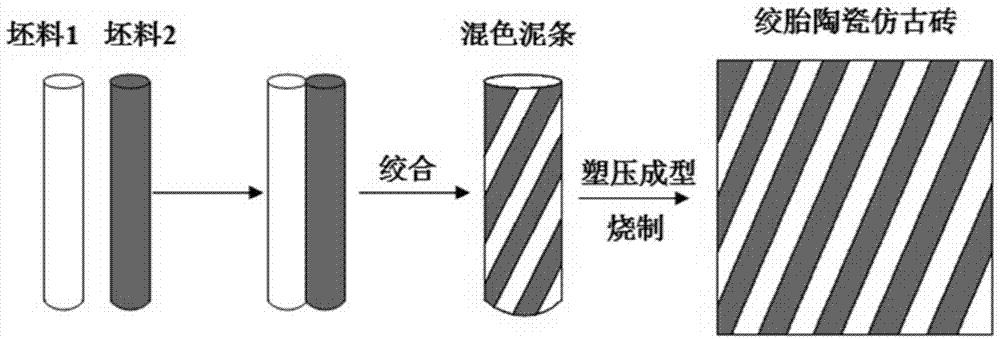

Preparation method of twisted pottery archaized bricks

A technology for antique bricks and ceramics, applied to clay products, other household utensils, household utensils, etc. It can solve the problems of gradation requirements for powder materials, low production costs, narrow firing temperature range, etc., and achieve simple molding methods and water absorption. The effect of low rate and low firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of manufacture method of twist tire ceramic antique brick, the steps are as follows:

[0029] 1) The raw materials are taken according to the mass percentage: 35% of diopside, 41% of kaolin, 6% of magnesia clay, 7% of feldspar, and 11% of quartz sand, respectively crushing, passing through a 250-mesh sieve, and mixing evenly, get the mixture;

[0030] 2) Place the mixture obtained in step 1) in a vacuum mud mill and add water to refine the mud. The amount of water added is 12% of the weight of the mixture to obtain a uniform mud bar. After aging for 48 hours, a blank (Φ20mm, length 300mm) is obtained;

[0031] 3) Divide the blank obtained in step 2) into 2 parts, wherein one part is recorded as blank 1, and the other part is mixed with 3% cobalt blue material (the average particle size of the color material is 1 μm) for kneading mud to obtain colored mud strips. Obtain blank 2 (Φ 20mm, length 300mm) after melting for 48h;

[0032] 4) Twisting the blank 1 and bl...

Embodiment 2

[0037] A kind of manufacture method of twist tire ceramic antique brick, the steps are as follows:

[0038] 1) The raw materials are taken according to the mass percentage: 28% of diopside, 39% of kaolin, 9% of magnesia clay, 11% of feldspar, and 13% of quartz sand, respectively crushing, passing through a 250-mesh sieve, and mixing evenly, get the mixture;

[0039] 2) Place the mixture obtained in step 1) in a vacuum mud mill and add water to refine the mud. The amount of water added is 13% of the weight of the mixture to obtain a uniform mud bar. After aging for 52 hours, a blank (Φ30mm, length 200mm) is obtained;

[0040] 3) Divide the blank obtained in step 2) into 2 parts, wherein one part is recorded as blank 1, and the other part is mixed with 4% manganese red material (average particle size of the color material is 10 μm) for kneading mud to obtain colored mud strips, aged After 52 hours, blank 2 (Φ30mm, length 200mm) was obtained;

[0041] 4) Twisting the blank 1 an...

Embodiment 3

[0046] A kind of manufacture method of twist tire ceramic antique brick, the steps are as follows:

[0047] 1) The raw materials are taken according to the mass percentage: 23% of diopside, 45% of kaolin, 13% of magnesia clay, 9% of feldspar, and 10% of quartz sand, respectively crushing, passing through a 250-mesh sieve, and mixing evenly, get the mixture;

[0048]2) Put the mixed material obtained in step 1) in a vacuum mud refining machine and add water to refine the mud. The amount of water added is 13% of the weight of the mixed material to obtain a uniform mud bar. After aging for 64 hours, a blank (Φ20mm, length 300mm) is obtained;

[0049] 3) Divide the blank obtained in step 2) into 2 parts, wherein one part is recorded as blank 1, and the other part is added with 2% chrome-green material (the average particle size of the color material is 5 μm) for kneading mud to obtain colored mud strips, aged Obtain blank 2 (Φ 20mm, length 300mm) after melting for 64h;

[0050] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com