Electroplating method for magnesium and magnesium alloy

a technology of electroplating method and magnesium alloy, which is applied in the direction of liquid/solution decomposition chemical coating, coating, metallic material coating process, etc., can solve the problems of affecting the quality of electroplating and difficulty in electroplating magnesium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

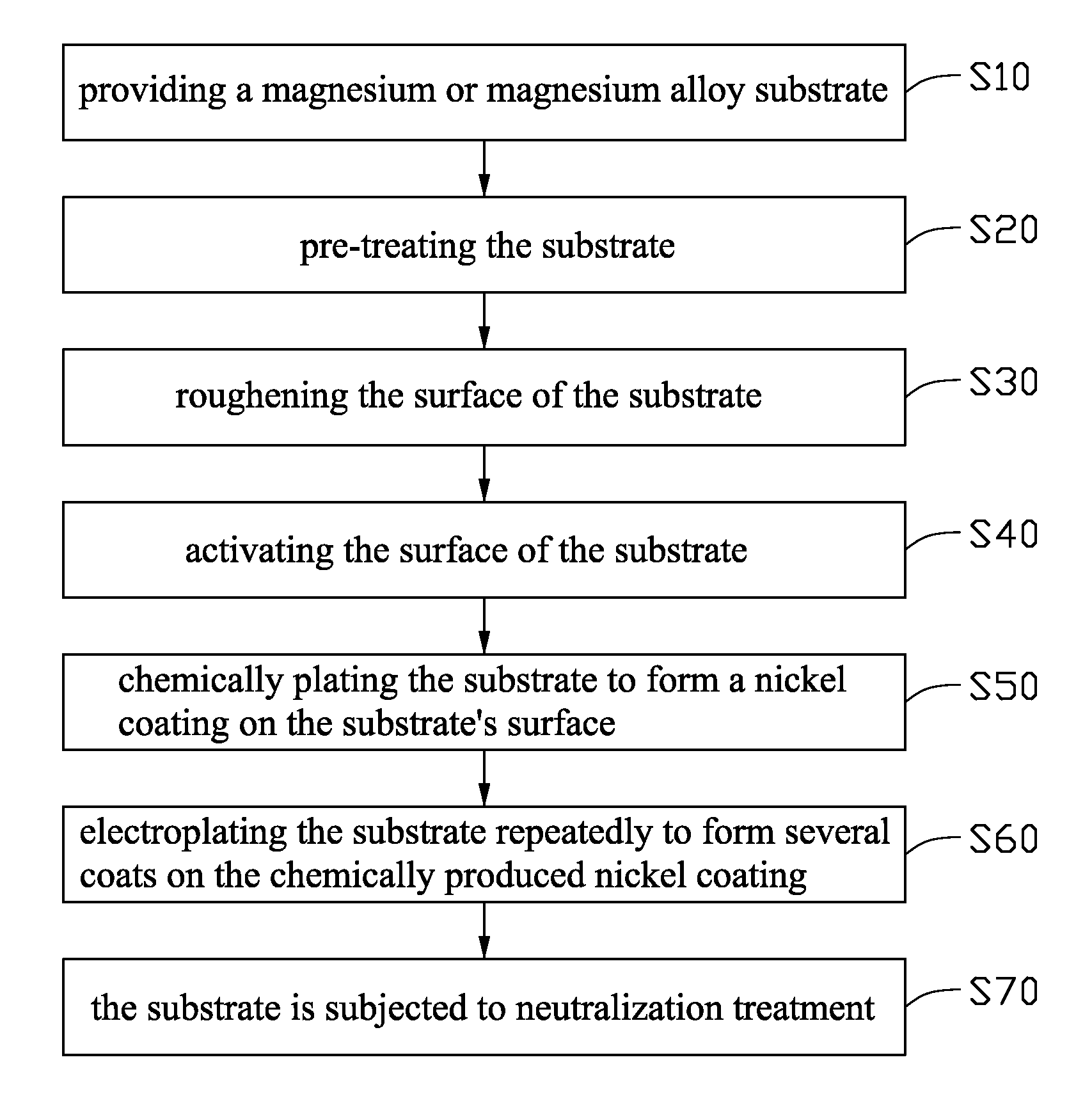

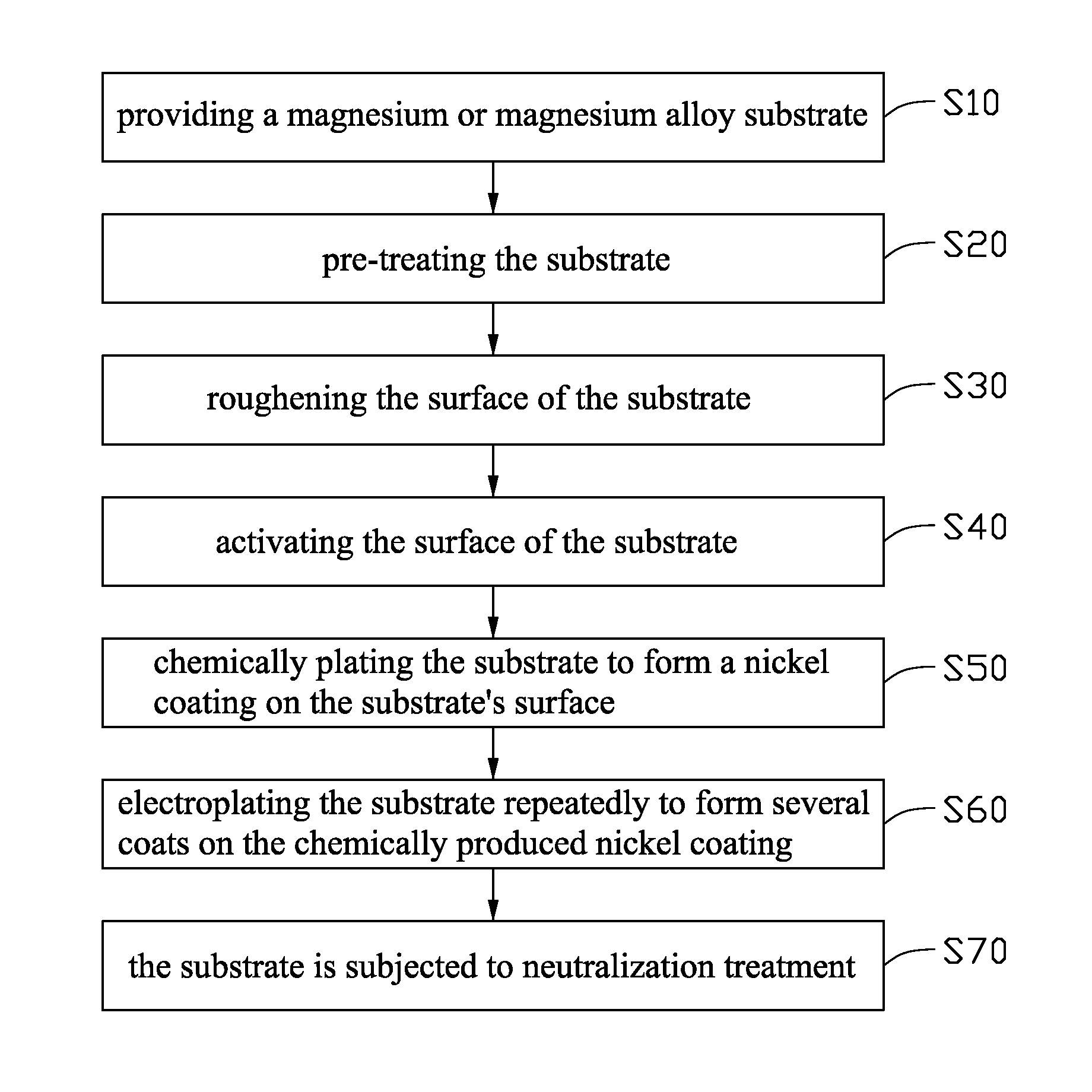

[0008]Referring to the FIGURE, an electroplating method for magnesium and magnesium alloys may include the steps S10 to S70.

[0009]In step S10, a magnesium or a magnesium alloy substrate is provided. The substrate may be a housing of a mobile phone, a digital camera, a personal digital assistant, or a note-book computer. The substrate may also be a housing of a container.

[0010]In step S20, the substrate is pretreated. The pre-treating step may comprise degreasing and cleaning the substrate. The degreasing process may be carried out by dipping the substrate in a degreasing solution for about 5-15 minutes. The mass concentration of the degreasing solution is about 150-200 grams per liter (g / L). The temperature of the degreasing solution is about 75-90° C. After the degreasing process, the substrate is removed from the degreasing solution and bathed in water. Then, the substrate is dipped in a sodium hydroxide solution for about 4-10 minutes to be polished. The sodium hydroxide solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass concentration | aaaaa | aaaaa |

| mass concentration | aaaaa | aaaaa |

| mass concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com