Sewage treatment preparation and preparation method thereof

A technology for sewage treatment and preparation, applied in the field of water pollution control, can solve the problems of low adsorption performance, reduced magnetic properties and adsorption capacity, etc., and achieve the effects of high adsorption performance, increasing contact area, and improving sewage treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

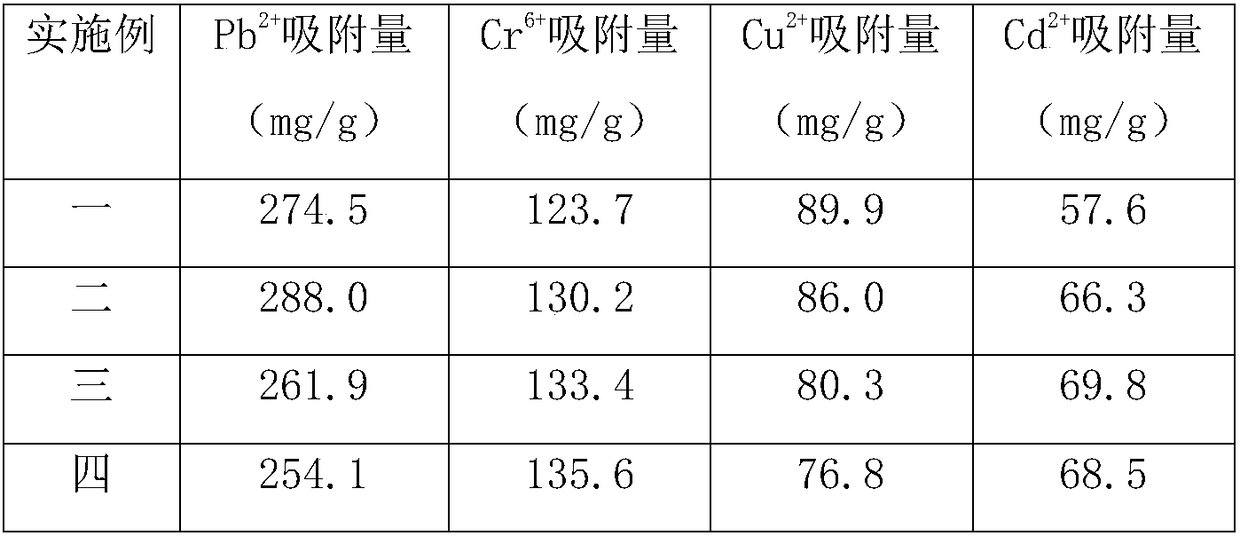

Examples

Embodiment 1

[0032] Preparation of ferroferric oxide: take the natural loofah to remove impurities, wash it with water, dry it, and keep the overall shape and structure of the loofah, and then place it in a plasma reactor with a nitrogen flow of 50sccm, a pressure of 3Pa, and a power of 60W Under the conditions, plasma treatment for 1min, take out the pretreated loofah; soak the pretreated loofah in a solution containing 0.2mol / LFeCl 2 4H 2O and 0.125mol / L FeCl 3 ·6H 2 In the mixed solution of O, after soaking for 15 hours, pass it into a nitrogen water bath to react for 1 hour, after vacuum drying at 100-120°C, place it in a tube furnace for calcination at 500°C for 2 hours, take it out with the furnace cooling, and obtain a porous mesh tetraoxide For three irons, the obtained ferric iron tetroxide is cut into small pieces and stored for subsequent use.

[0033] Preparation of modified biochar: Put the rice bran into a stainless steel pyrolysis device, blow in nitrogen gas to exhaust t...

Embodiment 2

[0038] Preparation of ferroferric oxide: take natural loofah to remove impurities, wash it with water, dry it, and keep the overall shape and structure of loofah, then place it in a plasma reactor, under nitrogen flow 80sccm, pressure 4Pa, power 80W Under the conditions, plasma treatment for 1min, take out the pretreated loofah; soak the pretreated loofah in a solution containing 0.2mol / LFeCl 2 4H 2 O and 0.125mol / L FeCl 3 ·6H 2 In the mixed solution of O, after soaking for 18 hours, pass it into a nitrogen water bath to react for 1.5 hours, after vacuum drying at 100-120°C, place it in a tube furnace for calcination at 550°C for 2 hours, take it out with the furnace cooling, and obtain a porous mesh tetra Ferric oxide, the obtained ferric oxide is cut into small pieces and stored for subsequent use.

[0039] Preparation of modified biochar: Mix rice bran and peanut shells in a mass ratio of 1:1 and put them into a stainless steel pyrolysis device, blow in nitrogen to exhau...

Embodiment 3

[0044] Preparation of ferroferric oxide: take natural loofah to remove impurities, wash it with water, dry it, and keep the overall shape and structure of loofah, then place it in a plasma reactor, under nitrogen flow 80sccm, pressure 4Pa, power 80W Under the conditions, plasma treatment 2min, take out the pretreated loofah; soak the pretreated loofah in a solution containing 0.2mol / LFeCl 2 4H 2 O and 0.125mol / L FeCl 3 ·6H 2 In the mixed solution of O, after soaking for 18 hours, pass it into a nitrogen water bath to react for 1.5 hours, after vacuum drying at 100-120°C, place it in a tube furnace for calcination at 600°C for 2 hours, take it out with the furnace cooling, and obtain a porous mesh tetra Ferric oxide, the obtained ferric oxide is cut into small pieces and stored for subsequent use.

[0045] Preparation of modified biochar: put rice bran, peanut shells, and corncobs into a stainless steel pyrolysis device at a mass ratio of 1:2:2, pass in nitrogen to exhaust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com