Organic material shell with metal texture and coating method thereof

An organic material, metal texture technology, applied in metal material coating process, cabinet/cabinet/drawer parts, sputtering coating, etc., can solve the problem of wear resistance, surface gloss, fingerprint resistance and dirt resistance Unsatisfactory, performance is not outstanding and other problems, to achieve the effect of strong wear resistance, strong film stability, high surface gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

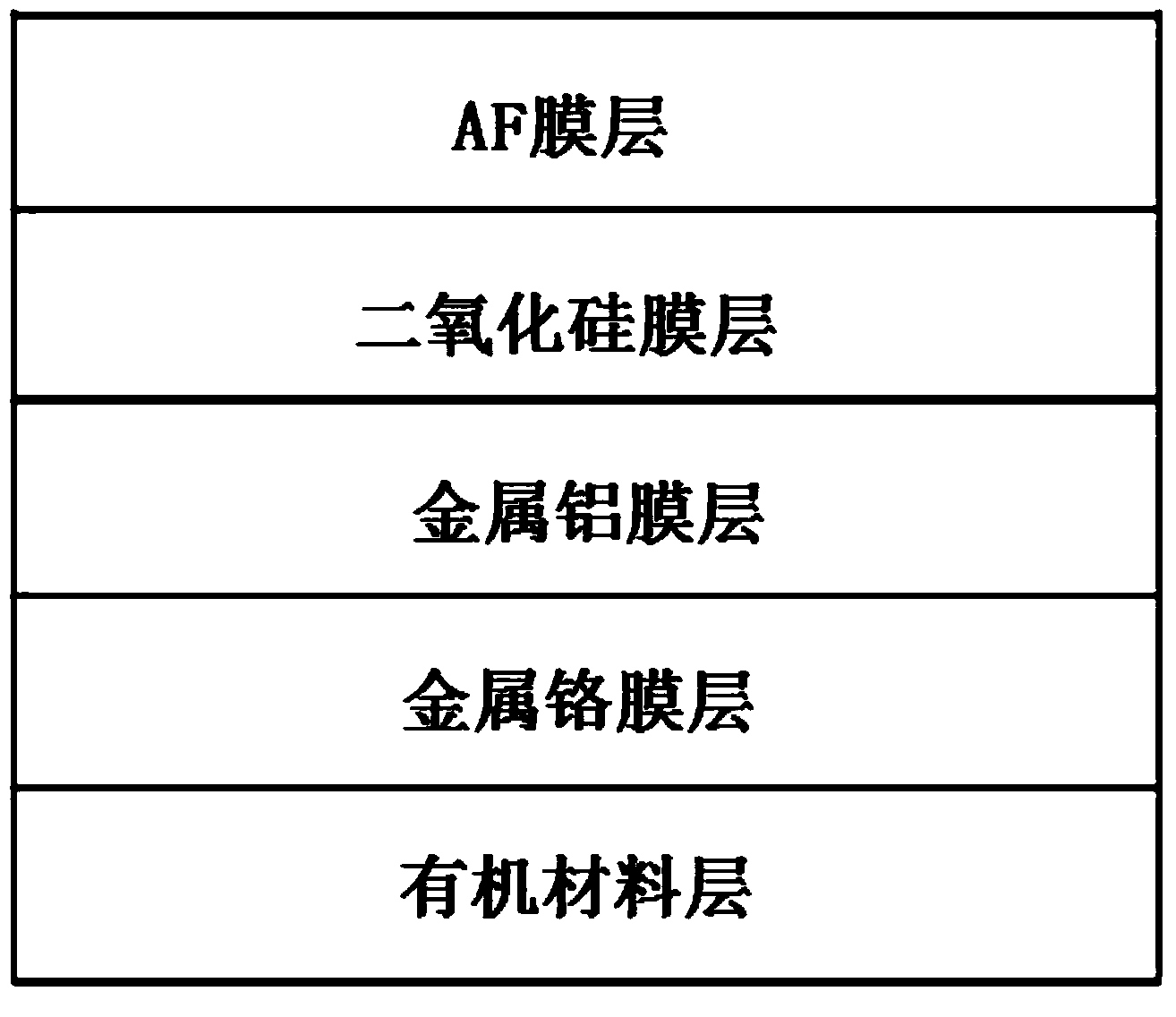

[0036] Such as figure 1 As shown, it is a metal-like organic material housing according to this embodiment, which includes a metal chromium film layer, a metal aluminum film layer, and a silicon dioxide film layer stacked on the organic material layer from bottom to top. . AF film layer, wherein the organic material layer is composed of one or more organic materials.

[0037] In this embodiment, the surface composition of the organic material layer is changed according to the mechanism of ion diffusion, and the organic material layer is placed in the anti-evaporation film device at a certain temperature, vacuum degree and time, and the target is ionized under the bombardment of the electron gun. , metal ions are deposited on the surface of the organic material layer due to diffusion, so that the surface of the organic material layer presents a metallic texture. And the arrangement of the metal chromium film layer and the metal aluminum film layer can make the glossiness of th...

