Eu doped YPO4 microballoon and preparation method thereof

A microsphere, eu2o3 technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of poor crystallinity, poor crystal grain dispersion, and complex process in chemical precipitation method, and achieve controllable structure, easy control, and process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Take 0.5 ml of 1 mol L -1 YCl 3 solution, and then add EuCl 3 The solution is fully mixed (Eu10%, mass ratio);

[0025] (2) Under stirring conditions, add 1 mmol potassium sodium tartrate and 1 mmol trisodium phosphate in turn, and stir for 10 min to dissolve completely to ensure that the reactants are evenly mixed;

[0026] (3) Use 1mol under stirring condition . L -1 Adjust the pH value of the mixed solution to pH=2 with dilute hydrochloric acid;

[0027] (4) Transfer the above mixed solution to a stainless steel reaction kettle with polytetrafluoroethylene lining, seal it, react at 180 °C for 24 h, and cool it to room temperature naturally;

[0028] (5) The obtained precipitate was centrifuged (4000 r / min) for 5 min, and the precipitate was repeatedly washed with water and ethanol, and then centrifuged. Put it in a drying oven at 60°C and dry it to get YPO 4 : Eu microspheres.

[0029]

Embodiment 2

[0031] (1) Take 0.5 ml of 1 mol L -1 YCl 3 solution, and then add EuCl 3 The solution is fully mixed (Eu 6%, mass ratio);

[0032] (2) Under stirring conditions, add 2 mmol potassium sodium tartrate and 2 mmol trisodium phosphate in turn, and stir for 10 min to dissolve completely to ensure that the reactants are mixed evenly;

[0033] (3) Use 1 mol under stirring condition . L -1 Adjust the pH of the mixed solution to 3 with dilute hydrochloric acid;

[0034] (4) Transfer the above mixed solution to a stainless steel reaction kettle with polytetrafluoroethylene lining, seal it, react at 200 °C for 24 h, and naturally cool to room temperature;

[0035] (5) The obtained precipitate was centrifuged (4000 r / min) for 5 min, and the precipitate was repeatedly washed with water and ethanol, and then centrifuged. Put it in a drying oven at 60°C and dry it to get YPO 4 : Eu microspheres.

[0036]

Embodiment 3

[0038] (1) Take 2 ml of 1 mol L -1 YCl 3 solution, and then add EuCl 3 The solution is fully mixed (Eu 3%, mass ratio);

[0039] (2) Under stirring conditions, add 2 mmol potassium sodium tartrate and 2 mmol trisodium phosphate in turn, and stir for 10 min to dissolve completely to ensure that the reactants are mixed evenly;

[0040] (3) Use 1 mol under stirring condition . L -1 The pH of the mixed solution adjusted by dilute hydrochloric acid=2;

[0041](4) Transfer the above mixed solution to a stainless steel reaction kettle with polytetrafluoroethylene lining, seal it, react at 160 °C for 12 h, and naturally cool to room temperature;

[0042] (5) The obtained precipitate was centrifuged (4000 r / min) for 5 min, and the precipitate was repeatedly washed with water and ethanol, and then centrifuged. Put it in a drying oven at 60°C and dry it to get YPO 4 : Eu microspheres.

