Technique for producing soluble copper oxide from acidic etching waste liquor

A technology of acidic etching waste liquid and copper oxide, which is applied in the direction of copper oxide/copper hydroxide, photographic process, photographic auxiliary process, etc., can solve the problems of copper oxide activity verification, increase production cost, and a large amount of washing wastewater, so as to eliminate risks , little pollution and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

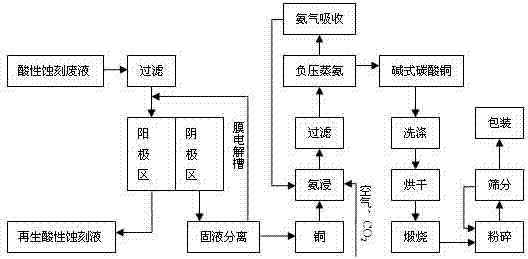

[0050] The process for producing soluble copper oxide from acidic etching waste liquid comprises the following steps: (1) collecting the acidic etching waste liquid online, and using the collected acidic etching waste liquid to remove the Fine insoluble particles, etc.;

[0051] (2) Pass the filtered acidic etching waste liquid into the membrane electrolyzer for ionic membrane electrolysis, and place a copper cation exchange membrane in the middle of the membrane electrolyzer;

[0052] The oxidation reaction of cuprous chloride complex ions in the anode area of the membrane electrolyzer generates copper chloride complex ions to realize the regeneration of acidic etching waste liquid:

[0053] 2(CuCl 3 ) 2- +Cl - →2(CuCl 4 ) 2- +2e

[0054] The reduction reaction of copper chloride ions in the cathode area produces copper;

[0055] 2(CuCl 4 ) 2- +Cu+2Cl - →2(CuCl 3 ) 2-

[0056] 2(CuCl 3 ) 2- →2(CuCl 2 ) - +2Cl -

[0057] 2(CuCl 2 ) 2- +2e→2Cu↓+4Cl

[00...

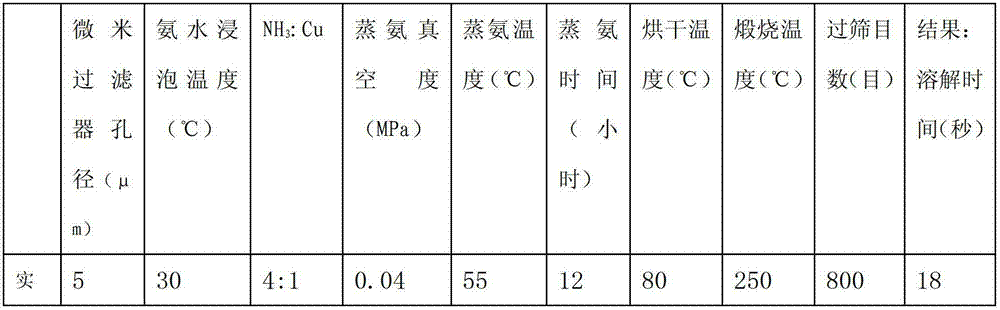

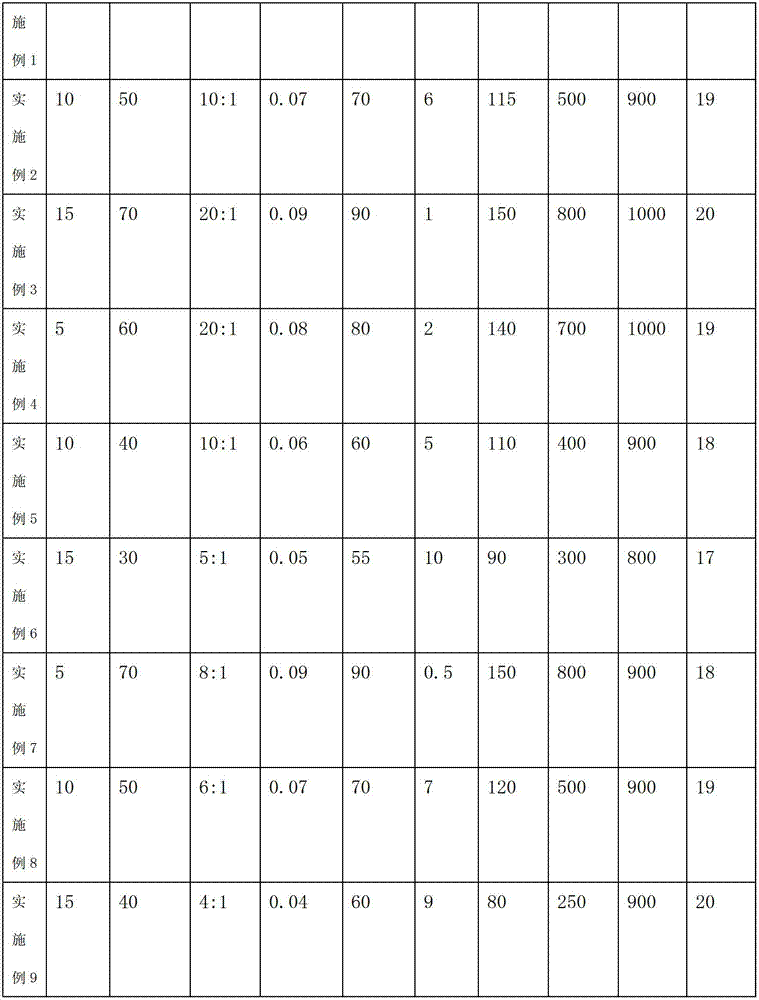

example 2- Embodiment 9

[0068] The same process as in Example 1 was used to prepare soluble copper oxide, and a test experiment was carried out. The difference is that different micron filter pore sizes listed in Table 1, NH 3 Ratio to the amount of Cu substance, soaking temperature of ammonia water, vacuum degree of ammonia distillation, temperature of ammonia distillation, time of ammonia distillation, drying temperature, calcining temperature, mesh number of sieve. The test results of the prepared copper oxide are also shown in Table 1.

[0069] Table 1

[0070]

[0071]

[0072] As can be seen from the test results shown in Table 1, the copper oxide produced by the process of the present invention has low impurity content and high activity, and can be completely dissolved in the electroplating solution within 20 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com