Liquid crystal panel and manufacturing method thereof

A technology for a liquid crystal panel and a manufacturing method, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of light leakage, easy deformation, and displacement of pads, etc. of the liquid crystal panel, so as to prevent light leakage, solve the problem of light leakage, and form a method. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

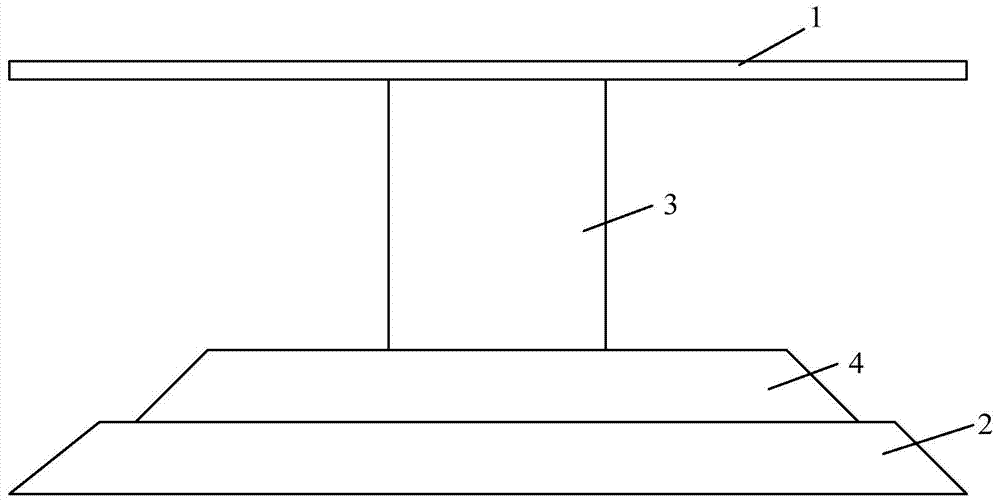

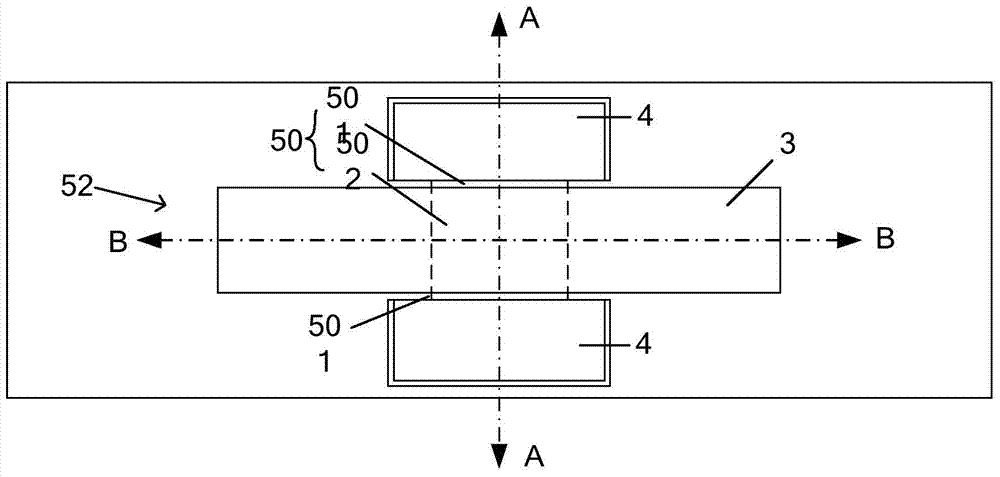

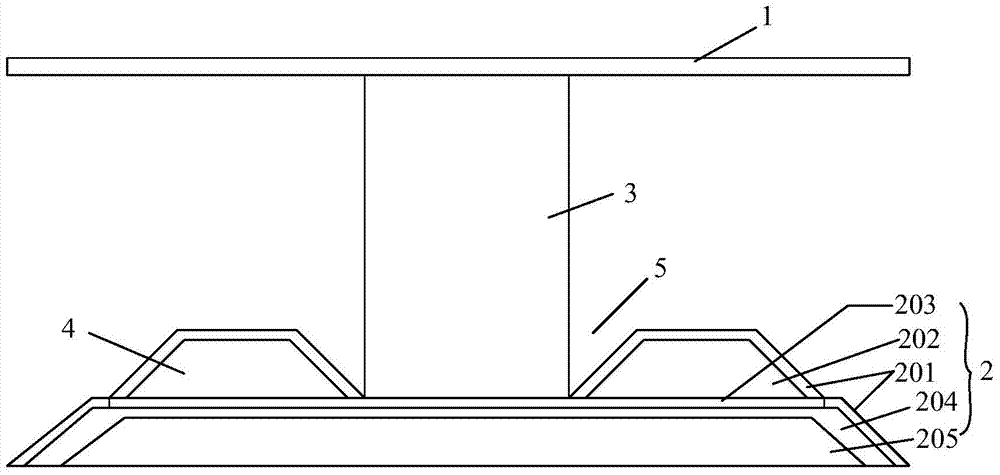

[0020] refer to figure 2 with image 3 As shown, the present invention provides a structure of a liquid crystal panel, which includes a first substrate 1 and a second substrate 2, and a support column 3 and a spacer arranged on the opposite substrate are arranged between the two substrates. 4. Between the support column 3 and the spacer 4, there are stoppers 5 for positioning in different directions, so as to prevent relative movement of the substrate. The spacer 4 is arranged above the second base plate 2, and is used to limit and fix the support column 3. The first base plate 1 is supported by the support column 3, and is supported on the first base plate 1 by the support column 3. A certain box thickness is formed between the first substrate 1 and the second substrate 2, and plays the role of supporting the box thickness when the first substrate 1 is under pressure and the box thickness decreases.

[0021] The limiter 5 is arranged in different directions of the spacer 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com