Prepn of columnar superfine crystal material

An ultra-fine-grained and columnar technology, applied in the field of preparation of columnar ultra-fine-grained materials, can solve the problems of high tonnage of equipment and low degree of deformation, and achieve the effect of low tonnage of equipment, high degree of deformation and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

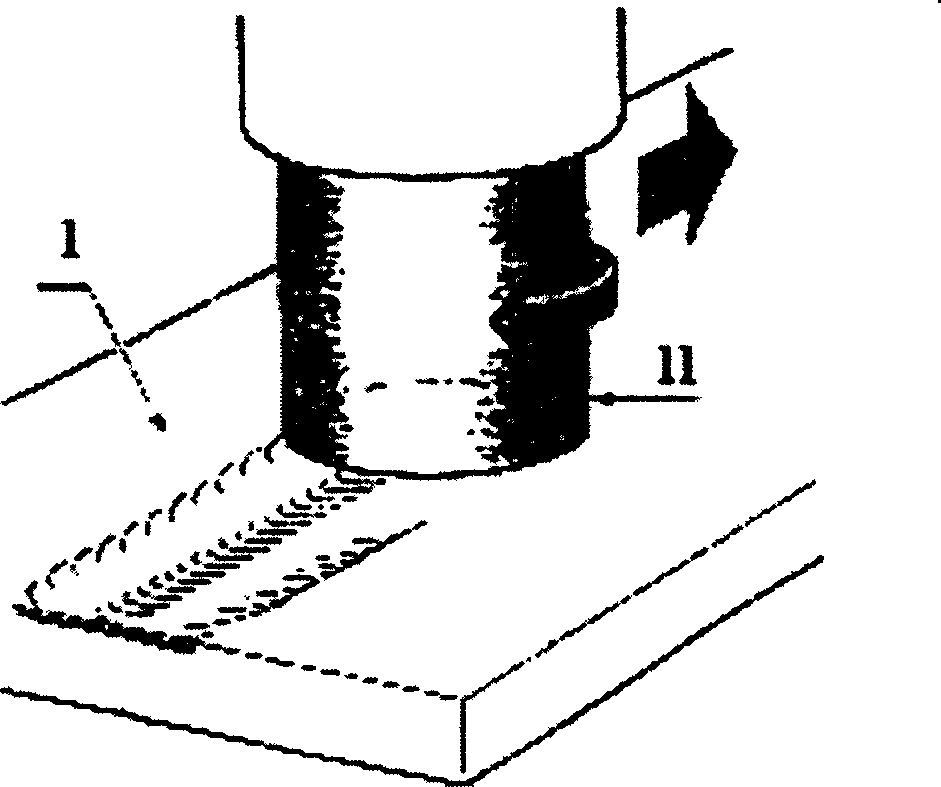

[0019] Embodiment 1: refer to figure 1 , this example belongs to a method of preparing ultra-fine-grained materials by the deformation zone transfer method. It is to use the friction, pressure and torsion lateral transfer method to prepare a large area of ultra-fine grain material on the surface of the plate metal material, and to carry out surface hardening treatment. The specific process is as follows:

[0020] The rotating speed of the used equipment for twisting head 11 should be adjustable, and can bear certain axial pressure;

[0021] First set the rotational speed of the twisting head 11 to 200-500r / min, start the machine, make the twisting head 11 rotate at the set speed, adjust the distance between the twisting head 11 and the material 1 to be formed, and make the twisting head 11 and the material 1 close contact.

[0022] The moving mechanism is started to make the pressing and twisting head 11 move relatively laterally on the material 1 at a moving speed of 20...

Embodiment 2

[0026] Embodiment 2: refer to Figure 4 , this example is the preparation of rod-shaped ultra-fine-grained material by thermal torsion migration method, which belongs to a method of preparing rod (block)-shaped ultra-fine-grained material by deformation zone transfer method. The specific process is as follows: the rod-shaped metal material 1 to be refined is stuck between the fixed fixture 10 and the rotating fixture 3 . The rotary clamp 3 is driven by a servo motor 4 , and a torque sensor 41 is installed between the rotary clamp 3 and the servo motor 4 . The induction coil 7 and the intermediate frequency power supply 6 can locally heat the rod-shaped metal material 1 . The cooling ring 45 and the cooling system 8 can locally cool the rod-shaped metal material 1 . The temperature sensor 5 is used to measure the temperature of the heating zone.

[0027] The rod-shaped metal material 1 is locally heated by the intermediate frequency power supply 6 and the induction coil 7, a...

Embodiment 3

[0033] Embodiment 3: refer to Figure 5, this example is the preparation of columnar ultra-fine-grained materials by the frictional pressure-torsion axial transfer method, which belongs to another method of preparing ultra-fine-grained materials by the deformation zone transfer method. The specific process is as follows: put the rod-shaped metal material 1 to be refined into the cooling sleeve 55, make the rod-shaped metal material 1 closely contact with the bottom of the cooling sleeve 55, and the rod-shaped metal material 1 is driven by the machine at the bottom of the cooling sleeve 55 at a high speed. Rotate and apply some pressure. The rod-shaped metal material 1 at the contact end surface undergoes severe shear plastic deformation, and the crystal grains are fragmented to form a torsional deformation layer 56 . At the same time, cooling water is injected into the water cooling chamber 54 of the cooling sleeve 55 through the water inlet 52 , and the cooling water is disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com