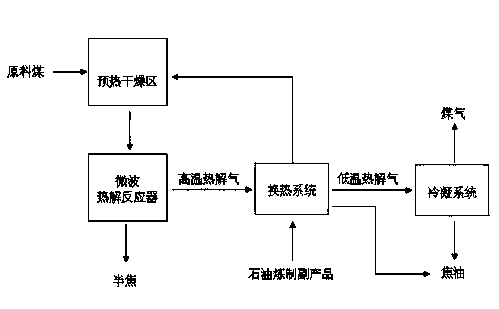

Combined process for co-pyrolysis of coal and petroleum refining by-product

A technology of petroleum refining and combined process, which is applied in the petroleum industry, coke oven, direct heating and dry distillation, etc., can solve the problems of low tar yield and long pyrolysis time, and achieve low economic benefit, low price and strong polarity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024]Jurassic coal (lignite) in a certain area in northern Shaanxi was selected, and its industrial analysis is shown in Table 1. The by-product of petroleum refining is RFCC oil slurry from a refinery. The physicochemical properties of RFCC oil slurry are shown in Table 2. According to the mass ratio of 3:7, the raw coal with a certain particle size (5-50mm) and the catalytic cracking oil slurry with a temperature of 250°C after heat exchange are fully mixed in the preheating drying zone, and the temperature of the mixture of raw coal and catalytic cracking oil slurry is is 150°C. The mixture of raw coal and catalytic cracking oil slurry is continuously fed into the microwave pyrolysis reactor at a rate of 100 g / min. The microwave frequency is 2450MHz, the pyrolysis temperature is stable at 650°C, and the carrier gas is nitrogen. The semi-coke generated by the pyrolysis reaction is collected after being cooled to normal temperature. The high-temperature gas generated by py...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com