Embodiment 2

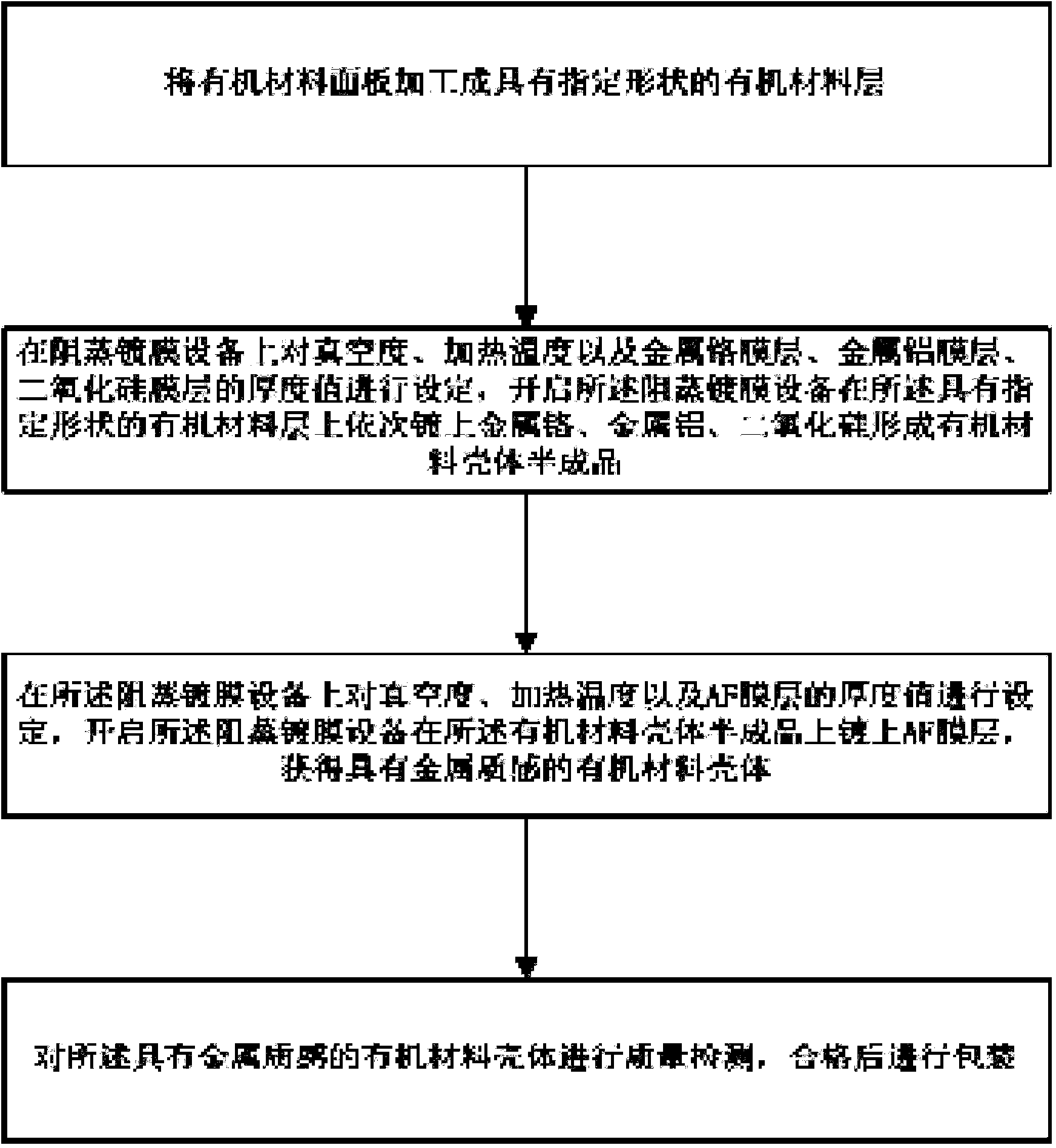

[0044] Such as figure 2 As shown, in order to comply with the coating method of an organic material shell with a metallic texture described in this embodiment, the following steps are included:

[0045] S1: Process the organic material panel into an organic material layer with a specified shape;

[0046] S2: Set the vacuum degree, heating temperature, and the thickness values of the metal chromium film layer, metal aluminum film layer, and silicon dioxide film layer on the evaporation resistance film equipment, and turn on the evaporation resistance film equipment in the specified shape. Metal chromium, metal aluminum and silicon dioxide are sequentially plated on the organic material layer to form a semi-finished organic material shell;

[0047] S3: Set the vacuum degree, heating temperature and the thickness value of the AF film layer on the evaporation resistance film device, turn on the evaporation resistance film device to coat the AF film layer on the organic materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com