Preparation method of Cu2O-CuO composite oxide

A composite oxide, cu2o-cuo technology, applied in the preparation of microspheres, copper oxide/copper hydroxide, microcapsule preparations, etc., can solve the problems of increasing production costs, environmental loads, complex multi-step operations, etc., and achieve easy operation. , the preparation process is simple, the effect of mild synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

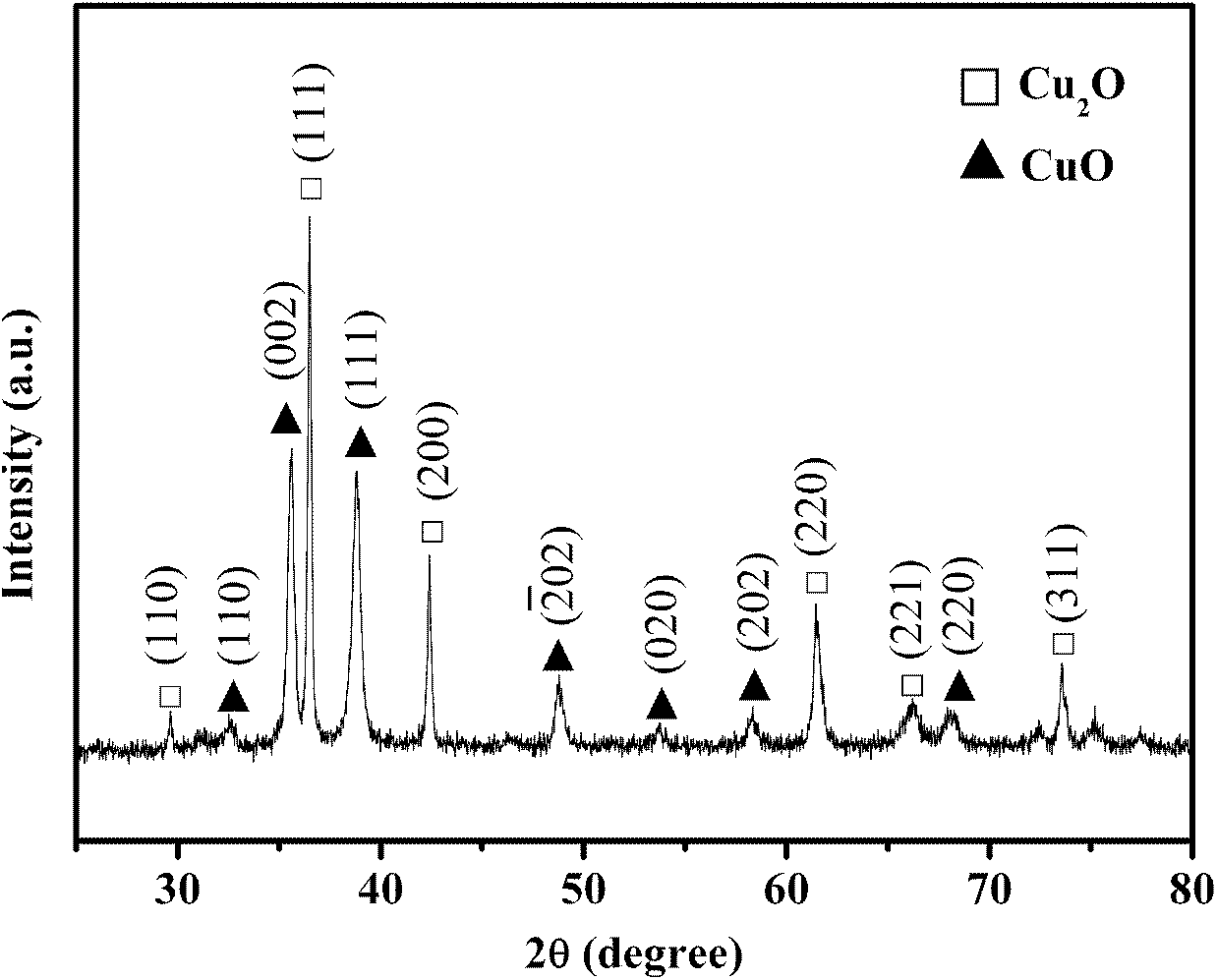

[0020] Use a pipette to pipette 8mL of 0.36mmol / L glucose solution into a 50mL polytetrafluoro-lined hydrothermal kettle, then put 1.0mmol basic copper carbonate powder into the above hydrothermal kettle, and use a glass rod to After stirring evenly, tighten and seal the hydrothermal kettle, place it in an oven at 190°C, and after reacting for 20 hours, wash the product obtained by the reaction with distilled water for 3 to 5 times, centrifuge and dry at room temperature at 20°C for 24 hours to obtain the size Cu assembled into nanosheets of 3-5 μm 2 O-CuO composite oxide. The SEM characterization of the synthesized complex was as follows figure 1 shown by figure 2 The XRD crystal structure shown shows that the synthesized product is Cu 2 O-CuO composite oxide.

Embodiment 2

[0022] Use a pipette to pipette 8mL of 0.06mmol / L glucose solution into a 50mL polytetrafluoro-lined hydrothermal kettle, then put 1.0mmol basic copper carbonate powder into the above hydrothermal kettle, and use a glass rod to After stirring evenly, tighten and seal the hydrothermal kettle, place it in an oven at 160°C, and after reacting for 5 hours, wash the product obtained by the reaction with distilled water for 3 to 5 times, centrifuge and dry at room temperature at 15°C for 10 hours to obtain the size Cu assembled into nanosheets of 2.5-4 μm 2 O-CuO composite oxide.

Embodiment 3

[0024] Use a pipette to pipette 8mL of 0.60mmol / L glucose solution into a 50mL polytetrafluoro-lined hydrothermal kettle, then put 1.0mmol basic copper carbonate powder into the above hydrothermal kettle, and use a glass rod to After stirring evenly, tighten and seal the hydrothermal kettle, place it in an oven at 220°C, and after reacting for 10 hours, wash the product obtained by the reaction with distilled water for 3 to 5 times, centrifuge and dry at room temperature at 30°C for 20 hours to obtain the size Cu 2 O-CuO composite oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com