Multipoint forming die based on solid particle medium back pressure

A solid particle, multi-point forming technology, used in the field of stamping dies, can solve the problems of difficult to solve sealing problems, uniform back pressure, etc., to prevent leakage, uniform pressure, and improve the degree of sheet metal deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

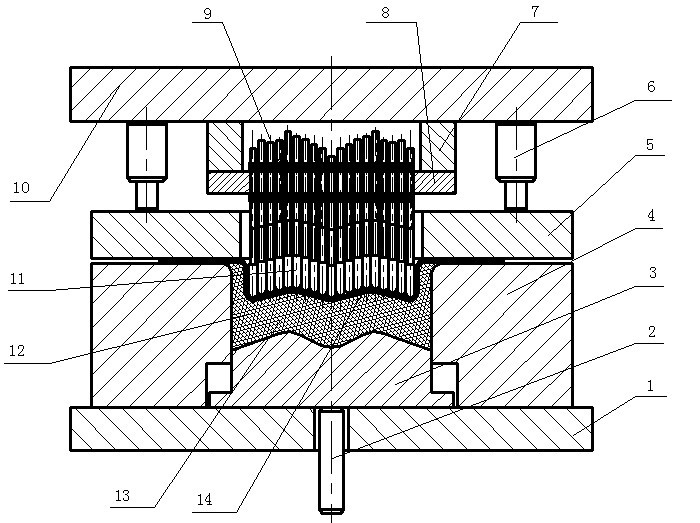

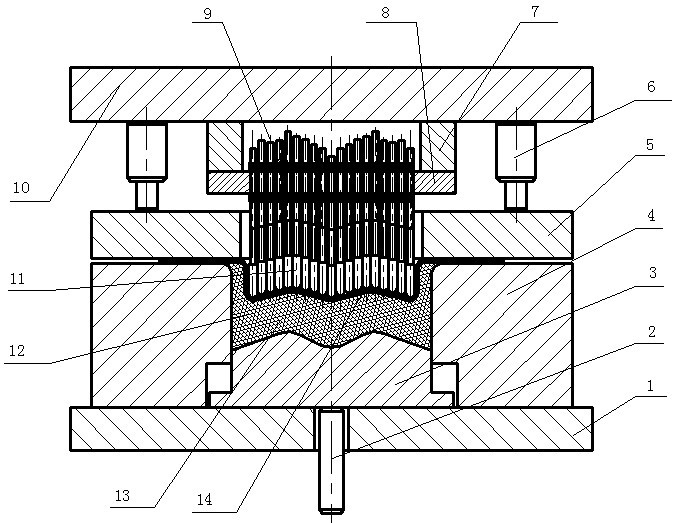

[0010] See figure 1 , Is a multi-point forming mold based on the back pressure of solid particle media of the present invention, which includes a lower mold base 1, an ejector rod 2, a cushion block 3, a concave mold 4, a pressing plate 5, a cylinder 6, a shim 7, and a support plate 8, bolt 9, upper mold base 10, punch 11, solid particles 12 and blank 14, etc.; die 4 is installed on the lower mold base 1, the cylinder 6 is installed on the upper mold base 10, the cylinder shaft of the cylinder 6 (working end 1) Contact with the upper surface of the pressing plate 5, when the cylinder 6 is working, its cylinder axis will be extended or shortened, pushing the pressing plate 5 to move correspondingly to generate clamping pressure; the support plate 8 is installed on the shim 7 and the shim 7 is installed On the upper mold base 10, a cavity is provided in the support plate 8 to allow a number of bolts 9 to pass through the cavity; the spacer 3 is provided in the cavity in the middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com