Method of electroless copper plating on surface of boron carbide powder and electroless plating solution for electroless copper plating

A technology of surface chemistry and chemical plating solution, applied in the field of chemical plating, can solve problems such as toxic heavy metal ions, environmental pollution, etc., and achieve the effects of less environmental pollution, low price, and strong reducing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

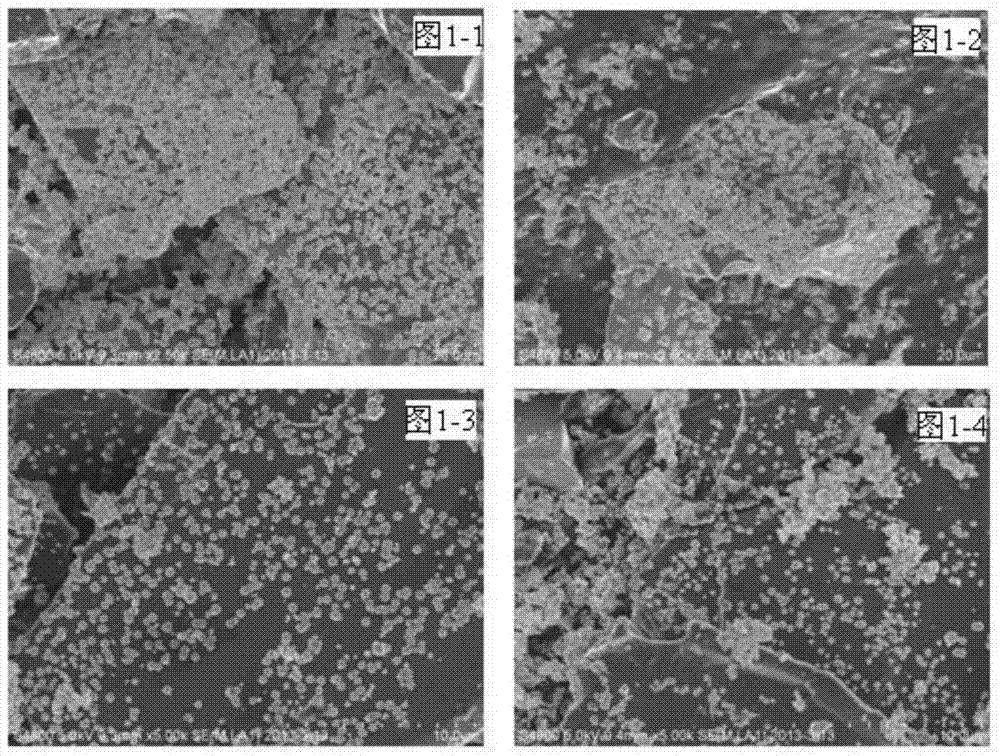

[0029] Pre-plating treatment

[0030] Degreasing: Put 50g of boron carbide powder in acetone liquid, ultrasonic and stir for 30min, then take it out, dry at 80℃, and reach constant weight for later use.

[0031] Alkaline washing: place the boron carbide powder after degreasing in a 1mol / L sodium hydroxide hot alkaline solution at 80°C for ultrasonic cleaning and stirring for 30min, then take it out and dry it at 80°C until it is ready for use.

[0032] Sensitization: Place the boron carbide powder after alkali washing in a mixed solution of 20g / L stannous chloride and 60ml / L hydrochloric acid and stir for 30min for sensitization, then take it out and dry at 80°C until it is ready for use.

[0033] Activation: Place the sensitized boron carbide powder in a mixed solution of 0.05g / L palladium chloride and 8ml / L hydrochloric acid and stir for 10 minutes for sensitization, then take it out and dry it at 80°C to a constant weight for later use.

[0034] Electroless plating treatment

[0035] ...

Embodiment 2

[0039] Example 2 is the same as the pre-plating treatment and post-plating treatment in Example 1, except that the electroless plating solution contains 15g / L copper sulfate, 20g / L disodium ethylenediaminetetraacetic acid, and 10g / L potassium sodium tartrate. And 20ml / L hydrazine hydrate, the pH value of the electroless plating solution is 12-13, and in the electroless plating treatment of Example 2, the pH value is 12 and the holding temperature is 70°C; degreasing treatment, alkaline washing treatment, sensitive In both chemical treatment and activation treatment, the drying temperature is 150°C.

Embodiment 3

[0041] Example 2 is the same as the pre-plating and post-plating treatments in Example 1, except that the electroless plating solution contains 20g / L copper sulfate, 30g / L disodium ethylenediaminetetraacetic acid, and 14g / L potassium sodium tartrate. And 18ml / L hydrazine hydrate, the pH value of the electroless plating solution is 12-13, and the pH value used in the electroless plating treatment in Example 2 is 13, and the holding temperature is 80°C; degreasing treatment, alkaline washing treatment, sensitization In the treatment and activation treatment, the drying temperature is 120°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com