Preparation method of manganese tungsten single-crystalline nanowire

A manganese tungstate single crystal and nanowire technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of complicated operation, expensive template, complicated operation of template method, etc., and achieve the effect of good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

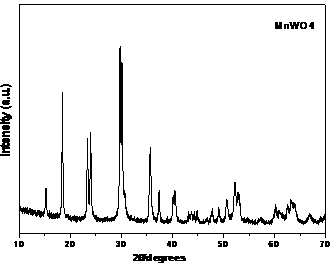

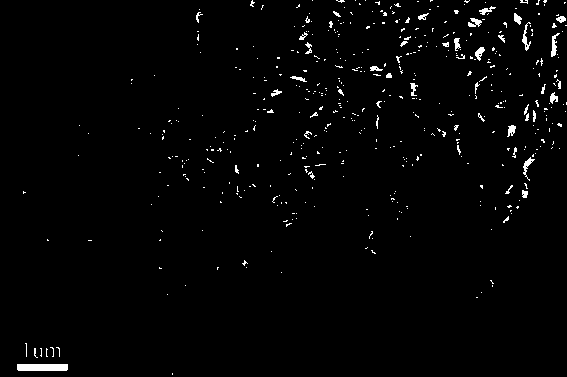

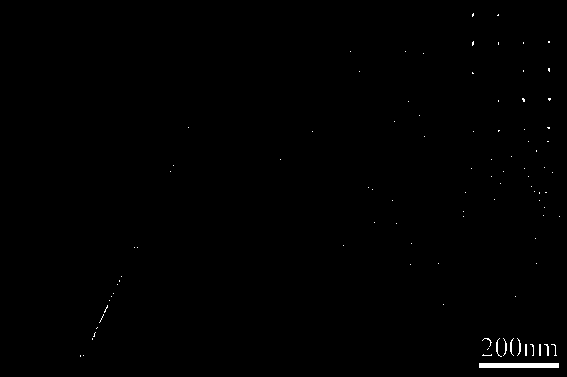

Image

Examples

preparation example Construction

[0016] As shown in the figure, a method for preparing manganese tungstate single crystal nanowires comprises the following steps:

[0017] Step 1, prepare the deionized aqueous solution of manganese chloride, potassium sodium tartrate and potassium carbonate respectively;

[0018] Step 2, take the manganese chloride deionized aqueous solution prepared in step 1 and the potassium sodium tartrate deionized aqueous solution and mix according to equimolar amounts to obtain a manganese tartrate precipitation solution as a reaction precursor for subsequent use;

[0019] Step 3, adding the potassium carbonate deionized aqueous solution prepared by equimolar step 1 in the manganese tartrate precipitation solution obtained in step 2, after mixing uniformly, add it into a hydrothermal reaction kettle to carry out hydrothermal reaction, generate manganese carbonate precipitation solution, and set aside;

[0020] Step 4. Cool the hydrothermal reaction kettle in step 3 to room temperature,...

Embodiment 1

[0026] Step 1, dissolving manganese chloride in deionized water to form an aqueous manganese chloride solution, adjusting the concentration of manganese chloride in the solution to be 0.1mol / L;

[0027] Step 2, sodium potassium tartrate is dissolved in deionized water to form an aqueous solution of sodium potassium tartrate, and the concentration of sodium sodium tartrate in the adjustment solution is 0.1mol / L;

[0028] Step 3, dissolving potassium carbonate in deionized water to form an aqueous solution of potassium carbonate, adjusting the concentration of potassium carbonate in the solution to be 0.1mol / L;

[0029] Step 4, mixing the manganese chloride solution prepared in step 1 with the potassium sodium tartrate solution prepared in step 2 according to equimolarity to obtain manganese tartrate precipitate as a reaction precursor;

[0030] Step 5. Mix the potassium carbonate solution prepared in step 3 with the manganese tartrate precipitation solution prepared in step 4 a...

Embodiment 2

[0035] Step 1, dissolve manganese chloride in deionized water to form an aqueous manganese chloride solution, and adjust the concentration of manganese chloride in the solution to be 2.1mol / L;

[0036] Step 2, potassium sodium tartrate is dissolved in deionized water to form potassium sodium tartrate aqueous solution, and the concentration of potassium sodium tartrate in the adjustment solution is 2.1mol / L;

[0037] Step 3, potassium carbonate is dissolved in deionized water to form an aqueous solution of potassium carbonate, and the concentration of potassium carbonate in the adjustment solution is 2.1mol / L;

[0038] Step 4, mixing the manganese chloride solution prepared in step 1 with the potassium sodium tartrate solution prepared in step 2 according to equimolarity to obtain manganese tartrate precipitate as a reaction precursor;

[0039] Step 5. Mix the potassium carbonate solution prepared in step 3 with the manganese tartrate precipitation solution prepared in step 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com