Method for extracting palladium sponge from silver electrolysis anode slime parting liquid

A technology of anode slime and palladium sponge, applied in the direction of improving process efficiency, etc., can solve the problems of low process yield, poor working conditions, high impurities in palladium intermediate products, etc., and achieve the effect of simple operation, easy promotion and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

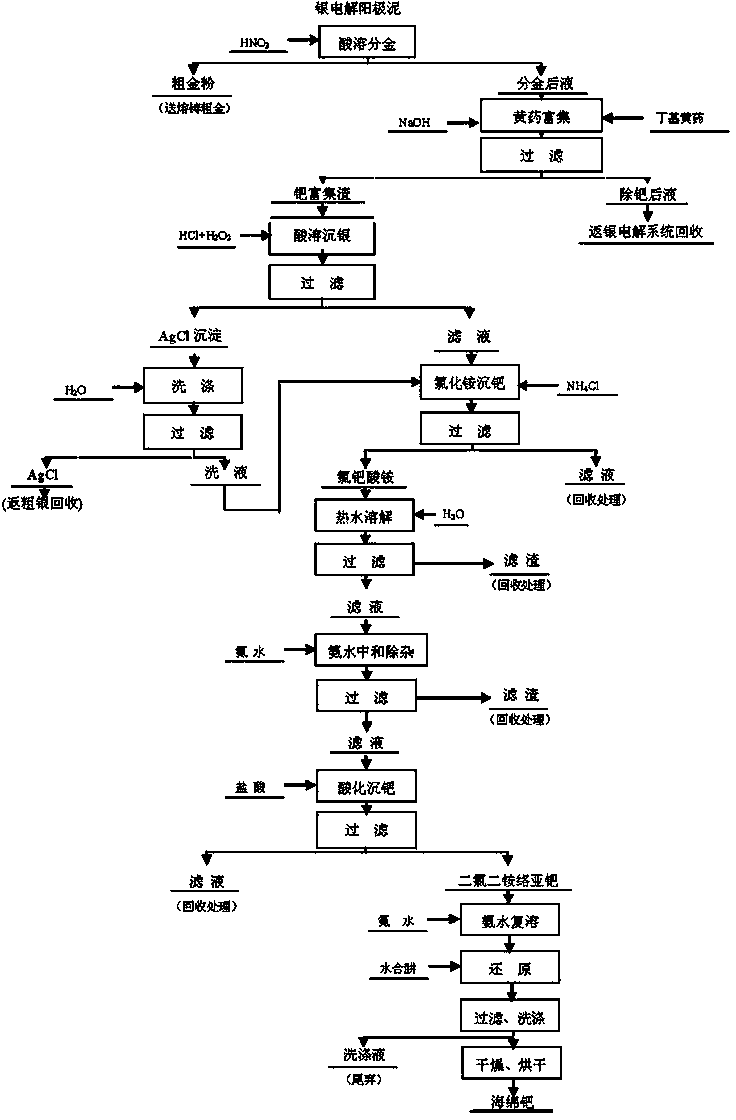

[0035] A method for extracting palladium sponge from silver electrolysis anode slime gold separation liquid, is characterized in that:

[0036] Using silver electrolysis anode slime as raw material, after the gold is dissolved and separated by nitric acid, the palladium and silver in the liquid after gold separation are recovered and extracted; the method includes the following steps:

[0037] Step 1: Xanthate Enrichment

[0038] will be 0.5 m 3 Transfer the silver electrolytic anode slime gold separation liquid containing 6.85g / L palladium into the enamel reaction kettle, adjust the silver electrolytic anode slime gold separation liquid with NaOH to pH=0.5~4.5, the best pH=1.0, and raise the temperature , add xanthate dissolved in deionized water at the same time, the quality of adding butyl xanthate is 1.0 to 5.0 times the theoretical amount of palladium and xanthate complexation reaction, and the optimal xanthate amount is 3.0 times the amount of palladium in the solution;...

Embodiment 2

[0057] The silver electrolysis anode slime gold solution contains 1.7g / L of Pd, and the enrichment reaction temperature of xanthate is 85℃. Other operating conditions and process are described with embodiment 1. The purity of the sponge palladium product obtained in this process is: Pd: 99.992%, Au: 0.0017%, Ag: 0.0020%, Cu: 0.0009%, Ni: 0.0002%; Fe: 0.0005%, Pb: 0.0004%, reaching GB1420-89 standard . The recovery rate of palladium in the process reaches 96.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com