High-temperature alloy plate drawing method

A high-temperature alloy and sheet metal technology, which is applied in the field of deep-drawing of existing high-temperature alloys, can solve problems such as cracked parts and strains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

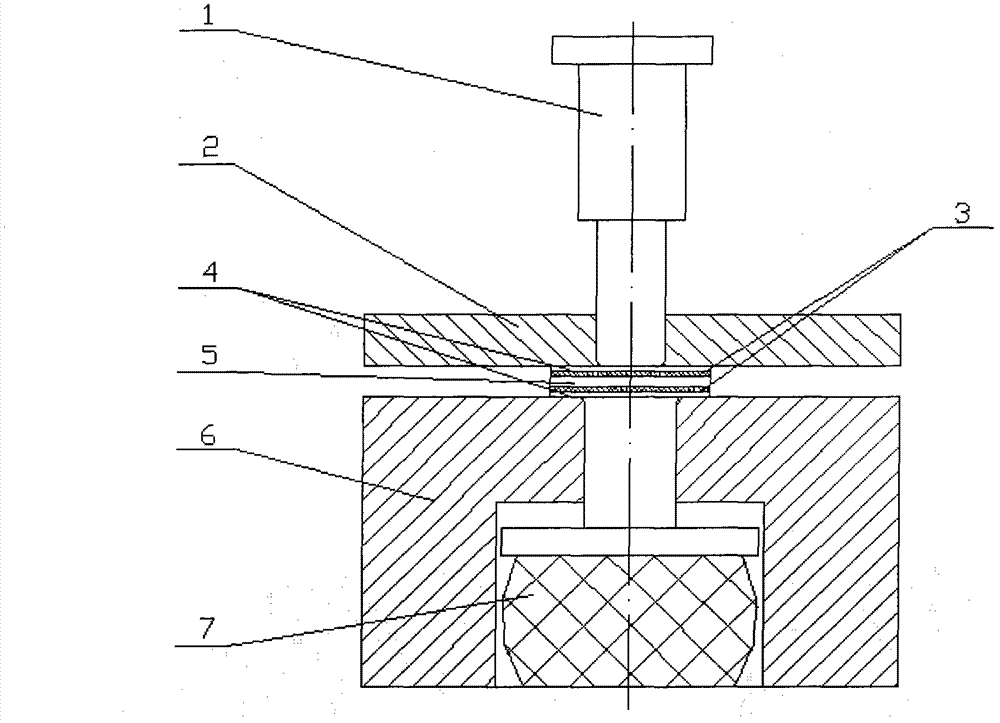

[0007] The method for deep-drawing a superalloy sheet of the present invention will be further described in detail with reference to the embodiments described in the accompanying drawings.

[0008] exist figure 1 In the embodiment of the present invention, the upper and lower surfaces of the superalloy sheet 5 are evenly coated with lubricating oil 3, and then covered with a protective film 4 of the same size as the superalloy sheet 5, and then placed on the press with a punch 1. Deep-draw the high-temperature alloy sheet 5. During processing, the binder plate 2 presses the outer ring of the high-temperature alloy sheet 5, and the inner ring metal flows into the die 6 to reach a certain depth, and the ejector mechanism 7 will draw the part ejected.

[0009] During deep drawing, the internal interaction of the blank occurs due to the force on the blank, which causes tensile stress in the radial direction and compressive stress in the tangential direction inside the material. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com