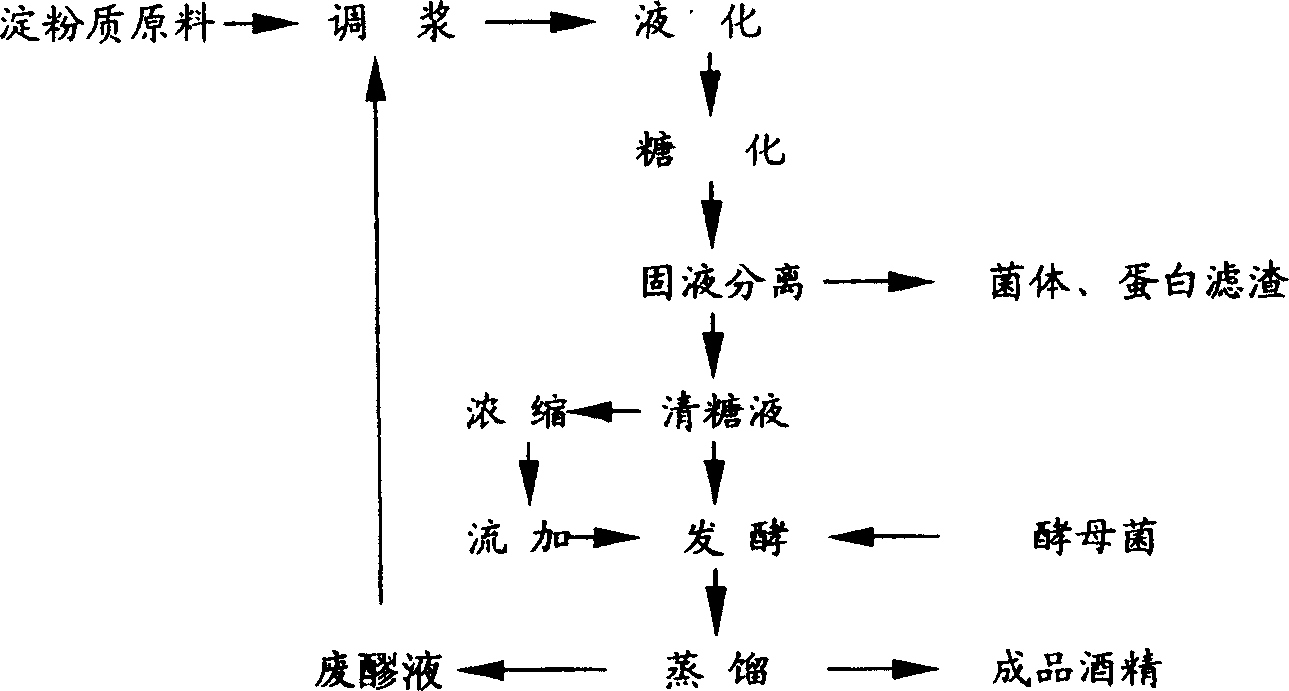

Closed cycle technique for producing alcohol in high concentration through fermentation of clear solution

A closed-loop, high-concentration technology, applied in fermentation, biofuels, etc., can solve the problems of large investment, difficult implementation of small and medium-sized alcohol factories, high operating costs, etc., to eliminate serious pollution, improve equipment utilization, and achieve zero emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In the embodiment of the present invention, the starchy raw material is industrial starch: 180g is mixed with distilled waste mash and 800ml of tap water for pulping; then heated for liquefaction and saccharification, the liquefaction and saccharification methods are not limited, but the double-enzyme continuous jet liquefaction process is the best Excellent, liquefaction temperature: 95°C, liquefaction holding time: 60 minutes, add 12U of high temperature resistant enzyme α-amylase per gram of starch during liquefaction, quickly cool down to 62°C, add 180U of glucose per gram of starch during saccharification Enzyme, saccharification for 12 hours; after saccharification, the temperature is raised to 80°C, and the solid-liquid separation operation is performed by filtration while it is hot, to remove yeast, coagulated protein and other insoluble solids in the sugar solution. The solid-liquid separation method is not limited, but requires Can obtain clear sugar solution 8...

Embodiment 2

[0024] In the embodiment of the present invention, 1700 g of corn endosperm powder is taken as the starchy raw material, 4500 ml of the previous batch of distillation waste liquid is added, 14 U of high-temperature-resistant α-amylase is added per gram of starch, heated after stirring, and liquefied at 95 ° C for 50 minutes in vacuum flash evaporation; Rapidly cool down to 62°C, add 200U of glucose glucoamylase per gram of starch, keep warm at 62°C for saccharification for 9 hours, heat up to 80°C after saccharification, and filter while hot to obtain 4725ml of clear sugar solution with a sugar concentration of 25.9% (w / w ); the clear sugar solution was divided into two parts, one part was diluted with water to a sugar concentration of 16% (w / w), cooled to 32°C, and 8% (v / v) of expanded alcoholic yeast was added for constant temperature culture and fermentation, and the other Part of the sugar solution is concentrated to 36.5% (w / w), and the concentrated sugar solution is added...

Embodiment 3

[0026] In the embodiment of the present invention, the starchy raw material takes 7800kg of low-fat corn flour, and adds 24m of the last batch of distillation waste liquid 3 , add 16U high-temperature-resistant α-amylase per gram of starch, heat evenly after stirring, keep warm at 95°C for liquefaction for 50 minutes, and vacuum flash evaporate; quickly cool down to 62°C, add 220U glucose glucoamylase per gram of starch, keep warm at 62°C for saccharification for 9 After saccharification, the temperature was raised to 80°C, filtered while hot, and 23.4m of clear sugar solution was obtained. 3 , sugar concentration 26.3% (w / w); the clear sugar solution is divided into three parts, one part is diluted with distillation waste liquid and water to a sugar concentration of 16% (w / w), cooled to 32°C, and 8% (v / v) is fermented by the expanded cultivation of alcoholic yeast, and the other two portions of clear sugar liquid are concentrated to 34% (w / w), and the concentrated sugar liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com