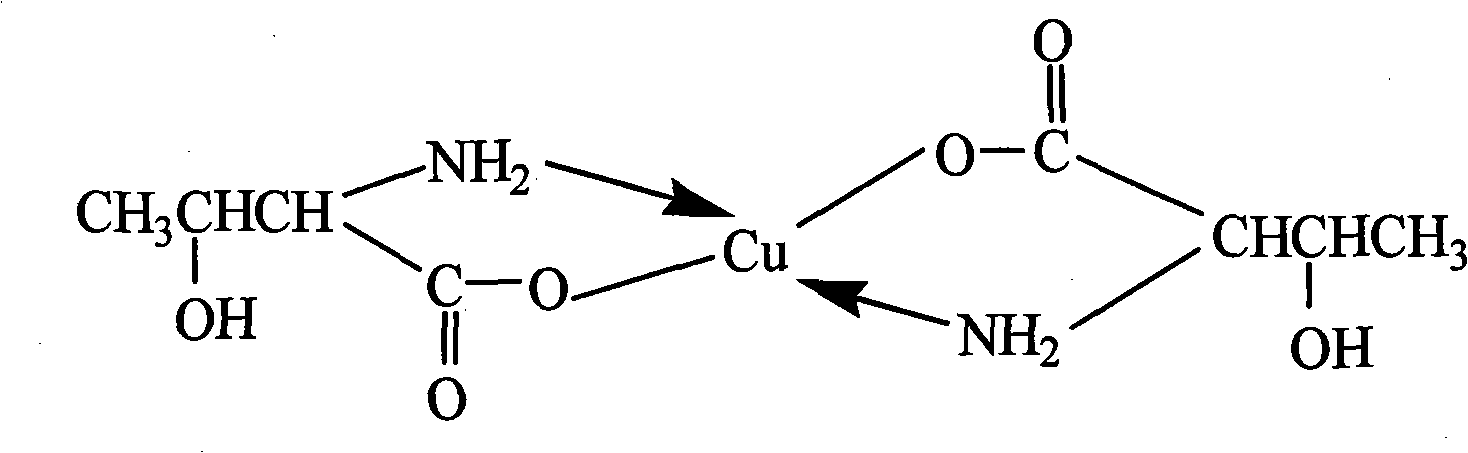

Method for preparing DL-threonine chelated copper serving as feed additive

A feed additive and chelated copper technology, which is applied in the field of preparation of feed additive DL-threonine chelated copper, can solve the problems of uncomfortable reaction route, low equipment investment and high production cost, and achieves high biological titer and equipment. The effect of low investment and short response route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] a. Preparation of glycine chelated copper

[0036]Take 100 grams of glycine, add 0.7 liters of water, heat and dissolve at 60°C, add 80 grams of basic copper carbonate, keep warm at 60°C for 1 hour, filter while hot to remove unreacted basic copper carbonate, and the filtrate crystallizes at 0°C, filter Dry at 60°C to obtain 119.2 g of glycine chelated copper.

[0037] b. Preparation of DL-threonine chelated copper

[0038] Take the glycine chelated copper obtained in step a, add 500 ml of methanol, stir to dissolve, cool to 5° C., add 200 ml of acetaldehyde, add 180 ml of 5% sodium hydroxide methanol solution, and keep the reaction at 60° C. for 1 hour. Filter while hot to remove insoluble matter, add 15 ml of glacial acetic acid to the filtrate, cool overnight, filter, and dry at 60°C to obtain 163.4 g of DL-threonine chelated copper, with a yield of 82%.

Embodiment 2

[0040] a. Preparation of glycine chelated copper

[0041] Take 110 grams of glycine, add 0.8 liters of water, heat and dissolve at 65°C, add 90 grams of basic copper carbonate, keep warm at 65°C for 1.5 hours, filter while hot to remove unreacted basic copper carbonate, the filtrate crystallizes at 1°C, filter , and dried at 60° C. to obtain 127.2 grams of glycine chelated copper.

[0042] b. Preparation of DL-threonine chelated copper

[0043] Glycine chelated copper obtained in step a, add 550 ml of methanol, stir to dissolve, cool to 6°C, add 240 ml of acetaldehyde, add 200 ml of 5% sodium hydroxide methanol solution, and heat at 70°C for 1 hour. Filter while hot to remove insoluble matter, add 20 ml of glacial acetic acid to the filtrate, cool overnight, filter, and dry at 60°C to obtain 177.5 g of DL-threonine chelated copper, with a yield of 81%.

Embodiment 3

[0045] a. Preparation of glycine chelated copper

[0046] Take 120 grams of glycine, add 0.85 liters of water, heat and dissolve at 70°C, add 100 grams of basic copper carbonate, keep warm at 70°C for 2 hours, filter while hot to remove unreacted basic copper carbonate, and the filtrate crystallizes at 2°C, filter Dry at 70°C to obtain 144.8 grams of glycine chelated copper.

[0047] b. Preparation of DL-threonine chelated copper

[0048] The glycine chelated copper obtained in step a was added with 700 ml of methanol, stirred and dissolved, cooled to 7° C., 260 ml of acetaldehyde was added, and 220 ml of 5% sodium hydroxide methanol solution was added, and the reaction was kept at 75° C. for 1 hour. Filter while hot to remove insoluble matter, add 25 ml of glacial acetic acid to the filtrate, cool overnight, filter, and dry at 65°C to obtain 191.3 grams of DL-threonine chelated copper, with a yield of 80%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com