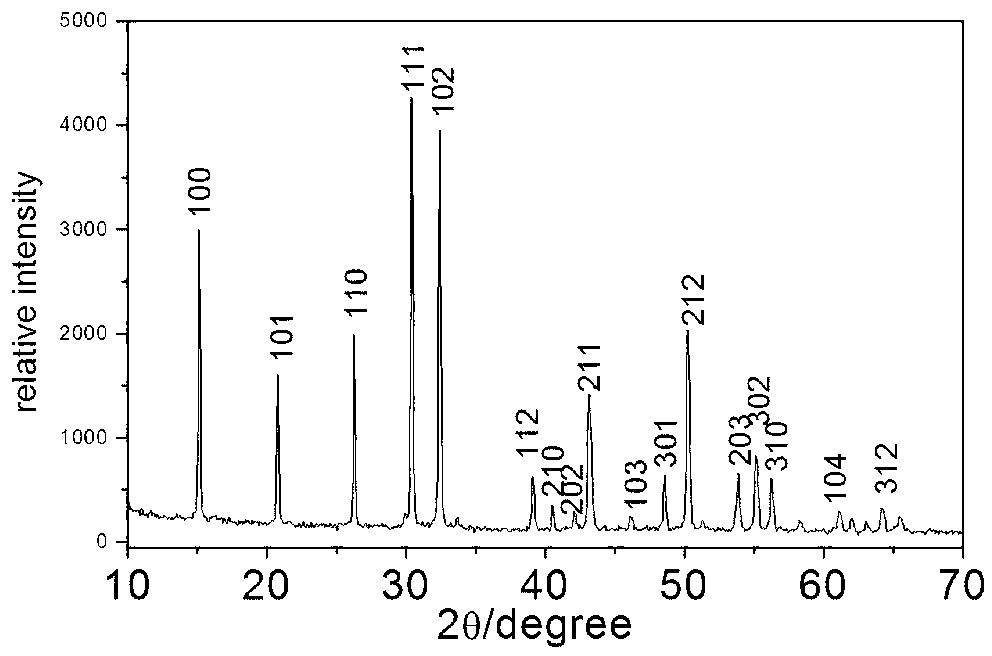

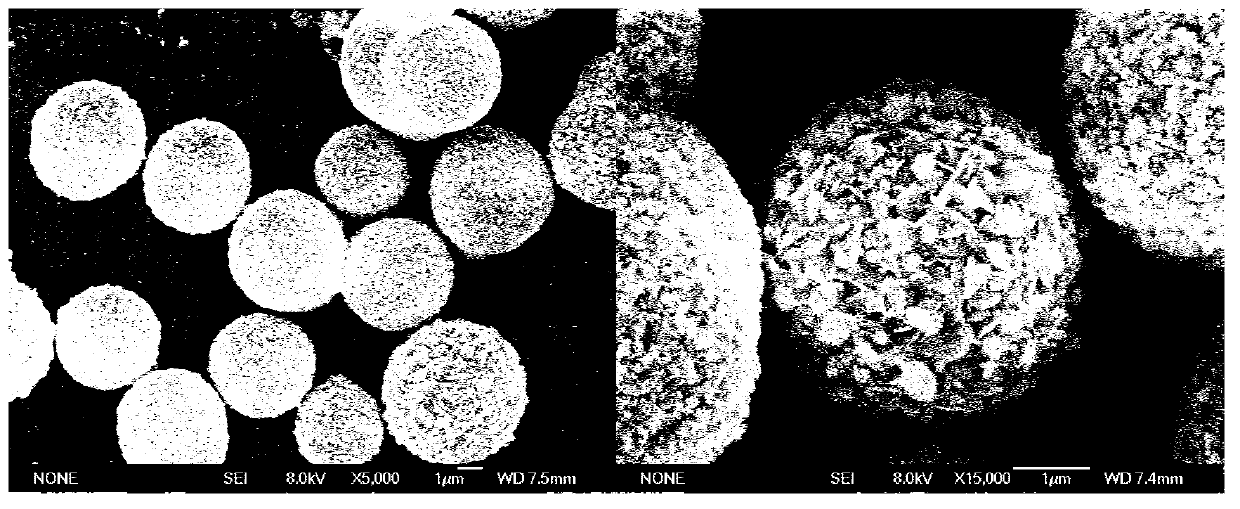

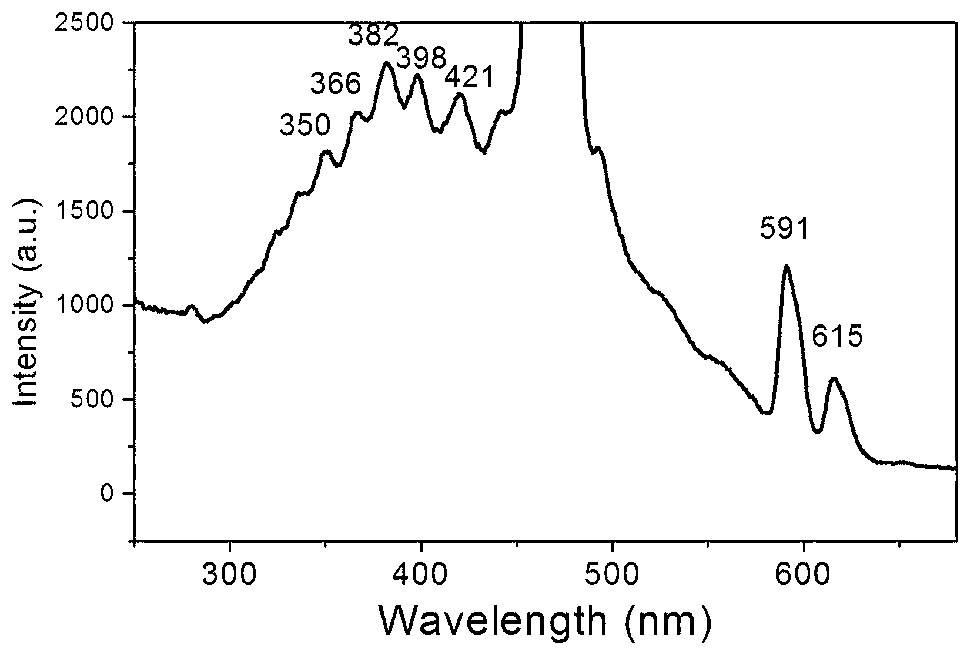

[0043] figure 1 For utilizing the YPO prepared by the method described in the embodiment of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com