Method of preparing basic copper carbonate

A copper carbonate, basic technology, applied in chemical instruments and methods, copper compounds, inorganic chemistry and other directions, can solve the problems of high cost and difficult to meet market demand, reduce production costs, low raw material prices, improve production efficiency and The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

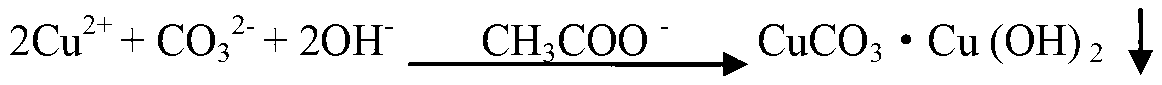

Method used

Image

Examples

Embodiment 1

[0024] (1) Inject an acidic solution containing copper chloride into the first container as the liquid A for use, and the Cu in the solution 2+ The mass concentration is 0.52%;

[0025] (2) Prepare a mixed solution containing sodium carbonate and sodium hydroxide in the second container, and the CO in the solution 3 2- with OH - molar ratio to CO 3 2- :OH-=1:0.5, as the standby solution B;

[0026] (3) Prepare the acetic acid solution in the third container as the liquid C for use;

[0027] (4) Add 500L of water to a 2000L jacketed and stirred reactor, and the water temperature is 90°C; pre-mix the liquid C and the liquid A in the intermediate container, so that Cu 2+ with CH 3 COO - The molar ratio of Cu 2+ :CH 3 COO - =1:0.05; the mixed solution and the liquid B to be used are simultaneously and slowly flowed into the fourth reactor, and a pH meter is used to monitor the pH value of the solution in the fourth reactor in real time during the reaction, so that the p...

Embodiment 2

[0031] (1) Inject an acidic solution containing copper sulfate into the first container as the standby solution A, the Cu in the solution 2+ The mass concentration is 6.3%;

[0032] (2) Prepare a mixed solution containing sodium bicarbonate and sodium hydroxide in the second container, and the CO in the solution 3 2- with OH - molar ratio to CO 3 2- : OH-=1:1, as the standby solution B;

[0033] (3) Potassium acetate solution is prepared in the third container as standby solution C;

[0034] (4) Add 500L of water to a 2000L jacketed and stirred reactor, the water temperature is 75°C; pre-mix the liquid C and the liquid B in the intermediate container, so that Cu 2+ with CH 3 COO - The molar ratio of Cu 2+ :CH 3 COO - =1:0.2; The mixed solution and the liquid A to be used are simultaneously and slowly flowed into the fourth reactor, and a pH meter is used to monitor the pH value of the solution in the fourth reactor in real time during the reaction, so that the pH in...

Embodiment 3

[0038] (1) Inject an acidic solution containing copper chloride into the first container as the liquid A for use, and the Cu in the solution 2+ The mass concentration is 10.5%;

[0039] (2) Prepare a mixed solution containing potassium carbonate, sodium hydroxide, and potassium hydroxide in the second container, and the CO in the solution 3 2- with OH - molar ratio to CO 3 2- : OH-=1:1.5, as the standby solution B;

[0040] (3) Sodium acetate solution was prepared in the third container as standby solution C;

[0041] (4) Add 500L of water to a 2000L jacketed and stirred reactor with a water temperature of 55°C; pre-mix the liquid C and the liquid B in the intermediate container so that Cu 2+ with CH 3 COO - The molar ratio of Cu 2+ :CH 3 COO - =1:0.4; the mixed solution and the liquid A to be used are simultaneously and slowly flowed into the fourth reactor, and a pH meter is used to monitor the pH value of the solution in the fourth reactor in real time during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com