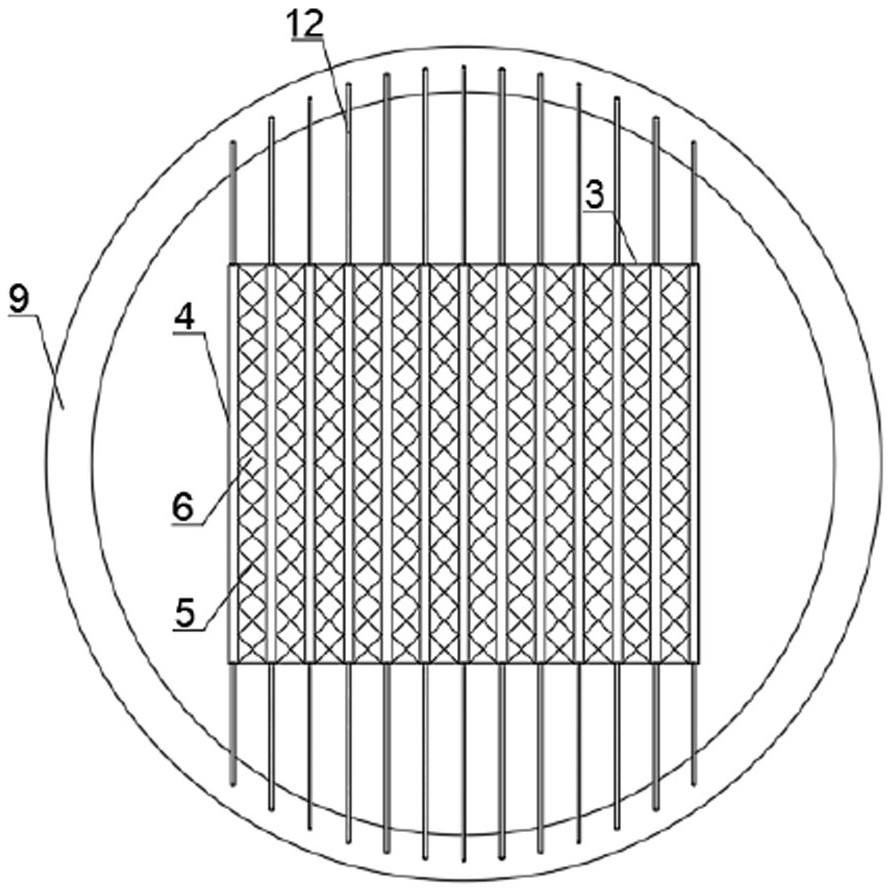

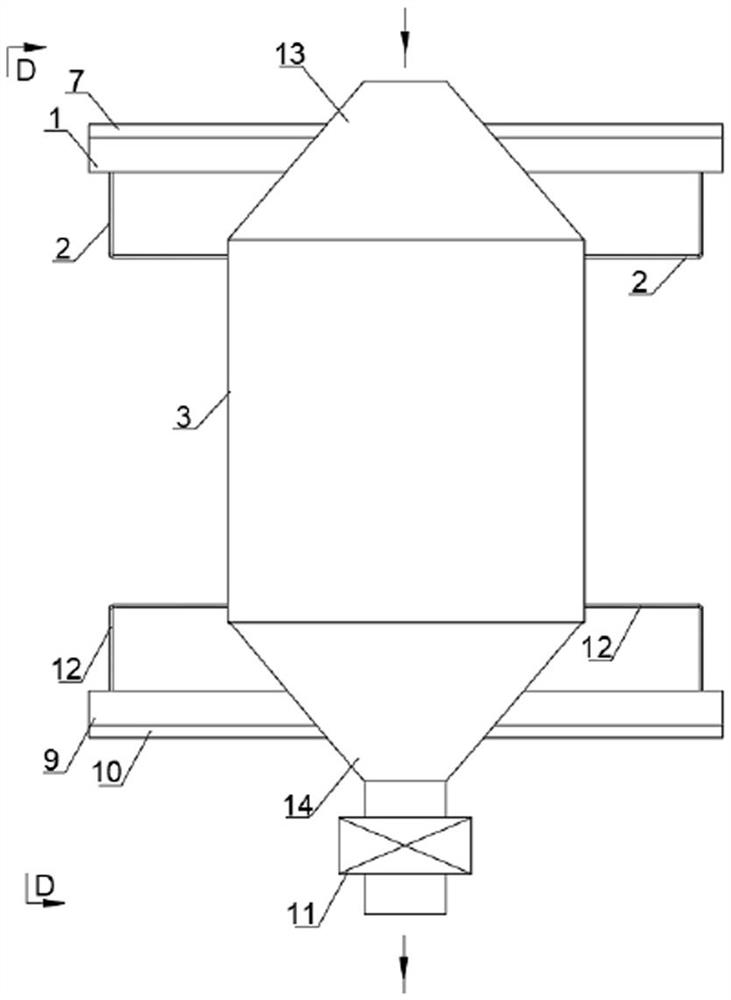

[0046] see Figure 1 to Figure 6, In one embodiment, an external particle heat absorber includes a particle heat exchanger 3 and a heat absorption tube group 8 for receiving solar energy. The particle heat exchanger 3 is provided with at least one particle channel 6 and at least one working medium channel 4, and the working medium channel 4 is in heat transfer contact with the particle channel 6, so that the particles in each particle channel 6 can be connected to the working medium channel The phase change working medium in 4 performs heat exchange. The heat-absorbing tube group 8 is filled with a phase-change working fluid whose evaporation temperature is higher than the heat-absorbing temperature of the particles circulating in the particle channel 6 . The output end of the heat-absorbing tube group 8 is connected with the input end of the working medium channel 4, and the input end of the heat-absorbing tube group 8 is connected with the output end of the working medium c...

Embodiment 2

[0072] A solar power generation system, comprising the external particle heat absorber in the first embodiment above. By setting the phase change working medium as the intermediate heat exchange medium, the heat is transferred to the particles after evaporation and the particles are raised to the required temperature, which has higher efficiency. At the same time, the external heat sink structure is adopted, which is conducive to the expansion of the installed capacity of the power station, thereby reducing the investment cost per unit scale. The external heat sink can be arranged in a circular mirror field to increase land utilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com