Aluminum alloy cylinder sleeve for automobile engine and preparation method of aluminum alloy cylinder sleeve

An automobile engine and aluminum alloy technology, which is applied to engine components, machines/engines, cylinders, etc., can solve the problems of inability to meet engine requirements, low performance and service life of aluminum alloy cylinder liners, and achieve an increase in the number of crystal nuclei, The effect of grain refinement and increased thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a method for preparing an aluminum alloy cylinder liner for an automobile engine described in any one of the above, comprising the following steps:

[0046] 1) Smelting: smelting Al source, Si source, C source, Mg source, Cr source, Cu source, Mn source, RE source, Zn source, Ti source into a melt;

[0047] 2) Die-casting: Die-casting the melt obtained in step 1) to obtain an aluminum alloy cylinder liner blank;

[0048] 3) Machining: the aluminum alloy cylinder liner blank obtained in the step 2) is sequentially subjected to rough turning, rough boring, turning process outer circle, fine boring and fine turning outer circle to obtain a tubular aluminum alloy substrate;

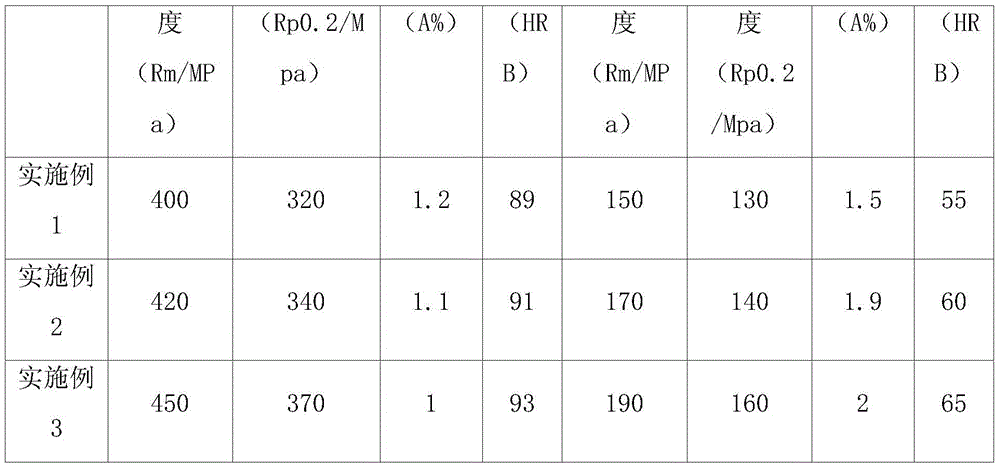

[0049] 4) Chromium electroplating: the inner surface of the aluminum alloy substrate obtained in the step 3) is sequentially cleaned with an organic solvent, degreased, soaked in heavy metal salts, pickled, zinc dipped once, zinc stripped, brightened, zinc dipped twi...

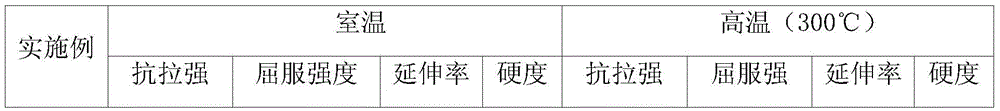

Embodiment 1

[0092] 1) Add a certain quality of pure aluminum ingots into the crucible, heat to 760°C, melt the pure aluminum ingots into a melt, and then add Al-Cr master alloy and Al-Cu master alloy to the melt in turn according to the ratio , Al-Mn master alloy, Al-RE master alloy, Al-Si master alloy, Al-Zn master alloy, Al-Ti master alloy, heat up to 840 ° C, keep warm for 6 hours, stir after the solid alloy is completely melted, turn on the electromagnetic Mixer, stir for 1 hour, and add 0.5% of the composite phosphorus modifier of the melt quality, then cool down to 760°C, add Al-C master alloy and Al-Mg master alloy according to the proportion, turn on the electromagnetic stirrer again, and stir For 1 hour, degas with nitrogen for 20 minutes, take a sample to test the composition of the melt, and control the melt to include the following components in weight percentage: Si: 13%; Cu: 2%; Mg: 0.2%; Cr: 0.1%; C : 0.3%; Mn: 0.1%; Zn: 0.5%; Ti: 0.02%; RE: 0.3%; A certain amount of melt ...

Embodiment 2

[0100]1) Add a certain quality of pure aluminum ingots into the crucible, heat to 770°C, melt the pure aluminum ingots into a melt, and then add Al-Cr master alloy and Al-Cu master alloy to the melt in turn according to the ratio , Al-Mn master alloy, Al-RE master alloy, Al-Si master alloy, Al-Zn master alloy, Al-Ti master alloy, heat up to 840 ° C, keep warm for 6 hours, stir after the solid alloy is completely melted, turn on the electromagnetic Mixer, stir for 1 hour, and add 0.5% of the composite phosphorus modifier of the melt quality, then cool down to 760°C, add Al-C master alloy and Al-Mg master alloy according to the proportion, turn on the electromagnetic stirrer again, and stir For 1 hour, degas with nitrogen for 20 minutes, take a sample to test the composition of the melt, and control the melt to include the following components in weight percentage: Si: 14%; Cu: 1.6%; Mg: 0.36%; Cr: 0.21%; C : 0.23%; Mn: 0.21%; Zn: 0.28%; Ti: 0.08%; RE: 0.19%; A certain amount o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corner radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com