Metal bellows with axial stiffeners, and forming method

A technology of metal corrugated pipes and reinforcing ribs, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of breaking at the trough, reducing the service life of the hose, shortening the service life, etc., and achieves a simple forming method, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

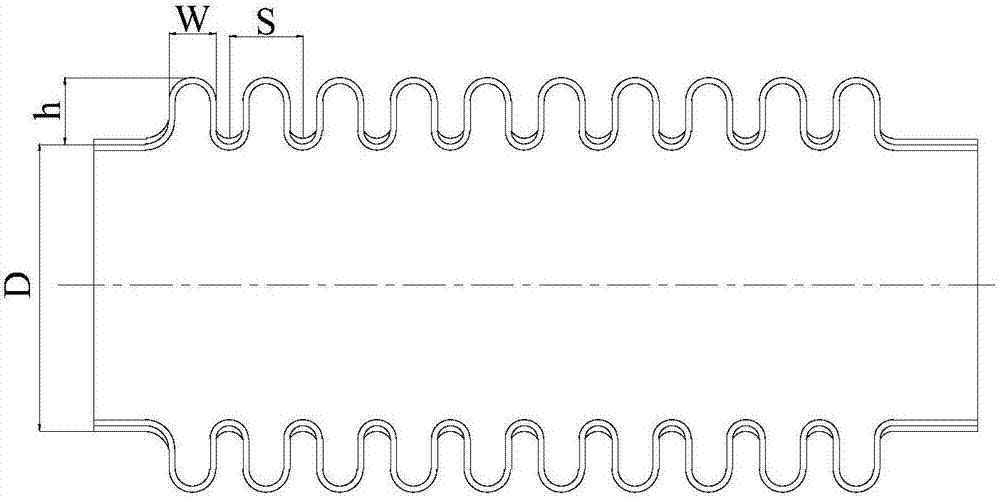

Embodiment 1

[0034] First, design the sheet size of the tube blank (including the height, width and wave number of the axial wave) according to the required corrugated metal hose, and process the upper and lower rolls according to the size, and roll on a special rolling mill, and the sheet is in the feeding machine. It is sent into the mold under the action, and the sheet is rolled into the required wavy sheet with the rolling of the roll. figure 1 shown. Afterwards, the plate is rolled and welded to form an axially corrugated tube blank as attached figure 2 shown. Among them, a corrugated hose with a nominal diameter of D = 80mm is selected, and the number of axial waves of the plate is n = 12. Therefore, the distance l between the two rolls can be determined according to the number of axial waves and the nominal diameter of the hose. 1 =20.93mm, roll radius r=2.5mm, straight edge section between two rolls l 2 =10.93mm, the arc length l of a single waveform 3 = 30.55mm. Work piece ...

Embodiment 2

[0037] The operation process is the same as that of Example 1, and the corrugated metal hose with different wave parameters (wave height and wave width), as shown in Figure 2, has a diameter of D=80mm, wave height h of 8mm, wave width of W=5mm, and wave number n=20 The flexural rigidity of the metal bellows with reinforced ribs is calculated to be 3.92MN·m. And the common metal bellows with diameter D=80mm, wave height h is 8mm, wave width W=5mm, wave number n=20 without reinforcement ribs, its flexural rigidity is calculated to be 2.11MN·m. Therefore, the new metal bellows with ribs has greater bending stiffness, and at the same time avoids the damage caused by the mutual extrusion between the waves.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com