Alloy antiseptic composite coating for coal mine underground gas pipe

A composite coating and anti-corrosion coating technology, applied in anti-corrosion coatings, pipeline anti-corrosion/rust protection, coatings, etc., can solve the problem that the corrosion resistance cannot meet the anti-corrosion requirements of gas drainage pipes, and the impact resistance of polymer plastics is not good. High cost, easy to fall off and other problems, to achieve the effect of high cost performance, excellent flame retardant performance, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 100g of aluminum flakes, 5g of zinc flakes, 10g of polyoxyethylene octylphenol ether, and 1g of carboxymethyl cellulose were uniformly mixed to obtain paste A; 5g of chromic anhydride was dissolved in 80g of deionized water to obtain solution B. After mixing components A and B at a mass ratio of 1:1.5, stir and disperse evenly, spray on the surface of the base pipe, and sinter at 300°C for 45 minutes to form an aluminum-zinc-chromium coating I on the surface of the base pipe.

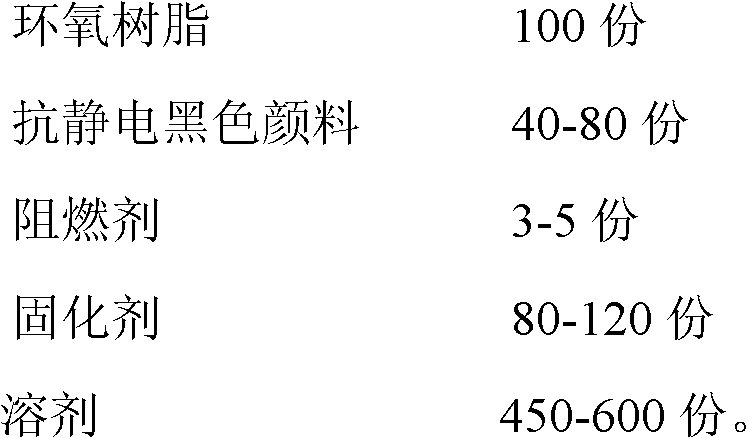

[0036] 100g brominated epoxy resin, 40g conductive carbon black, 3g triphenyl phosphate, 80g low molecular polyamide resin, 150g toluene, 150g isopropanol, 150g kerosene were stirred and dispersed evenly, sprayed on the surface of aluminum zinc chromium coating I, the surface After drying, it is sintered at 170°C for 45 minutes to form a flame-retardant, anti-static and anti-corrosion coating II on the surface of the aluminum-zinc-chromium coating I to obtain an alloy anti-corrosion composite coat...

Embodiment 2

[0038] 100g of aluminum flakes, 10g of zinc flakes, 20g of polyethylene glycol alkylphenol polyoxyethylene ether, and 2g of carboxymethyl cellulose were uniformly mixed to obtain paste A; 5g of chromic anhydride was dissolved in 70g of deionized water to obtain solution B. After mixing components A and B at a mass ratio of 1:1.5, stir and disperse evenly, spray on the surface of the base pipe, and sinter at 350°C for 30 minutes to form an aluminum-zinc-chromium coating I on the surface of the base pipe.

[0039] 100g brominated epoxy resin, 40g graphite, 3g antimony trioxide, 100g low-molecular polyamide resin, 100g benzene, 150g isopropanol, 200g kerosene, stir and disperse evenly, spray on the surface of aluminum-zinc-chromium coating I, after the surface is dry Sintering at 180°C for 30 minutes forms a flame-retardant, antistatic, anti-corrosion coating II on the surface of the Al-Zn-Cr coating I, and obtains an alloy anti-corrosion composite coating for underground gas pipe...

Embodiment 3

[0041] 100g of aluminum flakes, 20g of zinc flakes, 30g of lauryl polyoxyethylene ether, and 1g of sodium polyacrylate were uniformly mixed to obtain paste A; 10g of chromic anhydride was dissolved in 80g of deionized water to obtain solution B. After mixing components A and B at a mass ratio of 1:1.5, stir and disperse evenly, spray on the surface of the base pipe, and sinter at 330°C for 35 minutes to form an aluminum-zinc-chromium coating I on the surface of the base pipe.

[0042] 100g brominated epoxy resin, 30g Fe 3 o 4 , 5g antimony trioxide, 60g low-molecular polyamide resin, 20g tung oil anhydride, 100g benzene, 150g isopropanol, 200g acetone, stir and disperse evenly, spray on the surface of aluminum-zinc-chromium coating I, sinter at 170°C for 40min after surface drying, A flame-retardant, antistatic and anti-corrosion coating II is formed on the surface of the aluminum-zinc-chromium coating I to obtain an alloy anti-corrosion composite coating for underground gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com