Door rod strengthening technology for air pump recycling regulation door

A recirculation and door adjustment technology, which is applied in metal material coating process, molten spraying, coating, etc., can solve problems such as uneven quenching thickness and blown sealing surface, so as to improve wear resistance and increase service life , The effect of simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

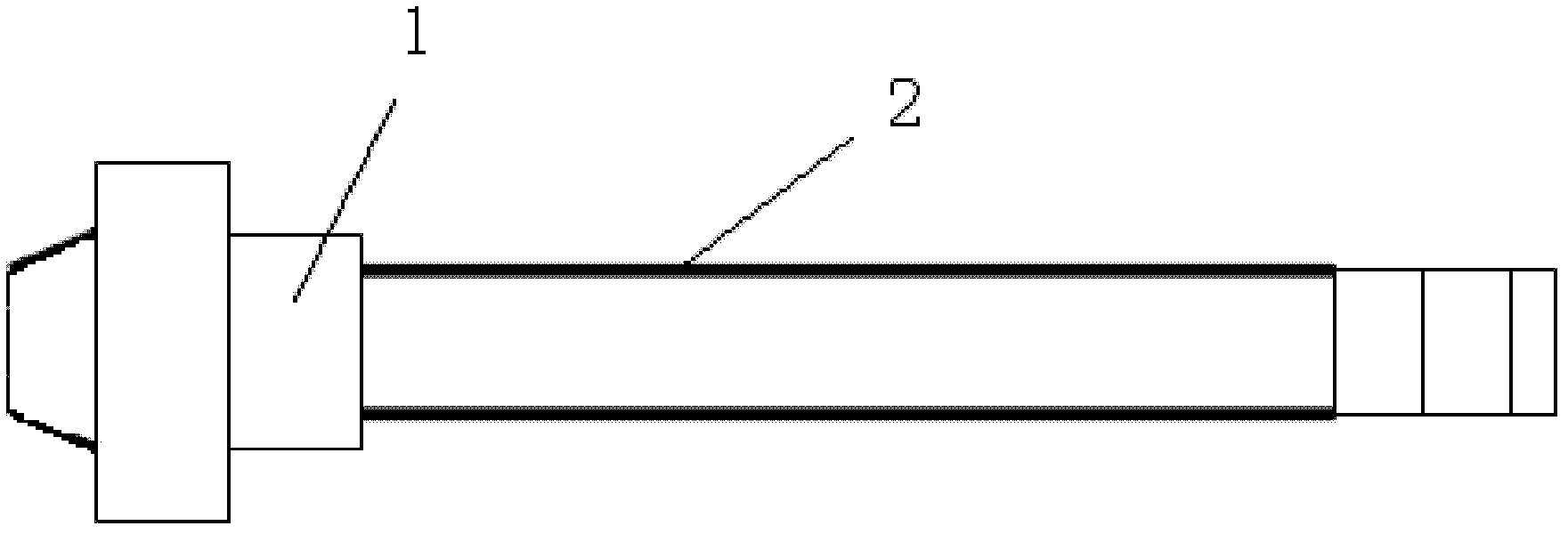

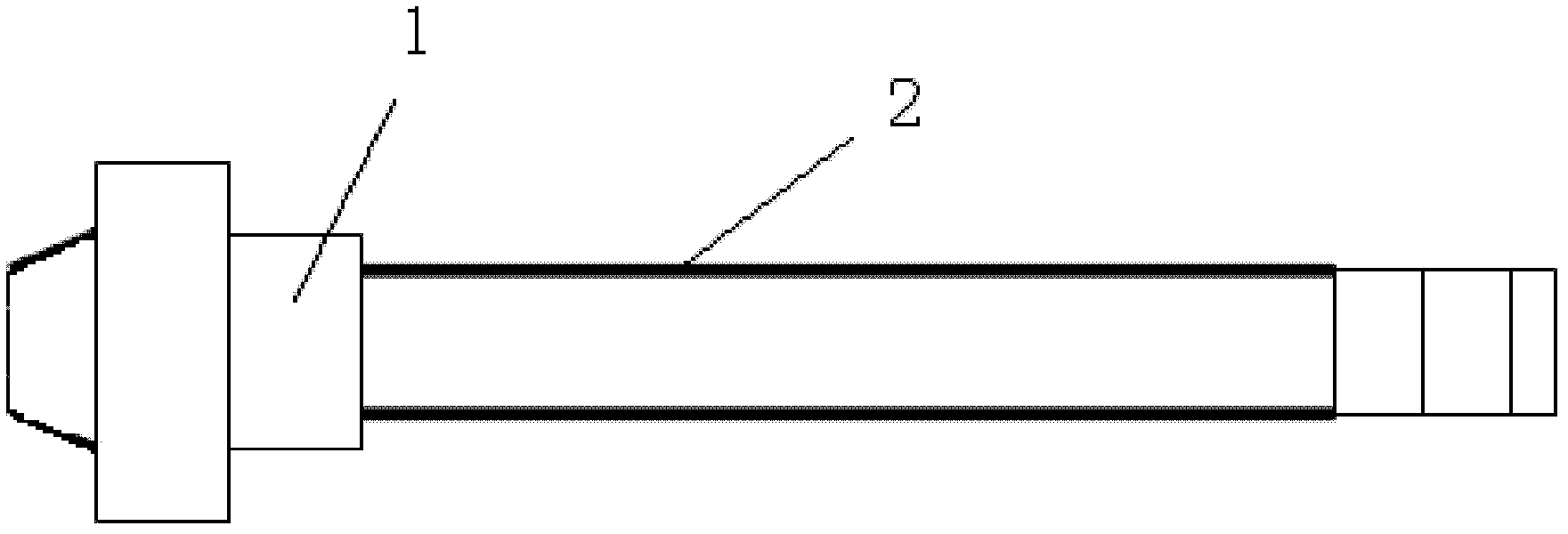

[0025] see figure 1 , the supersonic spraying strengthening process of the door lever of the steam pump recirculation adjustment door, the steps are as follows:

[0026] 1. Primary processing:

[0027] Grind the stem part of the door lever 1 to a thickness of 0.18mm;

[0028] Second, the workpiece surface purification:

[0029] Use an oxygen-acetylene flame gun to bake the surface of the door lever 1 with a flame, and the surface temperature of the workpiece is 100°C:

[0030] 3. Surface pretreatment:

[0031] 12 # Brown corundum sand is used to sandblast the surface of the door lever 1, and the compressed air pressure is 0.5kg / cm 2 , the surface roughness after blasting reaches Sa3 level;

[0032] 4. Spraying metal ceramic coating

[0033] Use supersonic flame spray gun to face the door, the surface of the rod part of 1 is sprayed with metal ceramic coating 2, the material is NiCr-Cr 2 C 3 Spraying powder; the flame center line of the spray gun intersects the axis of...

Embodiment 2

[0039] see figure 1 , the supersonic spraying strengthening process of the door lever of the steam pump recirculation adjustment door, the steps are as follows:

[0040] 1. Primary processing:

[0041] Grind the stem part of the door lever 1 to a thickness of 0.19mm;

