Environment-friendly de-plating liquid of copper plating layer and de-plating process of reproducible de-plating liquid

A stripping solution and environment-friendly technology, applied in the field of stripping solution and stripping process, can solve the problems of equipment and workshop corrosion, serious environmental pollution, over-corrosion of the substrate, etc., and achieve stable stripping solution, high efficiency and stable reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Coating thickness: 25μm-30μm;

[0051] Coating size: 4cm×5cm;

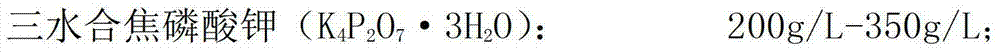

[0052] Prepare 350mL deplating solution, the components of the deplating solution are as follows:

[0053]

[0054] Deplating conditions: temperature 35°C-40°C; mechanical stirring; each stripping 0.2dm 2 Add 20mL of hydrogen peroxide (30%) to the coating.

[0055] Deplating time: 4min-15min.

[0056] Deplating solution regeneration: complete 2dm 2 After deplating of the area coating, the regeneration of the deplating solution is carried out, and the regeneration conditions are:

[0057] 1. Add excess manganese dioxide, filter, and concentrate the filtrate by electrodialysis to the same volume as the original deplating solution.

[0058] 2. The ruthenium-titanium oxide-coated DSA anode with a 2mm-thick mesh structure has an effective size of 6cm×6cm, and the stainless steel substrate is the cathode with an effective size of 6cm×6cm. The current density is 2A / dm 2 Under electrolysis for 34 minutes, ...

Embodiment 2

[0061] Coating thickness: 25μm-30μm;

[0062] Coating size: 4cm×5cm;

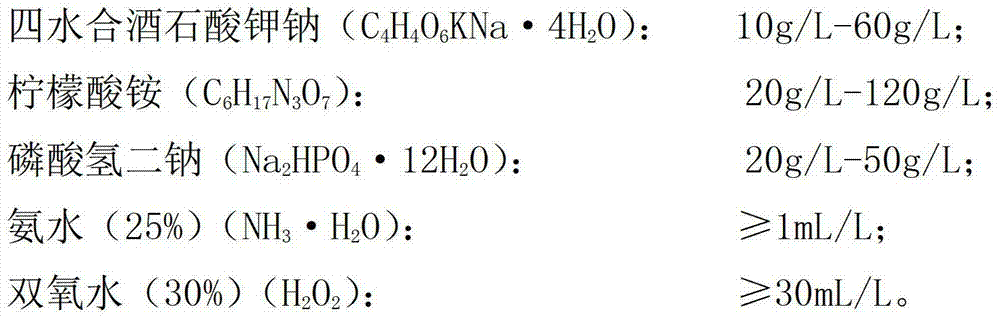

[0063] Prepare 350mL deplating solution, the components of the deplating solution are as follows:

[0064]

[0065] Deplating conditions: temperature 35°C-40°C; mechanical stirring; each stripping 0.2dm 2 Add 24mL of hydrogen peroxide (30%) to the coating.

[0066] Deplating time: 3min-14min.

[0067] Deplating solution regeneration: with embodiment one

Embodiment 3

[0069] Coating thickness: 25μm-30μm;

[0070] Coating size: 4cm×5cm;

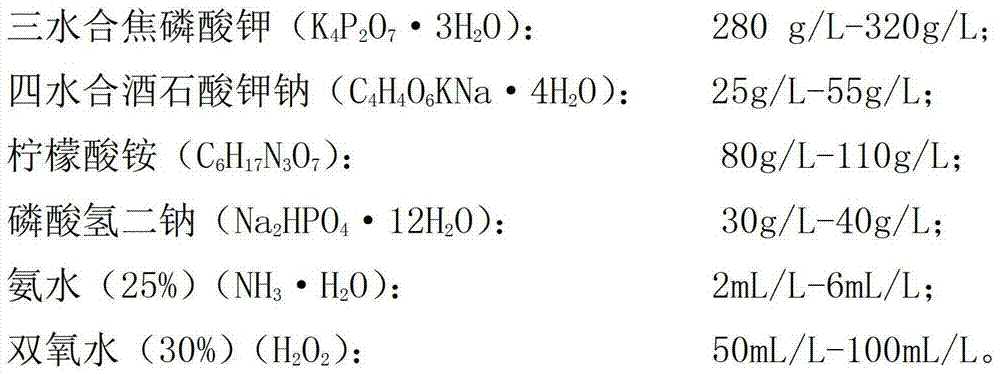

[0071] Prepare 350mL deplating solution, the components of the deplating solution are as follows:

[0072]

[0073]

[0074] Deplating conditions: temperature 35°C-40°C; mechanical stirring; each stripping 0.2dm 2 Add 12mL of hydrogen peroxide (30%) to the coating.

[0075] Deplating time: 3min-18min.

[0076] Deplating solution regeneration: with embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com