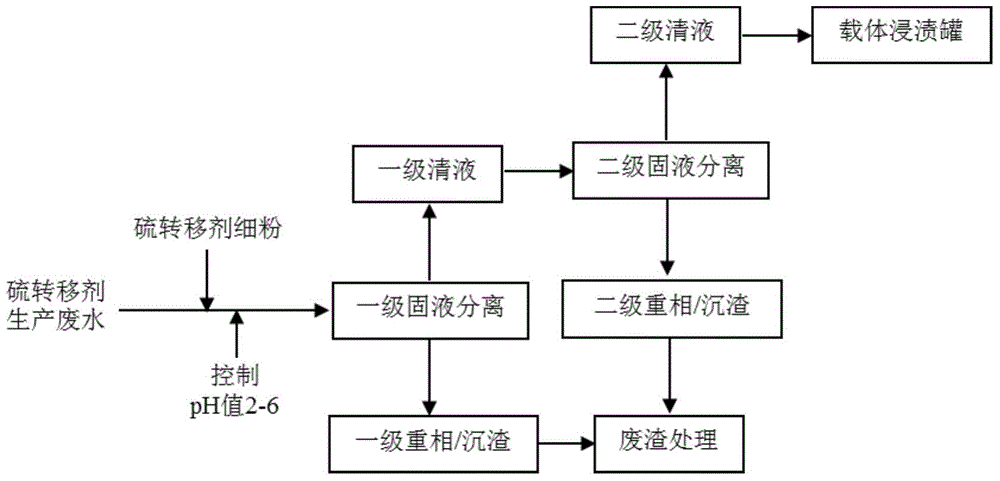

Sulfur transfer agent production wastewater recycling method

A technology of sulfur transfer agent and production wastewater, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc. Mesh blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of sulfur transfer agent is generally to first gelatinize magnesium hydroxide, magnesium oxide, aluminum oxide, clay, etc., as a carrier material, and then spray-dry to form carrier microsphere particles similar to the catalytic cracking catalyst. , The carrier microsphere particles are roasted, and then the active components mainly including cerium and other rare earth elements are loaded on the carrier by dipping in a dipping tank, and then dried. According to the present invention, the sulfur transfer agent production wastewater may be all wastewater generated during the production process of the sulfur transfer agent, for example, wastewater generated during immersion, wherein the pH value of the wastewater is about 5-8, and generally contains 物(RE 2 O 3 ), the rare earth elements in the waste water may exist in the form of ions or precipitates, and the waste water also contains 2-25 grams on a dry basis. Per liter of solid particles, the averag...

Embodiment 1

[0035] This embodiment illustrates the online recycling method of the sulfur transfer agent production wastewater of the present invention.

[0036] According to the volume flowmeter, add 10g of the sulfur transfer agent fine powder roasted at 650℃ for 1.5h to each liter of wastewater, stir and mix, and adjust the pH to 4 with hydrochloric acid. The wastewater suspension is pumped into the hydrocyclone, the inlet pressure is 0.35MPa, and the volume flow ratio of the underflow to the overflow is 1:8. The clear liquid from the overflow outlet is transported to the inlet of the tubular centrifuge. The centrifuge speed is 15000 rpm. The solid-phase sediment is removed every 1 hour. The average content of the clear liquid particles is 0.13g / L. The clear liquid is transported to the carrier impregnation tank for the sulfur transfer carrier to impregnate excessively loaded rare earths. 1m per cycle 3 The clear liquid can replace the same amount of fresh water while reducing the rare ea...

Embodiment 2

[0038] This example illustrates the online recycling method of the sulfur transfer agent production wastewater of the present invention.

[0039] According to a volume flow meter, add 5 g of fine sulfur transfer agent powder roasted at 650°C for 1.5 hours to each liter of wastewater, stir and mix, and adjust the pH to 5 with hydrochloric acid. The waste water suspension is pumped into the hydrocyclone, the inlet pressure is 0.4MPa, and the volume flow ratio of the underflow to the overflow is 1:10. The clear liquid from the overflow outlet is transported to the inlet of the tubular centrifuge. The centrifuge speed is 12000 rpm. The solid-phase sediment is removed every 1 hour. The average content of the clear liquid particles is 0.19g / L. The clear liquid is transported to the carrier impregnation tank for the sulfur transfer carrier to impregnate excessively loaded rare earths. 1m per cycle 3 The clear liquid can replace the same amount of fresh water while reducing the amount o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com