[0042] Second, the workpiece surface purification:

[0043] Use an oxygen-acetylene flame gun to flame-bake the surface of the door lever 1, and the surface temperature of the workpiece is 120°C;

[0044] 3. Surface pretreatment:

[0045] 12 # Brown corundum sand is used to sandblast the surface of the door lever 1, and the compressed air pressure is 0.6kg / cm 2 , the surface roughness after blasting reaches Sa3 level;

[0046] 4. Spraying metal ceramic coating

[0047] Use a supersonic flame spray gun to spray a cermet coating 2 on the surface of the door lever 1, and the material is NiCr-Cr 2 C 3 Spraying powder; the flame center line of the spray gun intersects the axis of the workpiece perpendicularl...

Embodiment 3

[0053] see figure 1 , the supersonic spraying strengthening process of the door lever of the steam pump recirculation adjustment door, the steps are as follows:

[0054] 1. Primary processing:

[0055] Grind the stem part of the door lever 1 to a thickness of 0.20mm;

[0056] Second, the workpiece surface purification:

[0057] Use an oxygen-acetylene flame gun to flame-bake the surface of the door lever 1, and the surface temperature of the workpiece is 150°C;

[0058] 3. Surface pretreatment:

[0059] 12 # Brown corundum sand is used to sandblast the surface of the door lever 1, and the compressed air pressure is 0.7kg / cm 2 , the surface roughness after blasting reaches Sa3 level;

[0060] 4. Spraying metal ceramic coating

[0061] Use a supersonic flame spray gun to spray a cermet coating 2 on the surface of the door lever 1, and the material is NiCr-Cr 2 C 3 Spraying powder; the flame center line of the spray gun intersects the axis of the workpiece perpendicularl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com