Electronickelling method for neodymium iron boron sheet magnetic steel product

A neodymium iron boron and nickel electroplating technology, applied in the field of nickel electroplating, can solve the problems affecting the overall assembly of the product, poor coating distribution uniformity, excessive size and thickness difference, etc., and achieves high uniformity, low porosity, and uniform dispersion. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

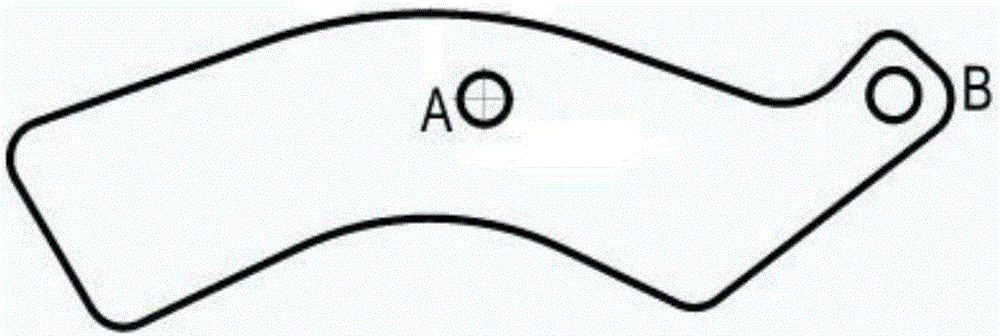

Image

Examples

Embodiment 1

[0026] Embodiment one: a kind of electroplating nickel method of NdFeB sheet magnetic steel product, comprises the following steps:

[0027] ① Pre-treatment of NdFeB thin sheet magnet products;

[0028] ② Pre-nickel-plating treatment of NdFeB thin-sheet magnetic steel products: the pre-nickel plating solution is composed of nickel sulfate, boric acid, sodium isethionate, hydroxypropyl sodium thiosulfate and water, and the mass volume concentration of nickel sulfate is 220 grams per liter, the mass volume concentration of boric acid is 30 grams per liter, the mass volume concentration of sodium isethionate is 10 mg / liter, and the mass volume concentration of hydroxypropyl sodium thiosulfate is 2 mg / liter. Nickel plating treatment time is 3500 seconds, double pulse power supply is used in the process of pre-nickel plating, the forward current density is 0.2 ampere / dm2, the reverse current density is 0.1 ampere / dm2, and the forward conduction time is 10 seconds, the reverse cond...

Embodiment 2

[0043] Embodiment two: a kind of electroplating nickel method of NdFeB sheet magnetic steel product, comprises the following steps:

[0044] ① Pretreatment of NdFeB thin sheet magnet products;

[0045] ② Pre-nickel-plating treatment of NdFeB thin-sheet magnetic steel products: the pre-nickel plating solution is composed of nickel sulfate, boric acid, sodium isethionate, hydroxypropyl sodium thiosulfate and water, and the mass volume concentration of nickel sulfate is 300 grams / liter, the mass volume concentration of boric acid is 50 grams / liter, the mass volume concentration of sodium isethionate is 25 mg / liter, and the mass volume concentration of hydroxypropyl sodium thiosulfate is 8 mg / liter. The nickel plating treatment time is 6500 seconds, and the double pulse power supply is used in the pre-nickel plating process. The forward current density is 0.8 ampere / square decimeter, the reverse current density is 0.3 ampere / square decimeter, and the forward conduction time is 20 ...

Embodiment 3

[0061] Embodiment three: a kind of electroplating nickel method of neodymium-iron-boron sheet magnetic steel product, comprises the following steps:

[0062] ① Pretreatment of NdFeB thin sheet magnet products;

[0063] ② Pre-nickel-plating treatment of NdFeB thin-sheet magnetic steel products: the pre-nickel plating solution is composed of nickel sulfate, boric acid, sodium isethionate, hydroxypropyl sodium thiosulfate and water, and the mass volume concentration of nickel sulfate is 250 grams per liter, the mass volume concentration of boric acid is 40 grams per liter, the mass volume concentration of sodium isethionate is 20 mg / liter, and the mass volume concentration of hydroxypropyl sodium thiosulfate is 5 mg / liter. Nickel plating treatment time is 5000 seconds, double pulse power supply is used in the process of pre-nickel plating treatment, its forward current density is 0.6 ampere / square decimeter, reverse current density is 0.2 ampere / square decimeter, forward conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com